Búsqueda por LÍNEAS DE PRODUCTOS

Búsqueda por LÍNEAS DE PRODUCTOS

Todas las líneas de productos

Todas las líneas de productos

Búsqueda de productos

Búsqueda de productos

En el foco

En el foco

De Realtà Mapei n.° 30 - 12/12/2022

Reprinted from Realtà MAPEI International magazine, Issue #72. This article is by Giorgio Ferrari and Amilcare Collina of Mapei S.p.A.’s Research & Development division.

Thirteen billion cubic meters of concrete are produced every year around the globe, the equivalent of around thirty billion tons or almost four tons per year for each inhabitant of the planet. This material owes its enormous success to its excellent characteristics and properties: Cost-effectiveness, the wide availability of raw materials, excellent mechanical properties and durability. Each and every day, in every corner of the planet, hundreds of thousands of trucks transport fresh concrete from mixing plants to building sites to be used in the construction of every possible type of building and infrastructure.

Not all the concrete that is produced, however, is actually used on site. A certain amount, from just a few hundred liters to several cubic meters, is returned to the mixing plant in its original state as what is known as “leftover” or returned concrete. For various reasons, the production of returned concrete is unavoidable and, as such, has to be considered as an integral part of the production process. According to estimates, returned concrete accounts for around 3% of the total amount produced, or around 900 million tons per year at a global level.

Only a fraction of all returned concrete may be reused as is in concrete works, while for the most part, due to the lack of a viable possibility of using it again and transforming it, it has to be disposed of. For this reason, returned concrete is by far the most abundant waste product at the concrete batching plants. Disposing of returned concrete in landfill sites has a heavy impact on the environment, which may be expressed in terms of “equivalent” CO2, the gas responsible for global warming. In numerical terms, one cubic meter of returned concrete sent for landfill is the equivalent of 267 kg of CO2, which, if multiplied by the amount of returned concrete produced annually in the world, amounts to almost 105 million tons of CO2, the same amount produced in one year by around 47 million medium-sized cars, more than the cars currently in use in Germany.

Today, with Re-Con Zero Evo, MAPEI’s product for more sustainable concrete, it is possible to recover and transform returned concrete, thereby going from a “linear” economic model, based on the production of waste, to a more “circular” economic model in which waste no longer exists but rather becomes a resource. A circular economy is a regenerative type of industrial system. It replaces the “end of life” concept with a concept of “restoration,” prevents the depletion and decline of natural resources, encourages the use of renewable energy, eliminates the use of toxic chemical substances that impede its reuse/return to the biosphere and aims at eliminating waste by improving the design of materials, products, systems and business models.

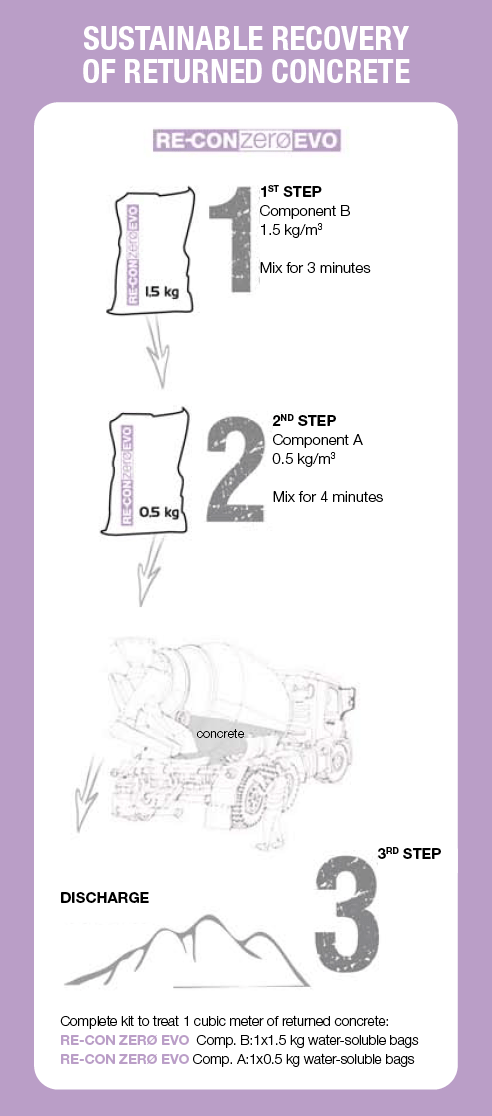

But how is it possible to transform concrete from waste material into a resource with Re-Con Zero Evo? When Re-Con Zero Evo is added to returned concrete in a mixer truck, or in any other suitable mixing system, in the space of just a few minutes the special additives contained in the product absorb any free water that is present, thereby “drying” the concrete. This transforms it into aggregates with a grain size distribution and mechanical characteristics that are perfectly suitable to be reused to make new concrete without generating any new waste – liquid or solid.

The advantages of this innovative product are clear: The production of aggregates from returned concrete enables the acquisition of natural aggregates to be reduced by a corresponding amount, which in turn limits the depletion of raw materials. The process also completely eliminates the use of landfill sites, which in turn further reduces the impact on the environment. With Re-Con Zero Evo, one cubic meter of returned concrete produces only 6.75 kg of CO2, almost 40 times less than when compared with disposing of it as landfill. Apart from these environmental benefits, there are also corresponding advantages associated with its use for the entire industrial system: A significant reduction in costs for production, the acquisition of raw materials and the disposal of waste.

Today, thanks to Re-Con Zero Evo, there is now the certainty that all returned concrete can be recovered and reused, by means of a process of industrial transformation based on the principles of a circular economy, to produce aggregates with all the technical and environmental requirements for its correct use in the production of concrete and in other civil engineering works.