Búsqueda por LÍNEAS DE PRODUCTOS

Búsqueda por LÍNEAS DE PRODUCTOS

Todas las líneas de productos

Todas las líneas de productos

Búsqueda de productos

Búsqueda de productos

En el foco

En el foco

De Realtà Mapei n.° 30 - 4/24/2020

Reprinted from Realtà MAPEI International magazine, Issue #72.

This question-and-answer session with David Sedan, Concrete Admixtures Technical Manager for MAPEI France, focuses on the international admixtures market.

Q: What is the definition of an admixture?

A: According to current standards (such as the French standard

NF EN934-2 and the European standard CE EN 934-2), “An admixture for concrete, mortar and slurry is a material added to a concrete or mortar mix during the preparation phase at a rate of up to 5% by weight of the cement to modify the properties of the mix in the wet and/or hardened state.” In simple terms, an admixture is an “ingredient” added to the other components of a mix in order to modify and control certain final characteristics of concrete or mortar.

Q: What are the various families of admixtures and how many are there?

A: There are various families of admixtures and they are defined on the basis of their primary function, although they may also have one or more secondary functions. There are seven main families divided into three groups:

• Admixtures used to modify the rheological properties of concrete

o Plasticizers and water-reducing agents

o Superplasticizers and highly effective water-reducing agents

• Admixtures to modify setting and hardening rates

o Set accelerators

o Hardening accelerators

o Set retarders

o Set retarders

• Other categories of admixtures

o Water-repellant admixtures

o Air-entraining agents

Q: Are there any other products that can modify the properties of concrete?

A: Actually, there are other products – also considered to be admixtures, according to NF EN 934-2 standard – that can modify the intrinsic or aesthetic properties of concrete.

Among these products, we could mention structural fibers that are used to improve compressive or flexural strength, microfibers as a substitute for anti-cracking mesh, viscosity-modifying admixtures, colloids that are used for concrete to be cast under water and/or concrete subjected to segregation during placing, shrinkage-reducing agents, foaming agents, and pigments for concrete.

And let’s not forget admixtures used for underground work, such as liquid retarders with a stabilizing and plasticizing effect for cementitious injection systems, as well as accelerators for shotcrete.

Q: Can you give us a few examples of how admixtures are used in industry?

A: Let’s use the examples of deep foundations or pre-cast concrete walls, for which it is necessary to work in operating conditions for more than six hours with a high reduction of water. In this case, it is very important to use one of the latest generation of plasticizers, or even a synergic combination between a superplasticizer and a set retarder. For instance, DYNAMON EASY 70 and DYNAMON EASY 74 allow you to achieve excellent results with just a single admixture, depending on the type of cement used.

Q: What does the future hold for the development of admixtures?

A: We are concentrating more and more on the development of admixtures that allow you to formulate concrete using materials normally defined as difficult, such as sand with high clay or even recycled content. In fact, the scarcity of raw materials is a problem that lies at the heart of research into new admixtures because the materials used to formulate new concrete are, for obvious economic reasons, often sourced locally. This is why research conducted in the lab is looking into the existence and development of alternative mineral admixtures that can be – at least partially – used as a substitute for cement, blast furnace slag, fly ash (which is a by-product of the combustion of coal in power stations) or metakaolin (which is obtained by grinding kaolin and firing it at 750oC).

Q: Can you explain how admixtures work?

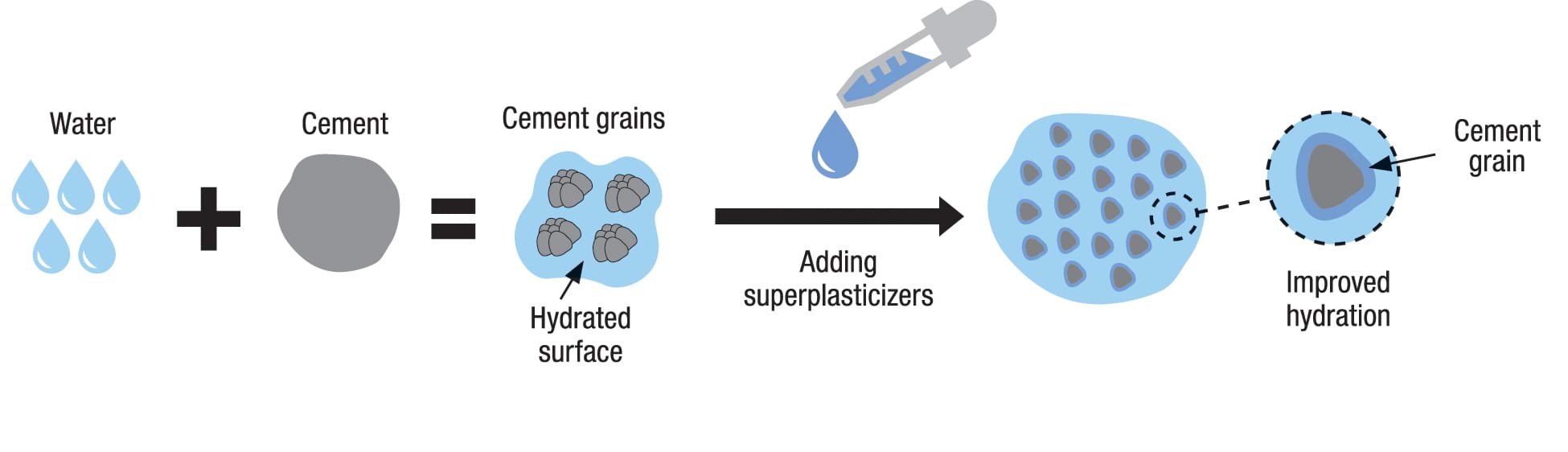

A: Plasticizers and superplasticizers allow the amount of water in concrete to be drastically reduced (water-reducing agents) or considerably improve the consistency of concrete without altering the amount of water or produce these two effects at the same time. Superplasticizers reduce water by a much higher amount than plasticizers and have, therefore, a much more pronounced effect.

|

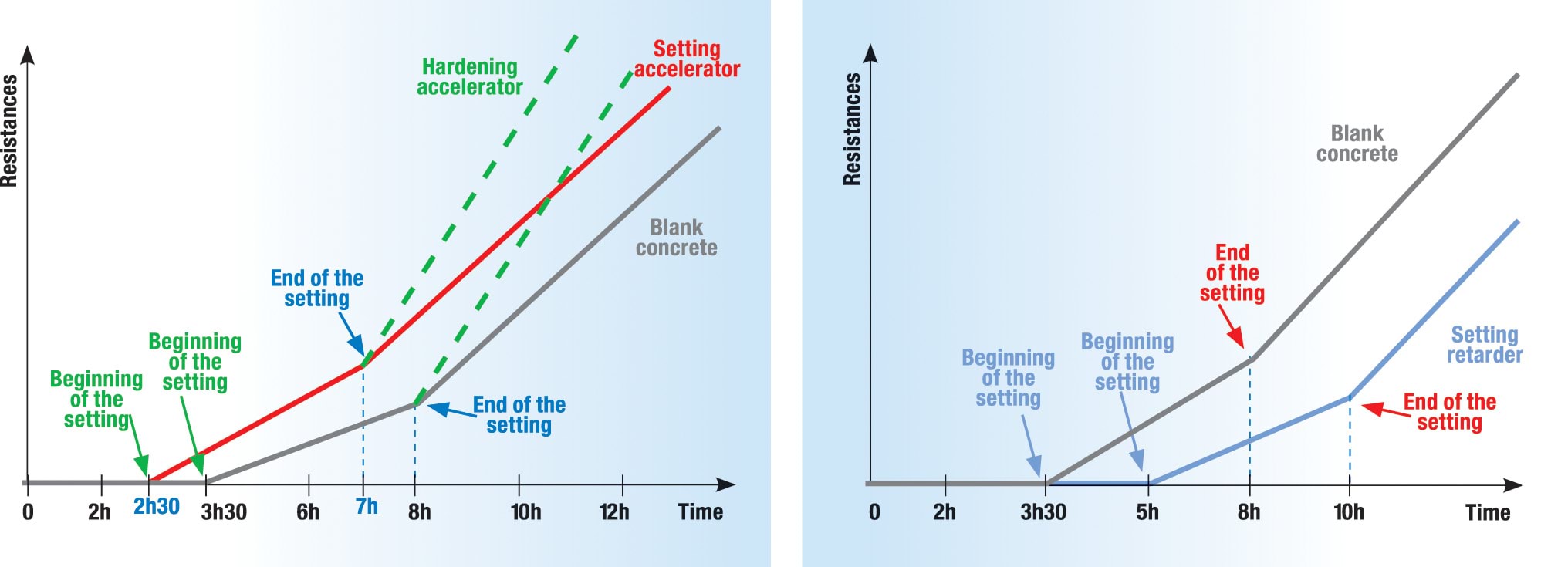

Set accelerators act as catalysts in initial cement hydration reactions, especially at low temperatures, and accelerate the concrete setting (see the graph below, at left). Hardening accelerators improve the early compressive strengths, with or without modifying the setting times. Set retarders delay the moment at which concrete starts to set (see the graph below, at right).

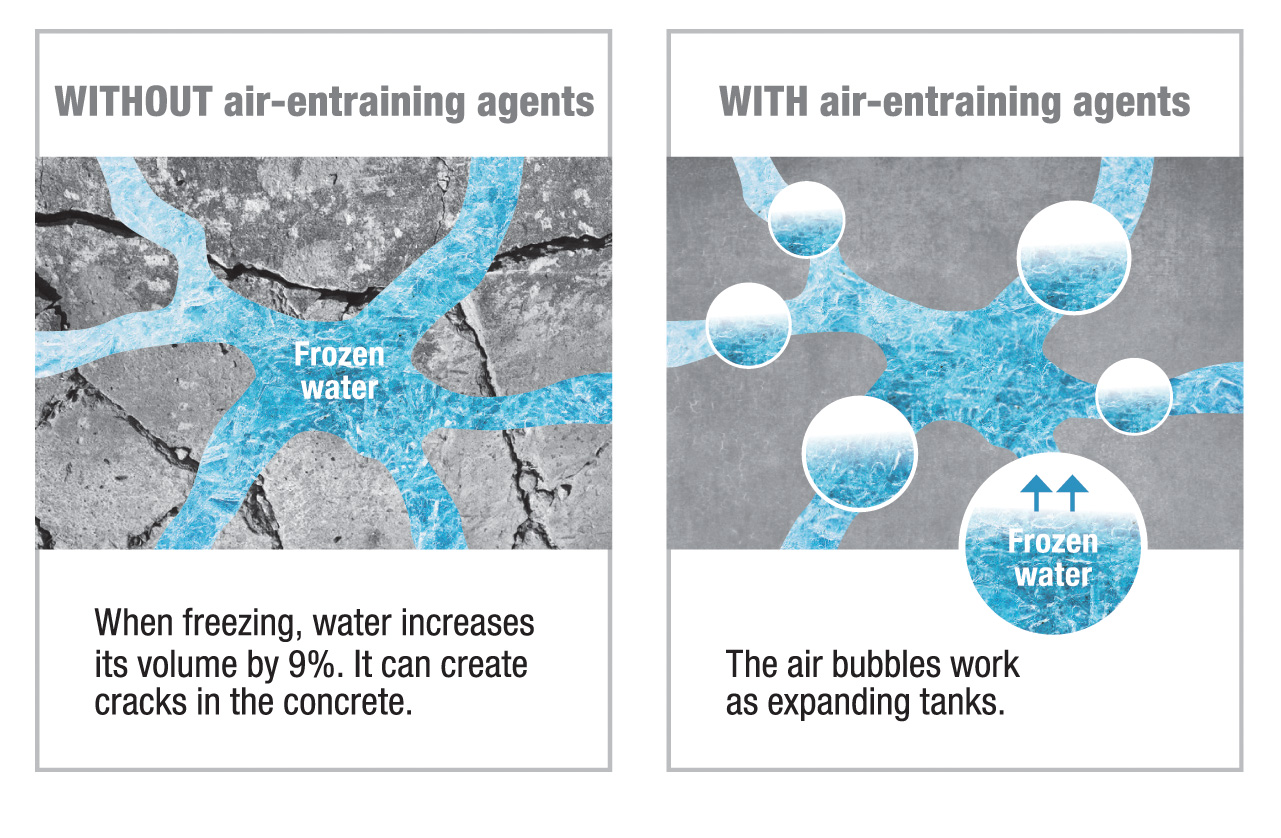

Air-entraining agents create a stable network of microscopic air bubbles in concrete, which improves the durability of concrete exposed to freeze/thaw cycles and the action of de-icing salts.

And lastly, water-repellent admixtures react to form water-repelling particles. These reduce the capillary action within concrete and can reduce the infiltration of water under pressure.