ZAMASWAZI NTOBELA– PRODUCT MANAGER OF PRODUCTS FOR CERAMIC, PORCELAIN AND STONE MATERIALS AT MAPEI SOUTH AFRICA PROVIDES INSIGHT ON EPOXY GROUTS.

What are the main characteristics of epoxy resin-based grouts?

Epoxy resin-based grouts are generally two-component products which are rigid, chemical resistant, impermeable and resistant to compression.

When should you use epoxy grouts?

For grouting and tiling areas that will be exposed to chemicals, for example in the food and beverages industry: dairies, breweries and similar sectors, or even for worktops in domestic kitchens. In such cases, any food or acids that inevitably come into contact with the grout will not be able to attack it chemically and erode it.

Is it difficult to use resin-based products?

Not anymore. A lot of progress has been made in the field of chemical products for the building industry and we are now able to produce water based, two-component, epoxy resin-based grouts with a creamy consistency, which makes them much easier to use and clean off surfaces.

What are the most important steps when using epoxy grouts?

1. The two components that make up the grout must be mixed together thoroughly and completely. This operation needs to be carried out very carefully, if possible with an automatic mixer at low-speed, making sure the two components in the product are amalgamated correctly. We recommend you don’t divide the components (that is, use only partial quantities of the two components), otherwise the product may not harden correctly, and its chemical characteristics could be affected.

2. Within a few minutes of filling the joints with product, the floor or wall covering must be cleaned with water.

3. Open time is one of the most critical application factors when applying epoxy products. Once you have mixed the epoxy, you only have between 30-45 minutes to use the entire bucket. When the open time has been exceeded, the product will not set or cure.

In which cases should you not use resin-based grout?

There aren’t any particular technical limitations to using it, but normally you shouldn’t use epoxy resin for particularly porous tiles or stone. Why? Because the grout could be deposited in the pores of the material and you wouldn’t be able to remove it.

So, when all’s said and done, is resin grout better than cementitious grout?

No, the difference rather depends on each site’s specific needs. If there is a risk of aggression from acids then we use resin, in all other situations cement has excellent performance properties.

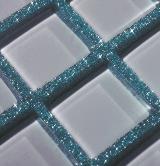

The family of epoxy grouts made by Mapei is called KERAPOXY. Amongst these products, KERAPOXY CQ is used for joints 3 mm wide and above, while KERAPOXY DESIGN has been specifically developed for grouting mosaic with joints up to 3 mm wide.

These are highly reliable, technological products with high performance properties and the extra attention required during the preparation and cleaning phases is justified by the end result: quality and durability of the highest order.