Browse by PRODUCT LINES

Browse by PRODUCT LINES

All product lines

All product lines

Search products

Search products

In the spotlight

In the spotlight

Questions and concerns are often raised when ceramic tile or stone is to be installed over a radiant-heating system. These concerns usually are regarding any detrimental effect that the heat from the radiant heating might have on the bond of the tile, approved substrates and when the system can be activated. Typically, the maximum heat from a radiant-heating system does not exceed 85°F (29°C); this level of heat would not affect installation systems and accessories that are designed for tile and stone.

The TCNA Handbook for Ceramic, Glass, and Stone Installations provides recommended minimum cure/dry times for individual substrates and products. Minimum cure times are not listed here due to the many combinations of systems in the TCNA Handbook, refer to the TCNA Handbook for specifics. At a brief glance, these individual substrates and products entail:

Substrate suitability

Adhesive suitability

Underlayments

Type of system

The handbook further recommends the following installation practices. Always follow manufacturer’s recommendations when installing product:

Substrate suitability

Adhesive suitability

Underlayments

Floor-warming systems

MAPEI has a full line of electric radiant-heating systems that are suitable for use under a variety of floor coverings. Whether you are looking to take the chill off a bathroom floor or heat an entire room, MAPEI’s Mapeheat has the solution you need.

Mapeheat Mat: Pre-wired floor-heating fabric; compact 1/8" (3 mm) profile for minimal floor buildup; even heat distribution, with no cold spots; easy installation; standard and custom mats available

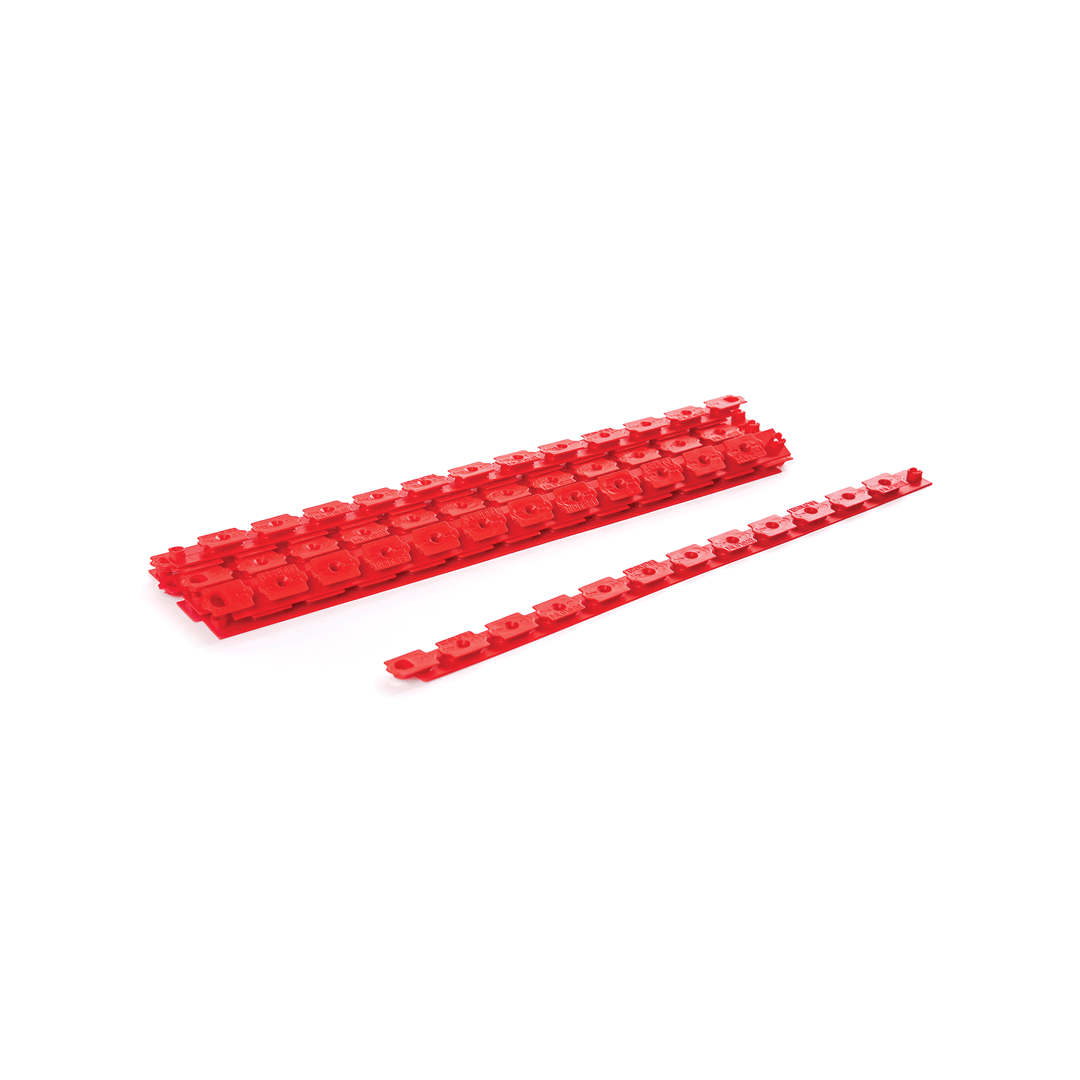

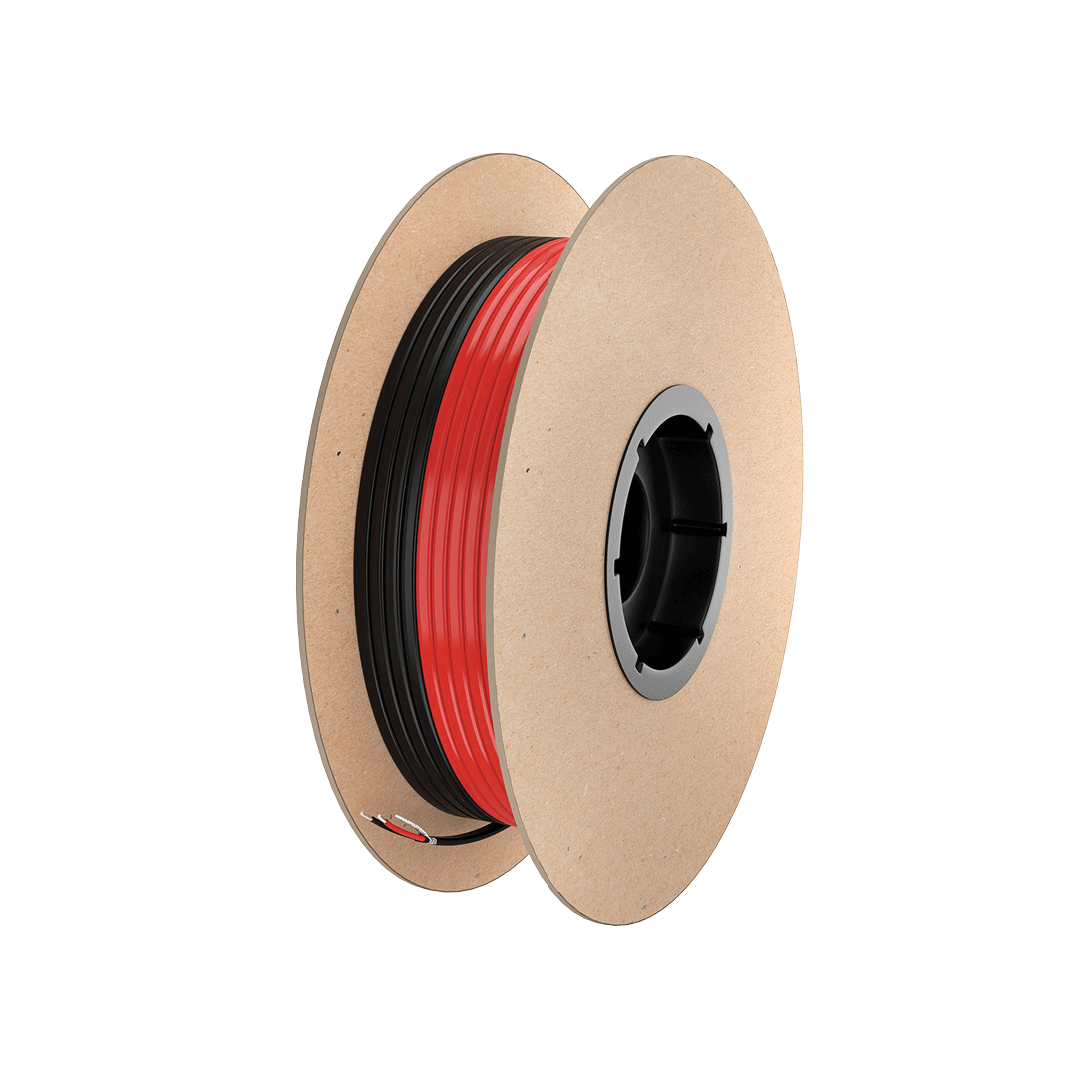

Mapeheat Cable: Suitable for wet environments, such as showers and steam rooms; for use with Mapeheat Membrane or Mapeheat Cable Guides

Mapeheat Membrane: Crack-isolation and waterproofing membrane; thin profile of less than 1/4" (6 mm); replaces plywood or cement board as tile underlayment

Mapeheat Mesh: Pre-wired, floor-heating mesh with self-adhering tape; can be configured on site to fit any room

Technical Services at 1-800-992-6273

Customer Service at 1-800-426-2734 (1-800-42-MAPEI)

Comments

Load more comments