Búsqueda por líneas de productos

Búsqueda por líneas de productos

Todas las líneas de productos

Todas las líneas de productos

Búsqueda de productos

Búsqueda de productos

En el foco

En el foco

De Realtà Mapei n.° 36 - 1/20/2023

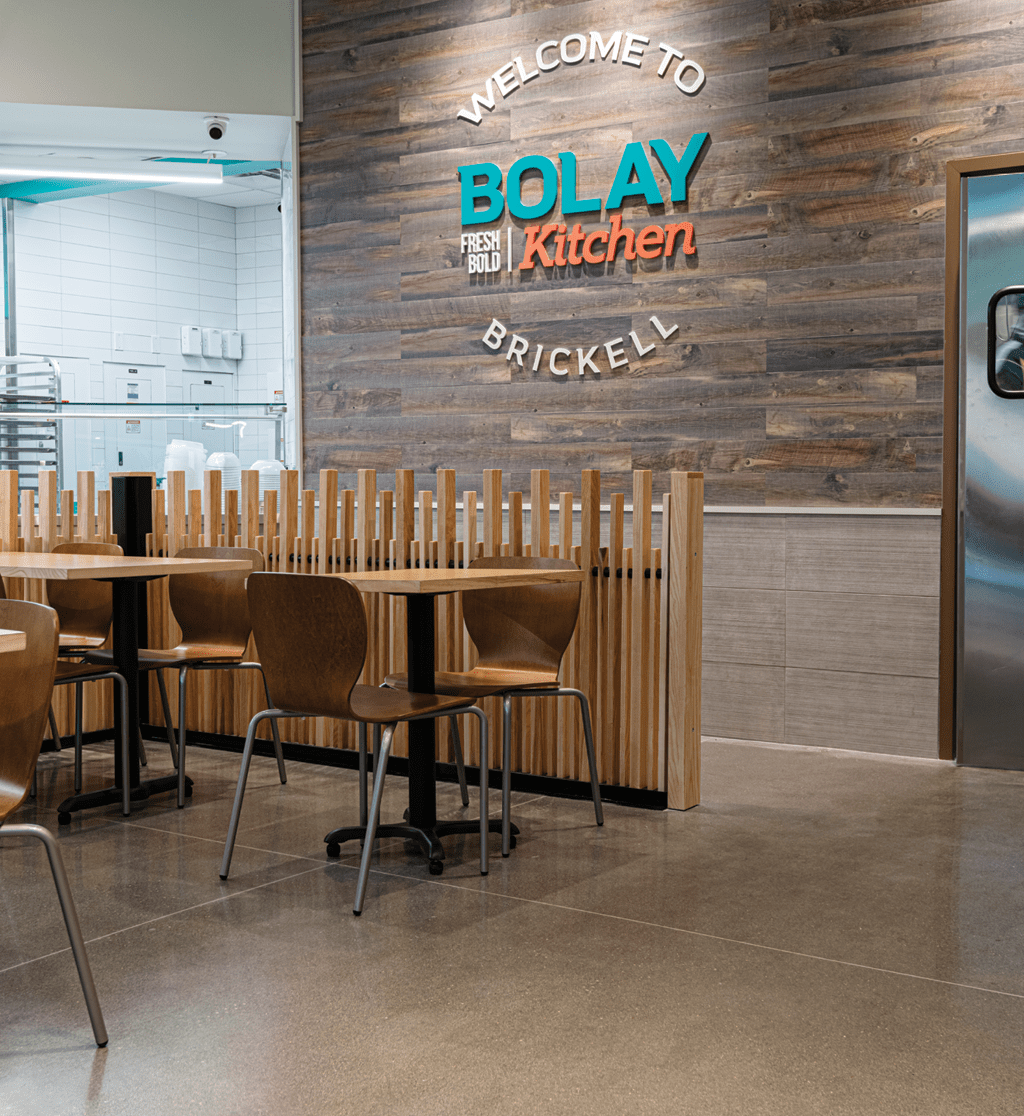

Bolay – the restaurant chain’s unique name combines the signature “bol” dish with the exclamation of excitement “olé!” to create the word “Bolay” – has gained in popularity since it was founded by a father-and-son duo in 2016. Chris Gannon, CEO and cofounder of Bolay (along with his father, Tim Gannon, who co-founded the popular Outback Steakhouse chain), wanted to do more than simply create a fast-food restaurant. Located in Florida, Georgia and Virginia, Bolay restaurants offer fresh and bold ingredients with eight custom spice blends that have been created by noted chefs.

Bolay is expanding: At the time of this publication, they had a chain of 25 restaurants in Florida, two in Virginia and one in Georgia, all of which are known for “promoting fresh ingredients, with amazing guest service.” The 1,500-square-foot (139-m2) restaurant located at 801 Brickell Avenue in Miami is one of the new locations and features the high-performance, ultra-modern-look floor that is a key component of their “immaculate environment.” For that reason, they called MAPEI and wanted to install our Ultratop Polished System.

This installation is an example of great multidisciplinary teamwork to achieve a common goal through the highest industry standards. The project lead was provided by MAPEI’s architectural team working with Bolay. Specifications were developed by working with MAPEI Architectural Rep Luis Roman, Business Development Leader Maurizio Luccarelli and local Concrete Restoration Specialist Carlos Hernandez.

The architectural plans called for a floor with a total thickness of 1-3/8" (3.5 cm). In conjunction with general contractor iConstructors, specifications were developed according to those conditions using MAPEI’s Ultratop Polished System.

The architects approved MAPEI’s self-leveling Planitop EL at 1" (2.5 cm) in thickness as an underlayment to raise the floor. Ultratop SP polishable cementitious topping, which provides a fine-aggregate exposed finish, was approved and used for the final 3/8" (10 mm) of the floor. Epoxy primer Primer SN and the stain-resisting, high-gloss Mapecrete Protector FF were also specified.

After surface preparation was started on the old concrete slab, significant damages were found. The topping installer CPC Concrete used MAPEI’s epoxy-injection crack-repair resin Epojet to properly repair all cracks. Then the slab was blasted to a concrete surface profile (CSP) of #3. The concrete slab was now ready for Primer SN, a two-component, filled, epoxy primer specifically designed to enhance adhesion of cementitious multilayer flooring. After the primer was installed, sand was hand-broadcast on top to the point of refusal.

After 24 hours, Planitop EL was poured onto the floor as an underlayment to raise the floor. Planitop EL is self-leveling, Portland-cement-based product used as an underlayment to raise the floor in cementitious topping systems. Then, 24 hours after the Planitop EL installation, the crew blasted the self-leveling underlayment to a CSP of #3. The prepared surface was properly primed with Primer SN, and sand was broadcast to refusal.

Once the crew had waited 24 hours, the cementitious topping Ultratop SP was poured for the final 3/8" (10 mm) thickness of the floor. Ultratop SP is engineered for fast-track resurfacing of horizontal wear surfaces. This, according to Luccarelli, “was used as a topping to provide a fine-aggregate exposed finish.” After another 24 hours, the crew began the process of dry-polishing the Ultratop SP using the proper equipment and tools. Mapecrete Hard LI lithium silicate densifier was used finishing the final steps of the polishing process with Mapecrete Protector FF as a final polish guard that is designed to increase the stain resistance of interior, polished or hard-troweled cementitious toppings.

It was a fast installation. The restaurant was able to install furniture within days and open on schedule. Plus, the beautiful polished floor can withstand the foot traffic, the scraping chairs and the sticky, acidic food spills that come with hungry diners. The next time you find yourself in Miami, stop by Bolay Brickell. And while you are looking up at the menu, be sure to look down at the floor. MAPEI and Bolay – both are cause to say “olé!”

TECHNICAL DATA

Bolay Brickell – Brickell Miami, FL, USA

Project category: Commercial

Year of construction: 2021

Year of MAPEI involvement: 2021

MAPEI coordinator: Carlos Hernandez

Project owner: Bolay

General contractor: iConstructors, LLC – Fort Lauderdale, FL

Installer contractor: CPC Concrete, LLC – Tampa, FL

Project size: 1,500 sq. ft. (139 m2)

Challenges: After starting the project, it was discovered that the floor was more corroded than previously thought. To address this, the crew used epoxy injection resin Epojet to repair the cracks. Primer SN two-component, filled, epoxy primer was installed to enhance adhesion of the cementitious and multilayer flooring. Self-leveling underlayment Planitop EL was installed to raise the floor. Ultratop SP polishable, self-leveling cementitious topping provided a fine-aggregate exposed finish for the final 3/8" (10 mm) of the floor. Mapecrete Hard LI was then added to the dry polishing process as a lithium densifier, and Mapecrete Protector FF was installed as a final polished guard to increase the stain resistance of MAPEI’s interior, polished concrete Ultratop Polished System.

MAPEI products: Epojet, Mapecrete Hard LI, Mapecrete Protector FF, Planitop EL, Primer SN, Ultratop SP

![Epojet [NA]](https://cdnmedia.mapei.com/images/librariesprovider10/products-images/4_3000367-epojet-13-5oz_b39f7a91217a4fa3ae561d2fcb520c45.png?sfvrsn=b9542e8e_0)