Búsqueda por líneas de productos

Búsqueda por líneas de productos

Todas las líneas de productos

Todas las líneas de productos

Búsqueda de productos

Búsqueda de productos

En el foco

En el foco

Vaya a HERRAMIENTAS Y DESCARGAS

Vaya a HERRAMIENTAS Y DESCARGAS

Biblioteca técnica

Biblioteca técnica

Dónde comprar

Dónde comprar

Instaladores profesionales de Mapeheat

Instaladores profesionales de Mapeheat

Garantías

Garantías

Paleta de colores de lechada/masilla

Paleta de colores de lechada/masilla

Herramientas para arquitectos

Herramientas para arquitectos

CADs/Especificaciones

CADs/Especificaciones

Salud y Ambiente

Salud y Ambiente

Biblioteca de videos

Biblioteca de videos

Productos BioBlock de MAPEI

Productos BioBlock de MAPEI

Biblioteca de información de producto

Biblioteca de información de producto

Calculadoras de producto

Calculadoras de producto

De Realtà Mapei n.° 33 - 5/10/2021

In all the years that MAPEI has been in existence, one fundamental constant has always been true: Change is inevitable. From MAPEI’s beginnings back in 1937 in Milano, Italy, to the present, materials used in construction have changed significantly to make them safer to use, easier to install and, most importantly, better at performance. The key to success in managing this change is to be on top of the market, to be aware of trends and to respond rapidly in developing new products at the forefront of customer demand.

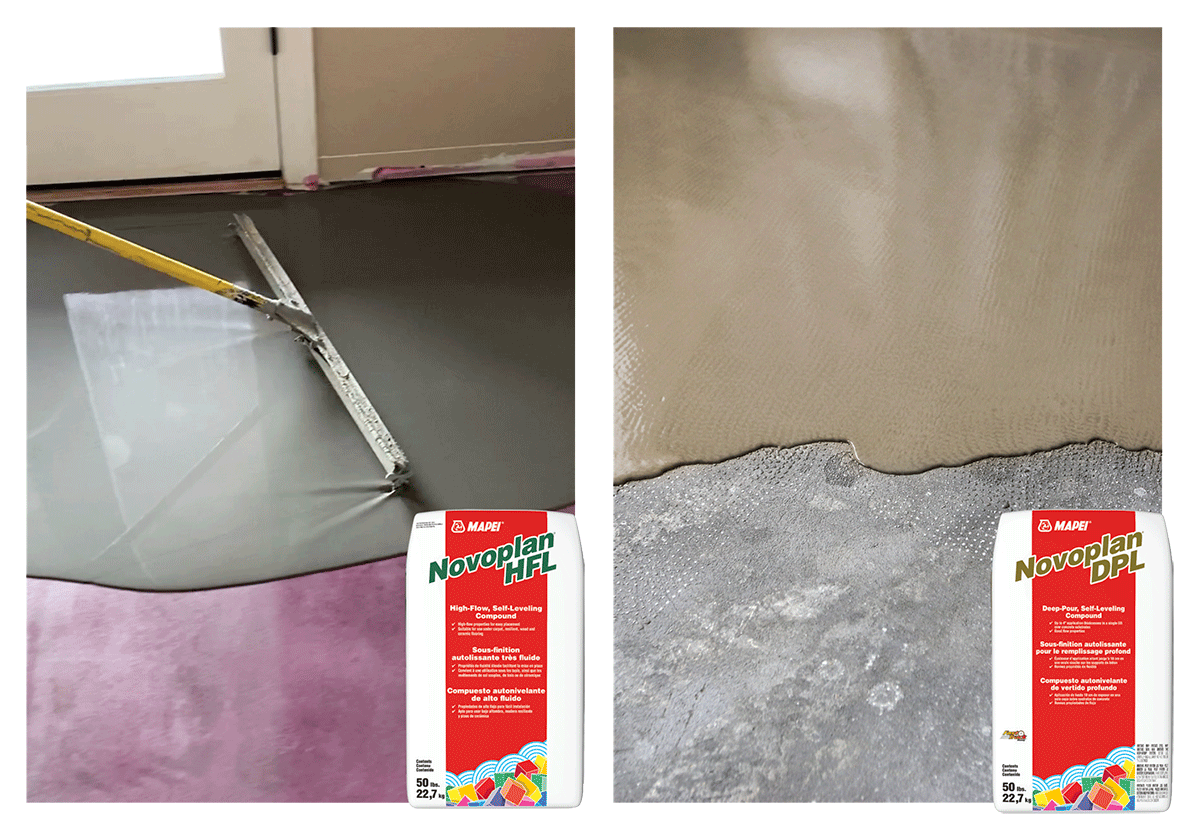

At MAPEI, the driver behind this success is our extensive R&D group, which works diligently behind the scenes to formulate the next marvel of technology for previously unimagined performance. Two of those innovations can be found in MAPEI’s recent introduction of Novoplan HFL high-flow self-leveling compound and Novoplan DPL deep-pour leveler.

Having a perfectly flat and pristine substrate can allow for the most stunning floor projects seen in both residential and commercial applications. The best way to achieve this perfectly flat substrate is invariably through the use of self-leveling compounds.

Self-leveling compounds are remarkable formulations and, in the hands of a skilled professional, can really make the difference in a floor-covering installation. But it is important to note the term “skilled professional.” The proper installation of self-leveling compounds may look easy, but it requires a great deal of skill and collaboration to accomplish.

Novoplan HFL, on the other hand, can make just about anyone look like a professional installer thanks to its very high flow and leveling characteristics. After using Novoplan HFL on a project, contractors have given such reviews as “super fluid,” “places itself,” “no need to use a spike roller or even a smoother,” and “finished material very flat and defect-free.” Anytime you get these kinds of quotes from contractors using your products, you know you have really developed something unique. Novoplan HFL is just that: Mixing easily with water, flowing out faster and farther than any other self-leveling compound, drying to a very flat surface and offering a final compression strength in excess of 4,500 psi (31.0 MPa). We believe that Novoplan HFL will be a major hit in the subfloor preparation category because of these exciting attributes.

Novoplan DPL deep-pour leveling compound, another new and exciting development from MAPEI, addresses this challenge: How to fill areas up to 4" (10 cm) in depth in a single application. Admittedly, such a situation is not terribly common, but when flooring contractors are faced with this challenge, currently available remedies are not very user-friendly.

Typically, to handle a deep application up to 4" (10 cm) in depth, a typical solution is to extend a self-leveling underlayment (SLU) with pea gravel from 3/8" to 3/4" (10 to 19 mm) in diameter. This aggregate must be brought to the jobsite and placed at up to 50 percent of the anticipated final thickness. (For help in doing so, see MAPEI’s online installation guide “Extending SLUs with aggregate”.) Once all this aggregate is carried in and placed, the leveling compound is mixed and poured over the gravel. Then, the leveler is “raked” into the aggregate in order to mix everything in together. This can obviously be time-consuming and back-breaking work.

Another traditional option is to place multiple layers of self-leveling compounds to achieve the final depth. Most common self-leveling compounds can be applied in thicknesses ranging from 1/2" to 2" (12 mm to 5 cm). If you used a leveling compound with a maximum application thickness of 1" (2.5 cm) to fill 4" (10 cm) in depth, you would have to prepare, mix and apply that leveling compound four times to achieve the final thickness… and each layer would have to dry to completion before the following layers can be applied.

Novoplan DPL deep-pour leveling compound changes all that, allowing for thick repairs in a single pour up to 4" (10 cm) in depth. This product gives flooring contractors a single-pour solution, saving them an extraordinary amount of time and labor.

There are, however, some nuances to the installation of Novoplan DPL that are important to note. You simply can’t place Novoplan DPL like you might with a garden hose in a swimming pool, leaving the hose in one corner while the entire pool fills up. Novoplan DPL has, beyond its deep-fill characteristic, great flow properties as well, so if you are barrel- or pump-mixing, Novoplan DPL is going to spread out evenly over the properly prepared substrate. What you don’t want is for Novoplan DPL to start setting up while you are trying to fill the repair.

Novoplan DPL has good working properties up to 15 to 20 minutes. However, after that it will start to gel and set up. If you are constantly pouring material into the same area to “fill the pool,” that gelling property will start to affect how the leveler flows out. Therefore, we highly recommend restricting the flow of Novoplan DPL to areas of 100 to 150 square feet (9.29 to 13.9 m2) at a time with the use of temporary dams or dikes. This will allow you to control the placement of Novoplan DPL and achieve a flat, finished surface.

Once a pour of Novoplan DPL has set, you can remove the temporary dams, move them to the next section and pour the next section. This process is repeated until the area is completely filled. The cold joints created can be easily treated using one of MAPEI’s many skimcoating or patching compounds.

In summary, Novoplan HFL and Novoplan DPL represent some of the amazing brainpower in MAPEI’s R&D group, as well as the invaluable influence of our sales team and customer base. I encourage you to reach out to your favorite MAPEI contact point to find out more about these two exciting SLUs.

About the author:

Jeffrey B. Johnson

Jeff is the Business Manager for MAPEI’s Floor Covering Installation Systems line. Jeff brings to the industry more than 30 years’ experience in the development and marketing of floor-covering installation products. Practical experience in the construction industry and as a bench chemist gives Jeff an insightful perspective on surface preparation, moisture mitigation and floor-covering installation.