Have you ever noticed white deposits on the wall and floor surfaces of your tile or stone installations? This white residue is called efflorescence.

Efflorescence is a natural occurrence in Portland cement applications. All Portland-cement-based matrices (e.g. concrete sections, cement renders and screeds) contain calcium hydroxide (also known as hydrated lime), a soluble by-product of the cement hydration process. This is the compound that contributes to the high alkalinity of fresh concrete.

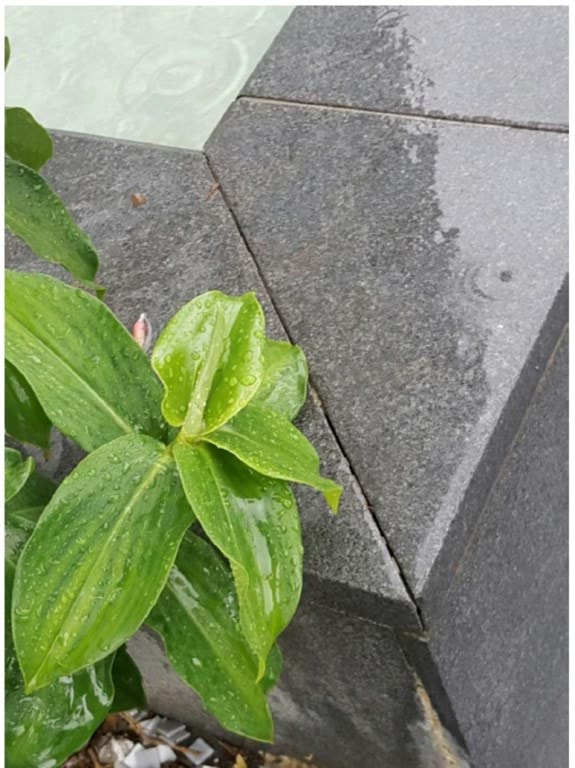

Under wet conditions, water penetrates weaknesses in the cement matrix (e.g. cracks, voids, high porosity, joints, etc.) which then dissolve and leach out the calcium hydroxide when dry conditions return. These are deposited on the surface and, on exposure to the atmosphere, they react with carbon dioxide to form calcium carbonate, a practically-insoluble, white crystalline salt. These are the unsightly efflorescence deposits we see on walls, facades and floors, mostly in exterior environments.

We can see from the above that three conditions are necessary for the occurrence of efflorescence:

i. Substrates with “efflorescence potential” i.e. containing calcium hydroxide and soluble

salts.

ii. Exposure of the substrates to wetting and drying cycles.

iii. Weaknesses which allow the passage of water into and out of these substrates.

The measures for controlling and minimising the occurrence of efflorescence lie in examining the three conditions and identifying good practices which can be adopted for eliminating one or more of these conditions. These can then be summarised as a list of good practice do’s for tile and stone installations.

List of Do’s

January 6, 2021. 3:44 AM

December 18, 2020. 2:12 AM