Sustainability

N° 30 - 12/9/2022

Create sustainable concrete with Re-Con Zero Evo

Create sustainable concrete with Re-Con Zero Evo

Browse by PRODUCT LINES

Browse by PRODUCT LINES

All product lines

All product lines

Search products

Search products

In the spotlight

In the spotlight

MAPEI’s Re-Con line helps concrete producers to move toward a more circular and effective production model by offering cost-effective and sustainable concrete solutions. Under the four key concepts of Reclaim, Clean, Recycle and Reduce CO2, substantial savings in waste-handling costs can be made by transforming returned concrete and truck-washing slurry into valuable material. The Re-Con line also offers products that enhance circularity of material flows by reducing the need for high-cost, virgin, raw materials... mitigating the problems of using recycled concrete, manufactured sand or clay-contaminated sand in new concrete.

This presentation focuses on the topic of reclaiming returned concrete and turning it into recyclable aggregates with the help of…

MAPEI’s Re-Con Zero Evo is the innovative solution that reclaims returned concrete and turns it into resellable aggregate or…

This two-component system consists of a superabsorbent polymer and a hardener. It transforms fresh returned concrete into a granular material by chemically binding the free water (Part A) and by stabilizing and accelerating the process (Part B).

70% less cementitious waste in every truck washout

Re-Con dry washing utilizes the absorption capability of the Re-Con Zero Evo US aggregates to clean trucks of cementitious waste that is otherwise washed out. Using the Re-Con dry-washing process followed by a light wash with

water will greatly reduce the truck-washout solids that lead to a high pH and increased pollution risk of heavy metals such as hexavalent chromium. With Re-Con dry washing, the root cause of truck-washout pollution is removed by transforming

waste into recycled aggregates in a repeatable process.

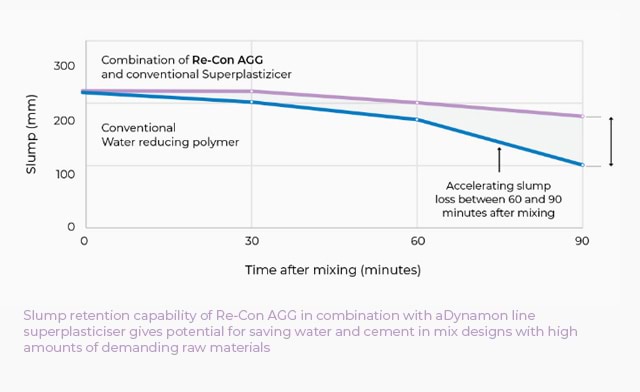

The absorption-mitigating properties of the Re-Con AGG technology enable concrete producers to start using sand, aggregate or binders (all with high water demands) without having to increase the water or water-reducing admixtures in their mix designs. Examples of applications are:

Re-Con AGG absorption-blocking technology partly makes mixing water and water-reducing admixtures available in the cement paste instead of being absorbed by the aggregates or binders. Finishability, water/cement ratio and cement consumption can be kept constant even at major changes to aggregate or binder properties.

Sustainability

N° 30 - 12/9/2022

Create sustainable concrete with Re-Con Zero Evo

Create sustainable concrete with Re-Con Zero Evo

Sustainability Research Product Spotlight

N° 30 - 1/20/2020

This question-and-answer session with David Sedan, Concrete Admixtures Technical Manager for MAPEI France, focuses on the international admixtures market.

This question-and-answer session with David Sedan, Concrete Admixtures Technical Manager for MAPEI France, focuses on the international admixtures market.