Purpose and Properties of Sealants

The main function of sealants is to seal these joints to prevent entry of unwanted substances such as dirt and liquids. They are also used for sealing penetrations, and to fill gaps and cracks in facades for weatherproofing and/or aesthetics purposes.

Sealants should have the following general properties:

- Impermeable to water

- Long term elasticity, good recovery of size and shape when subjected to cyclic deformations

- Durable, can withstand ageing, weathering degradation and other environmental service conditions, especially in external applications

- Strong adhesion to joint flanks, able to bond well with building surfaces

- Cohesion strength, elongate within the joint’s designed movement capacity without breaking

- Non-toxic, safe to use

- Cure to a non-tacky finish, does not trap dirt.

Depending on site conditions and requirements, sealants can have other special or additional properties that include:

- Continuous immersion in water, for use in swimming pools, water storage tanks, etc.

- Chemical resistance, for use in kitchens, industrial plants, etc.

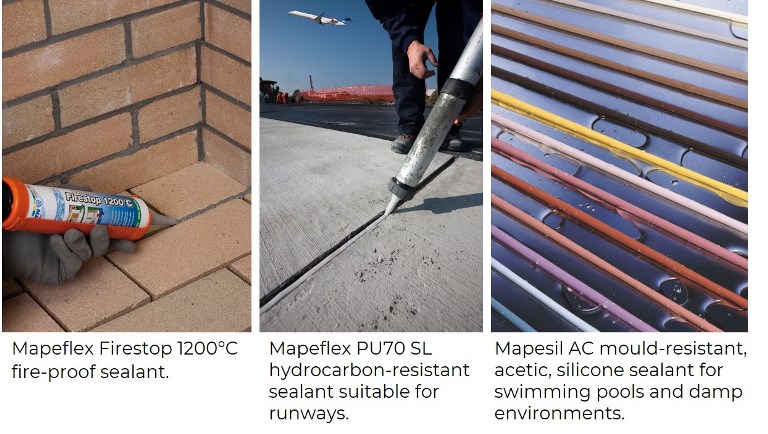

- Resistance to fuel, oils and lubricants, for use in car parks, airport aprons, driveways, etc.

- Low Volatile Organic Compounds (VOC), for use in cleanrooms subject to ISO 14644 standards

- Resistance to high temperatures or fire, for use in refractories, fire-break walls, etc.

Reasons for joint sealant failures

There are many possible reasons for sealant failures. Let’s take a look at them:

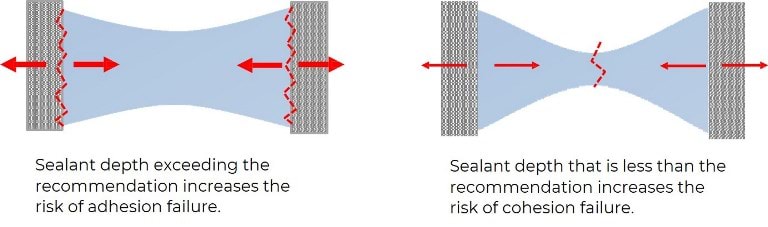

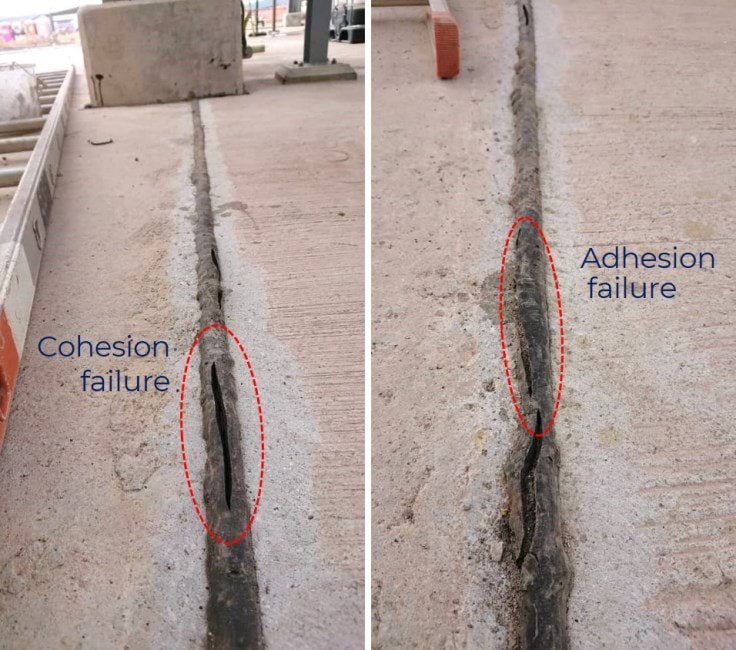

- Applying the wrong width/depth ratio. It is important to install the sealant according to the width/depth ratio recommended by the manufacturer. If the sealant depth exceeds the recommendation, the increased stress build-up during elongation is transferred to the adhesion faces, with correspondingly increased risk of failure. On the other hand, if the sealant depth is less than the recommendation, the risk of sealant cohesion failure is increased.

- Poor substrate preparation. Substrates which are dusty, crumbly, or contaminated with oils or grease interfere with sealant adhesion and result in weak bonds.

- Non-priming of substrates. Manufacturers recommend priming to help consolidate the substrate and improve adhesion, especially on porous surfaces. Failure to do so may result in weakened adhesion.

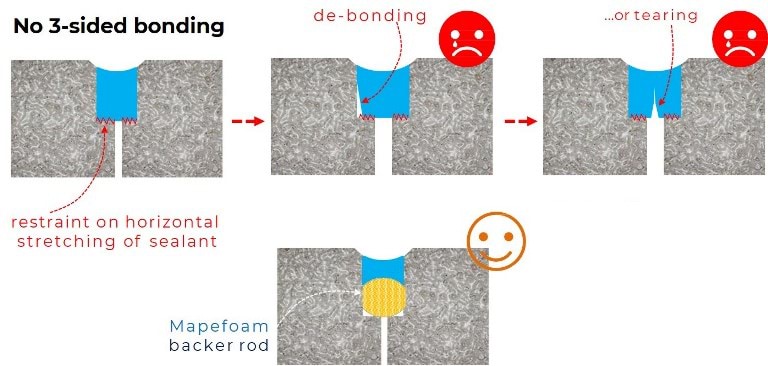

- 3-sided bonding. Sealants for movement joints must be bonded on two flanks only. 3-sided bonding restrains the sealant from stretching and its ability to cope with cyclic deformations. This results in de-bonding or tearing of the sealant over time.

- Improper joint design/construction. The joint design/construction is insufficient to accommodate the movement based on the joint spacing, the temperature differential between minimum and maximum, and the coefficient of thermal movement of the substrate.

- Wrong sealant selection. This happens when the selected sealant (i) does not have the movement capability to accommodate the joint design, (ii) is not compatible with the substrate (iii) does not have the resistances to withstand the service conditions.

Criteria for selecting Sealant

- Function of the sealant. Is the sealant intended to fill gaps and cracks or is it applied to form watertight movement joints on floors and facades? Understanding its function is important in deciding sealant selections. Contraction joints are gaps designed to regulate cracking to accommodate contraction of concrete. Expansion joints are designed to isolate structural units that behave differently and are used to prevent crushing and distortion caused by compressive forces by applied loads or differential movements. Construction joints are formed by interruptions in the placement of concrete or due to the positioning of precast units. Sealants are selected based on their technical capabilities such as elongation, movement capability, etc.

- Joint movement. The expected joint movement is calculated based on the structure’s exposure to thermal deformations (depending on temperature fluctuations, thermal coefficient of the substrate, and joint spacing). The sealant must have the required movement capability.

- Substrate type and sealant compatibility. It is important to check the compatibility of the substrate and sealant material beforehand. In addition, the substrate and joint surfaces must be clean, dry and free of defects such as loose aggregates, spalls and cracks that could impair the sealant bond.

- Location of the joint. Is the joint located in an indoor or outdoor setting?

- Service conditions. Do the site conditions require special sealant characteristics? For instance, sealants for refractories must be able to resist high temperature, and sealants for swimming pools and water storage tanks must be able to withstand immersion in water. Building certifications and other special conditions also influence the selection of the sealant.

Combining the right type of sealant with the proper design, appropriate joint detailing, correct installation method, and regular maintenance will go a long way towards maintaining the integrity of the structure.

Mapei offers a wide range of sealants made from various types of polymers, each one characterized by specific performance characteristics in terms of elasticity, and resistance to stresses and loads for all types of site conditions. Visit our website for more information on our Sealants range.