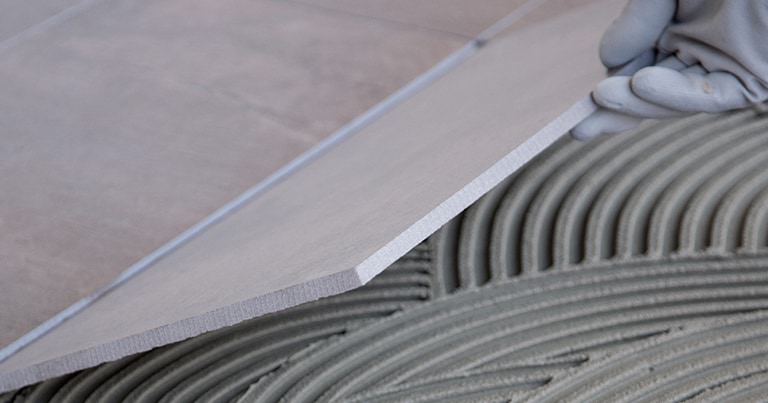

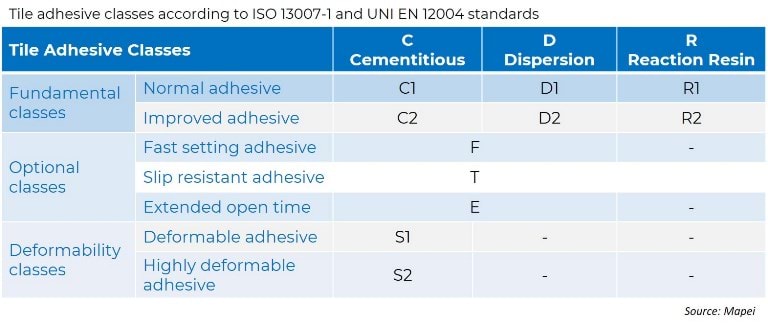

When choosing the most appropriate installation system, a good knowledge of the materials to be installed is essential. Installing tiles with adhesives by the thin-bed method shall meet specific requirements defined by European Standards EN 12004 and ISO 13007-1. These standards allow tile adhesives to be classified according to a clearly defined harmonized system that helps to identify their main characteristics, as a result, acts as a guide when choosing which system to adopt. Let’s take a look at what they are:

Adhesives are classified according to their chemical composition:

C – Cementitious adhesive

D – Dispersion adhesive

R – Reaction-resin adhesive

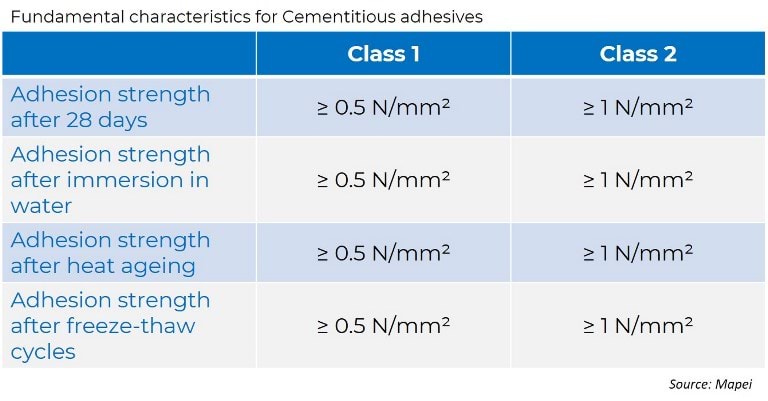

Cementitious adhesives are classified into different classes according to their adhesion properties and deformability. Tensile adhesion strength is tested under various curing conditions and, depending on the results obtained, it can be classified under Class 1 (C1 – normal adhesive) or Class 2 (C2 – improved adhesive).

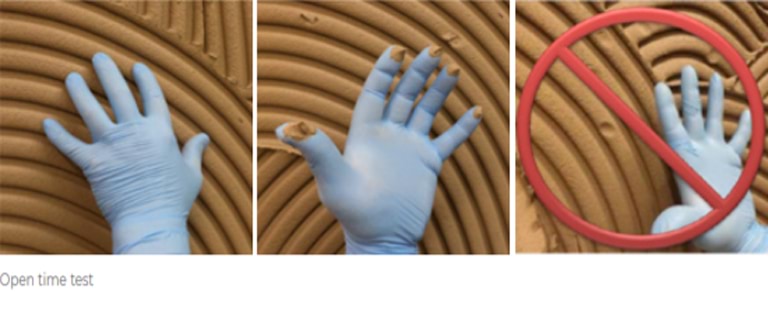

All C1 and C2 cementitious adhesives must meet the fundamental characteristics of : (i) Tensile adhesion strength of ≥ 0.5 N/mm² for C1 and ≥ 1.0 N/mm² for C2, (ii) Open time of not less than 20 minutes with tensile adhesion strength of ≥ 0.5 N/mm². Open time refers to the maximum interval after application at which tiles can be embedded in the applied adhesive and meet the specified tensile adhesion strength requirement. For fast-setting cementitious adhesives, the open time shall be not less than 10 minutes.

The table below shows the tensile strength criteria against each test condition for Class 1 and Class 2 cementitious adhesives:

Apart from the fundamental characteristics mentioned above, other optional classes may be added to indicate additional properties of an adhesive:

F: fast-setting/drying

T: No vertical slip

E: Extended open time

S: Special Deformable characteristic for cementitious adhesives only

Fast-setting adhesives, denoted by F, has rapid hydration properties for quick curing. This is typically used in works which require a fast turnaround time.

No vertical slip denoted by T, refers to the downward movement of tile applied to combed adhesive on vertical or inclined surface not exceeding 0.5mm.

Extended open time denoted by E, means the adhesive’s open time at no less than 30 minutes must meet the requirement of tensile adhesion strength of ≥ 0.5 N/mm².

Deformability is denoted by S, refers to the capacity of a hardened adhesive to be deformed by stresses between the tile and the fixing surface without loss of adhesion. Deformability of a cementitious adhesive is determined in a flexural test by measuring the deflection of the specimen.

Deformability is further classified into two classes: S1 – deformable and S2 – highly deformable. Adhesives that are able to meet the deformability range of between 2.5 and 5 mm are classified S1, adhesives that have a deformation of ≥ 5 mm are classified S2. Deformability test shows how flexible the adhesive is. Flexibility in adhesives will improve resistance to impact, environmental stresses caused by temperature and moisture cycles and thermal expansion and contraction in substrates.

Dispersion adhesives are also sub-divided into different classes according to the results obtained during the adhesion strength tests: they are classified as D1 (normal adhesive) for values ≥1 N/mm² after dry and heat ageing. The open time requirement for Dispersion adhesives shall be not less than 20 minutes with tensile adhesion strength of ≥0.5 N/mm2. For improved adhesive of class D2 adhesives, the additional characteristic of shear adhesion strength after 21 days’ air cure and 7 days’ water immersion shall be ≥0.5N/mm2 as well as shear adhesion strength of ≥1 N/mm² at elevated temperature.

Reactive adhesives are classified R1 when they meet the shear adhesion strength requirement of 2 N/mm² after dry curing and immersion in water. The improved R2 adhesive has the additional characteristic of shear adhesion strength after thermal shock of at least 2 N/mm². The open time for all reactive adhesives must be at least 20 minutes.

_____

About Mapei:

Founded in Milan since 1937, Mapei is today a world leading producer of adhesives and complementary products for the laying of all types of floor, wall and coating materials. Mapei’s specialty lies in products for ceramics and stone materials, among other product lines. Mapei’s adhesives for tiles and stones are certified according to international standards and are SGBC certified. Experience proven by numerous notable projects worldwide.