Slim tiles and large format tiles, as defined by UNI 11493-1, are as follows:

• Slim tiles: up to 5mm thick

• Large format tiles: having one side more than 60cm long

The particularly large format and extremely low absorption rate, typical characteristics of porcelain, means that it is very important to identify the most suitable installation method for this type of tile with extreme care and precision. As with any floor and wall finishing, the durability and functionality of slim porcelain is highly dependent on precise design parameters, appropriate substrate preparation and correct installation methods using adhesives, grouting mortars and joint sealants chosen according to the type of finishing material and its area of use.

Large format tiles may be installed on all substrates normally used in the building industry such as concrete, cementitious and anhydrite screeds, old ceramic and stone floors, metal, cement-based and gypsum-based render, plasterboard and so on.

The suitability of a substrate must be checked beforehand. As specified by current standards, substrates must always be:

Chapter 2: Choosing the Right Adhesive

When installing large format tiles, the most appropriate adhesive must be chosen in order to ensure they remain perfectly bonded over the years, prevent deformation in the tiles and ensure maximum reliability wherever they are installed. It depends on the following factors:

Type of tiles to be installed

It is necessary to take into consideration that the almost zero absorption rate of porcelain, along with the inclusion of strengthening mesh where prescribed, imposes the use of class C2 adhesives according to EN 12004 standards.

Dimensions of the tiles

For medium formats, it is recommended to use deformable adhesives from Class S1 according to EN 12004.

For large formats, it is strongly recommended to use highly deformable products from class S2 according to EN 12004.

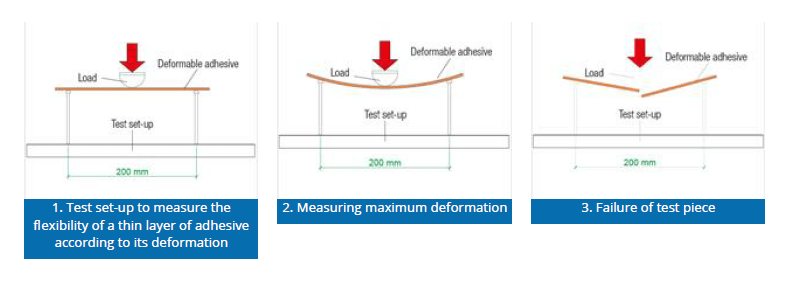

The deformability of adhesive is determined through flexural tests (the method described in EN 12004 – ISO 13307) which measures transversal deformation. A sample of adhesive is subjected to a load test as shown in diagrams 1 to 3 below. To achieve class S1, the deformability of the sample must be at least 2.5mm and for class S2, it must be at least 5mm.

Area of use and surrounding conditions

When working in hot climates, it is recommended to use class “E” adhesives (with extended open time) according to EN 12004. In all cases, tiles must be installed while the adhesive is still wet, or within its “open time”, in order to ensure sufficient transfer of adhesive onto the back of the tile.