The presence of dirt and contamination on the substrate due to improper cleaning before tile installation can compromise good adhesion. Likewise, for the back of tiles. Other factors such as cracks in substrates or premature loading on substrates that are not fully cured can also result in adhesion issues.

Prevention: Ensure that the substrate is properly cleaned and prepared. The substrate must be free of dust, dirt of any deleterious material that will impede good adhesion. As for the back of tile, use a damp sponge to remove dust and dirt deposits before tile installation.

Weak adhesion can be due to insufficient adhesive coverage. Gaps and air voids in the adhesive bed could lead to debonding of tiles as well as tiles being fractured when hit by falling objects or subject to impact and vibration.

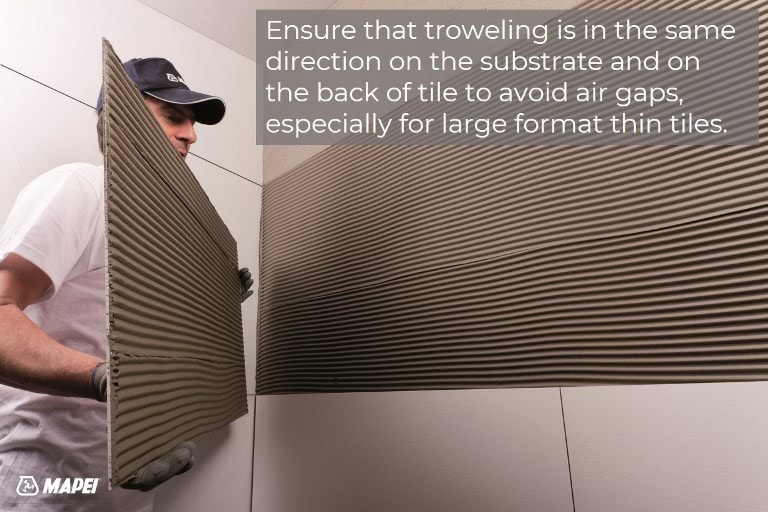

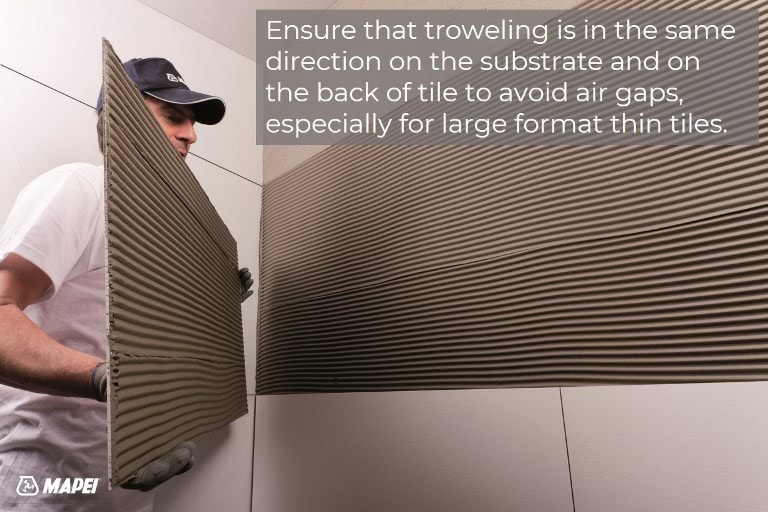

Prevention: Apply sufficient adhesive for coverage and contact between substrate and the back of tile. Lay tile into the adhesive with firm pressure to ensure trowel ribs collapse to good compaction and rid of air voids. In particular for large thin tiles, one directional troweling is recommended (not the multi-directional troweling) so as to ensure that the trowel ribs compress in one direction to avoid air gaps between the ribs.

Another situation of poor adhesion and contact is when the trowel ribs in the adhesive bed are not pressed down to full compaction. When tiles are placed onto the adhesive which has not been fully compressed to compaction, the contact is superficial and there will also be air gaps and voids in the installation.

Prevention: To ensure proper bonding of the tiles and substrate, the workman should press down the tile firmly using a rubber mallet to tap on the tile to eliminate trapped air gaps after laying. Proper bonding between the tile and adhesive material behind the tile may reduce the stress concentration.

About Mapei:

Founded in Milan since 1937, Mapei is today a world leading producer of adhesives and complementary products for the laying of all types of floor, wall and coating materials. Mapei’s specialty lies in products for ceramics and stone materials, among other product lines. Mapei’s tile adhesives are certified according to international standards and are SGBC certified in Singapore. Experience proven by numerous notable projects worldwide.

The presence of dirt and contamination on the substrate due to improper cleaning before tile installation can compromise good adhesion. Likewise, for the back of tiles. Other factors such as cracks in substrates or premature loading on substrates that are not fully cured can also result in adhesion issues.

Prevention: Ensure that the substrate is properly cleaned and prepared. The substrate must be free of dust, dirt of any deleterious material that will impede good adhesion. As for the back of tile, use a damp sponge to remove dust and dirt deposits before tile installation.

Weak adhesion can be due to insufficient adhesive coverage. Gaps and air voids in the adhesive bed could lead to debonding of tiles as well as tiles being fractured when hit by falling objects or subject to impact and vibration.

Prevention: Apply sufficient adhesive for coverage and contact between substrate and the back of tile. Lay tile into the adhesive with firm pressure to ensure trowel ribs collapse to good compaction and rid of air voids. In particular for large thin tiles, one directional troweling is recommended (not the multi-directional troweling) so as to ensure that the trowel ribs compress in one direction to avoid air gaps between the ribs.

Another situation of poor adhesion and contact is when the trowel ribs in the adhesive bed are not pressed down to full compaction. When tiles are placed onto the adhesive which has not been fully compressed to compaction, the contact is superficial and there will also be air gaps and voids in the installation.

Prevention: To ensure proper bonding of the tiles and substrate, the workman should press down the tile firmly using a rubber mallet to tap on the tile to eliminate trapped air gaps after laying. Proper bonding between the tile and adhesive material behind the tile may reduce the stress concentration.

About Mapei:

Founded in Milan since 1937, Mapei is today a world leading producer of adhesives and complementary products for the laying of all types of floor, wall and coating materials. Mapei’s specialty lies in products for ceramics and stone materials, among other product lines. Mapei’s tile adhesives are certified according to international standards and are SGBC certified in Singapore. Experience proven by numerous notable projects worldwide.