Browse by PRODUCT LINES

Browse by PRODUCT LINES

All product lines

All product lines

Search products

Search products

In the spotlight

In the spotlight

Roadmap

for

Roadmap

for Concrete is far from being considered as a sustainable material, particularly due to the massive amounts of CO2 emissions associated with the production of Portland cement. Amongst the various levers in the hands of the cement industry to control greenhouse gas emissions, the industry has a number of innovative technologies that will assist in reducing its carbon footprint. These include carbon capture and reducing the clinker/cement ratio.

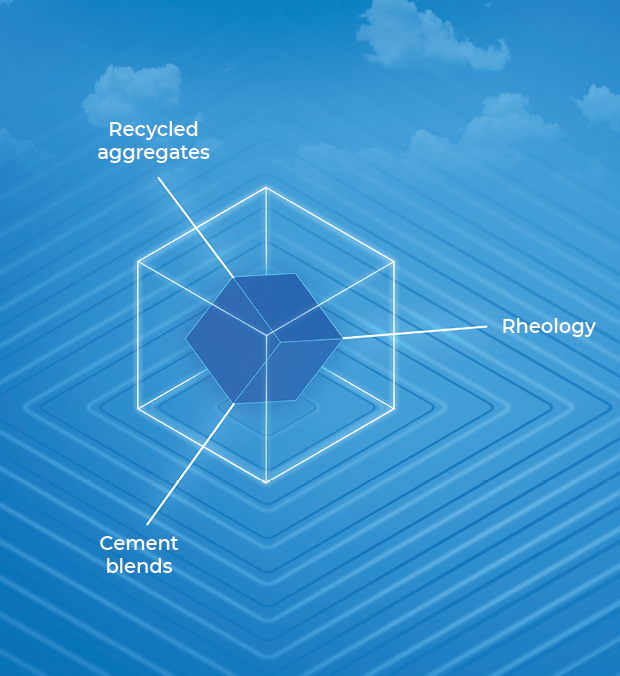

One such approach is the use of secondary cementitious materials or SCM (such as blast-furnace slag, fly ash and natural pozzolans) to partially replace clinker in the manufacture of cement. This is a fundamental part of the strategy to reduce CO2 emissions by 55% by the year 2030 and to achieve carbon neutrality by the year 2050.

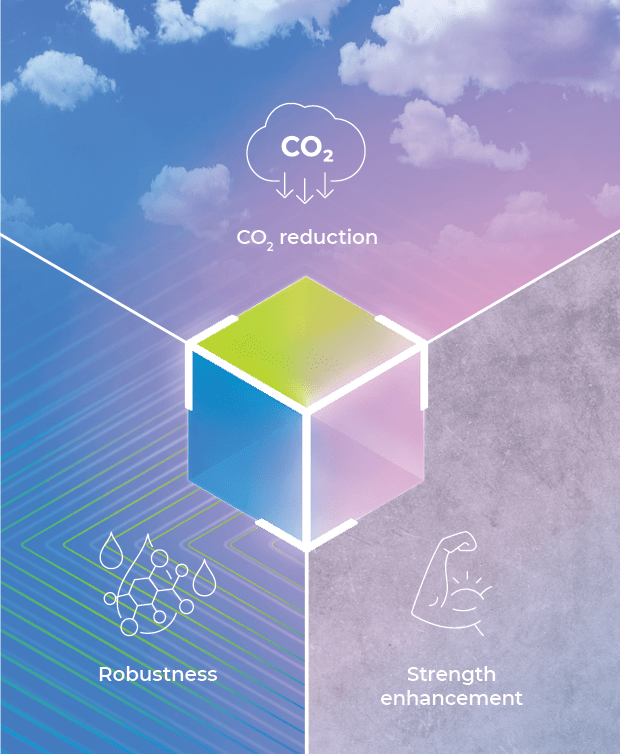

Future concrete will be produced using cement with lower clinker content. However, the use of recycled aggregates in concrete production presents several challenges for the concrete industry. Mixes generally will demand increased water content to achieve and maintain optimal rheological properties and the slower development of strength at both early and late stages.

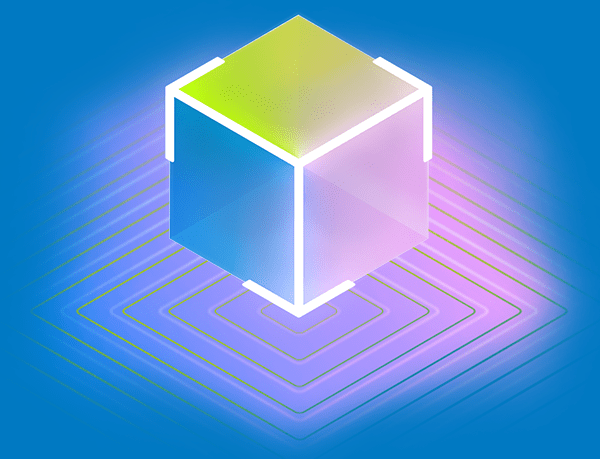

At MAPEI we are committed to improving the sustainability of the construction industry, while supporting our customers in this very dynamic environment. To this end, we have developed the CUBE system. This integrated approach helps the concrete industry in overcoming the difficulties of reduced clinker cements and aggregates of varying quality through the various phases: Production, placement and in situ. CUBE system actively helps the industry maintain its high standards while reducing the climatic impact.

This new concept of superplasticizers is specifically designed to face the challenges of the sustainable concrete.

Polymers designed to disperse a wide range of cementitious materials, including Type 1L and low-alkali cements

Special absorption inhibitors (RE-CON AGG technology) integrated into the formulations

Specific gradual-release polymers that guarantee low viscosity and extended workability without delaying set time

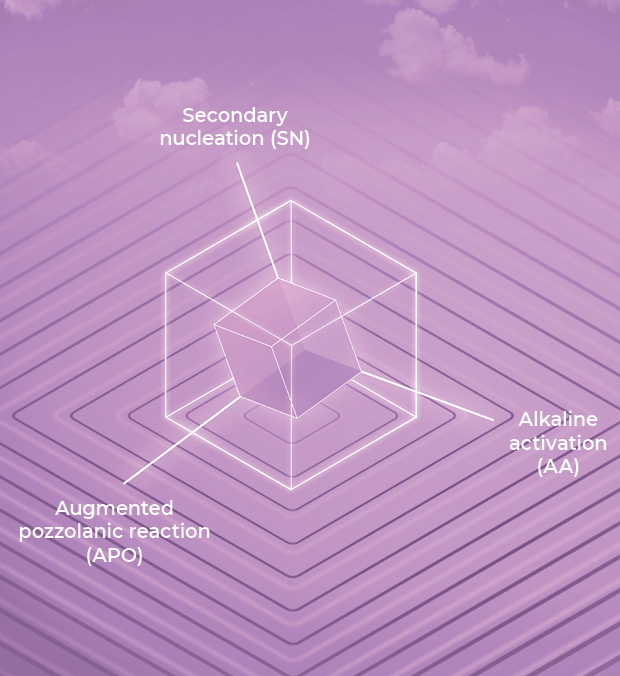

Thanks to the use of proprietary technology based on nano-compounds of silicate hydrates, our patent-pending CUBE system represents the fundamental cornerstones of the next generation of admixtures for the new cements with reduced clinker content.

The addition of nano-composite silicate hydrates produces hydration reactions more rapidly and diffusely in the cement paste.

The combination of nano-compounds of silicate hydrates incorporates set-balancing components and produces a more powerful pozzolanic reaction, thereby enabling faster development of strength after both short and long curing cycles.

The new blended cements have a smaller carbon footprint and combine the properties of Portland cement with the properties of alkaline activation materials. Development of the strength of blended cements is promoted by the alkaline activation of their components.

| PRODUCT FAMILY | |

|---|---|

| Mapecube 1 | Early strength enhancer for shorter curing times |

| Mapecube 4 | All-ages strength enhancer for fly ash or slag-Portland blends |

| Mapecube 60 | Strength enhancer with fluidifying effect for concrete with low CO2 emissions |

| Mapecube 60W | Strength enhancer with fluidifying effect for concrete with low CO2 emissions, especially suited to colder environments |

Technical Services at 1-800-992-6273

Customer Service at 1-800-426-2734 (1-800-42-MAPEI)