Browse by PRODUCT LINES

Browse by PRODUCT LINES

All product lines

All product lines

Search products

Search products

In the spotlight

In the spotlight

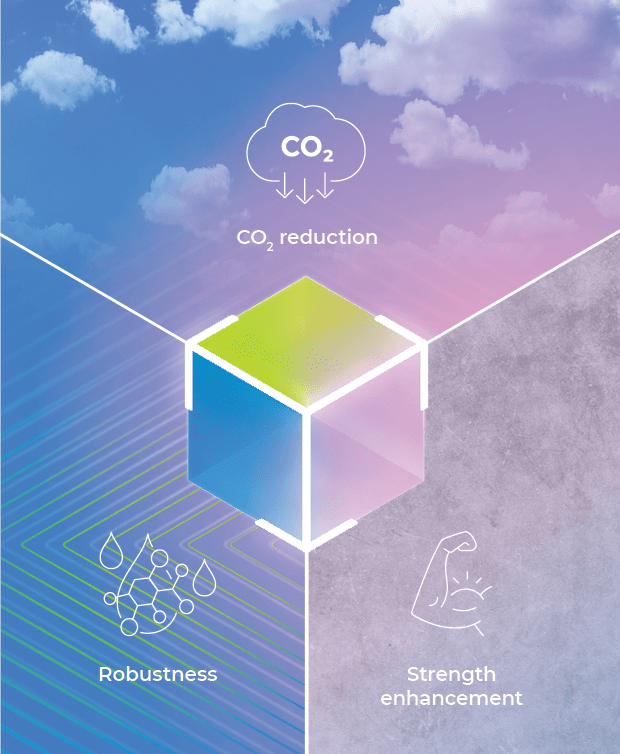

Deerfield Beach, Florida — MAPEI Corporation, a leading manufacturer of construction materials for the building industry, announces the debut of our CUBE system for concrete. The CUBE system is a portfolio of products that are designed to help reduce CO2 emissions from the production of concrete by optimizing the use of alternative binders and cement replacement materials in the production of ready-mix and precast concrete while maintaining the same hardened properties. The CUBE system consists of the following products:

Deerfield Beach, Florida — MAPEI Corporation, a leading manufacturer of construction materials for the building industry, announces the debut of our CUBE system for concrete. The CUBE system is a portfolio of products that are designed to help reduce CO2 emissions from the production of concrete by optimizing the use of alternative binders and cement replacement materials in the production of ready-mix and precast concrete while maintaining the same hardened properties. The CUBE system consists of the following products:

“MAPEI continually looks to improve our products and systems that, in turn, improve our built environment,” explained Cameron Bellman, MAPEI’s Corporate Concrete Admixtures Director. “The CUBE system is the Admixtures division’s latest answer to this challenge. The essence of this portfolio is to do more with less. With the CUBE system, producers of concrete can use increased volumes of alternative binders, while maintaining or even enhancing the concrete’s hardened properties. This offers a savings in C02 production and even in cost per cubic yard.”

Gianluca Bianchin, MAPEI’s Concrete Admixtures Region Manager for West Europe and the Corporate Product Manager Low Carbon Concrete Admixtures (LCCA), agreed with Bellman’s assessment. “Doing more with less is a very important factor for this system,” he stated. “We have increased the final strength of concrete 15% to 25% while reducing the required dosage, and we have increased the usage of recycled aggregates. Mapecube 60 and Mapecube 60W, for example, are suitable for use with all cements, have a high workability and retention, and require low cement dosage for excellent durability and strength. Mapecube 60W is designed to be used in cold climates and provides all the benefits of Mapecube 60 with the addition of a faster cure.”

This lower cement requirement is important for several reasons according to Gerald LaPier, MAPEI Corporation’s Sales Director of Concrete Admixtures and Cement Additives. He stated, “The lower dosage rate reduces the cement content required to meet predetermined strengths. This means that the products in the CUBE system reduce the amount of cement and cement by-products that are needed to produce concrete, while at the same time maintaining or exceeding the resulting concrete’s strength. It sounds counter-intuitive, but it is a true win-win situation. A reduction in cement content means a reduction in emissions and in costs, while the system’s advanced chemistry means an increase in strength. This system underscores MAPEI’s commitment to sustainability and to providing the best, most innovative products on the market.”

To learn more about MAPEI’s CUBE system, please visit online at https://www.mapei.com/us/en-us/products-and-solutions/in-the-spotlight/cube-system

About MAPEI

Founded in 1937 in Milan, MAPEI is now one of the world’s leading manufacturers of chemical products for the building industry and has contributed to the construction of some of the most important architectural and infrastructure works worldwide. With 100 subsidiaries operating in 57 countries and 86 manufacturing plants in 35 nations, MAPEI Group employs more than 11,000 staff worldwide. The foundation for the success of the company is specialization, internationalization, research & development, and sustainability.

Headquartered in Deerfield Beach (Florida), MAPEI North America consists of the subsidiaries MAPEI Corporation (for the USA), MAPEI Inc. (for Canada) and MAPEI Caribe (for Puerto Rico and other Caribbean islands), whose 28 facilities collectively have a workforce of about 1,800 employees. MAPEI facilities have been certified to ISO 9001 and ISO 14001 quality standards. An environmentally conscious manufacturer that reinvests 5% of its revenue into R&D, MAPEI offers training for architects, contractors, installers and distributors through the MAPEI Technical Institute. For more about MAPEI, visit www.mapei.com or call 1-800-42-MAPEI

Technical Services at 1-800-992-6273

Customer Service at 1-800-426-2734 (1-800-42-MAPEI)