The expert's opinion

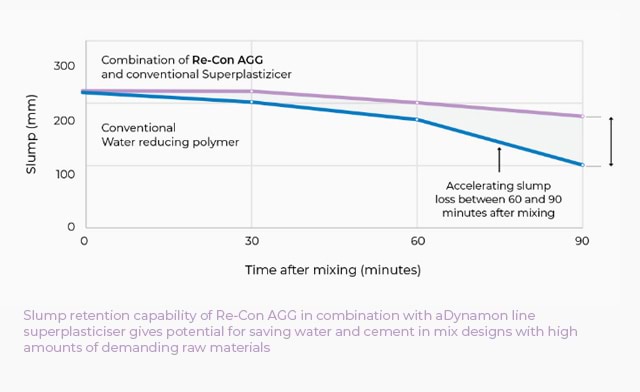

The admixtures play a key role in reducing the embodied carbon content of concrete through innovative products such as Low Carbon Concrete Admixtures (LCCA). These formulations optimise hydration, enabling lower cement content or higher dosage of Supplementary Cementitious Materials (SCM) while maintaining high performance. The use of Mapecube 60W…

The admixtures play a key role in reducing the embodied carbon content of concrete through innovative products such as Low Carbon Concrete Admixtures (LCCA). These formulations optimise hydration,…