For waterproofing applications…

Therefore, ways must be found to either (i) minimize these stress build-ups, or (ii) reinforce the waterproofing membrane where these discontinuities occur. Examples:

(i) Eliminate sharp bends at internal corners by providing 25 mm x 25 mm angle fillets to reduce stress concentrations. This is typically done with a latex-admixed, cement/sand mortar which must be allowed to cure before application of the waterproofing membrane. MAPEI recommends shrinkage-controlled, fibre-reinforced patching mortar, MAPEGROUT 218 for this purpose. Easy to use with a single mixing with water that is available in 5kg and 25 kg pack. For information on this product, please check https://bit.ly/34WUesf

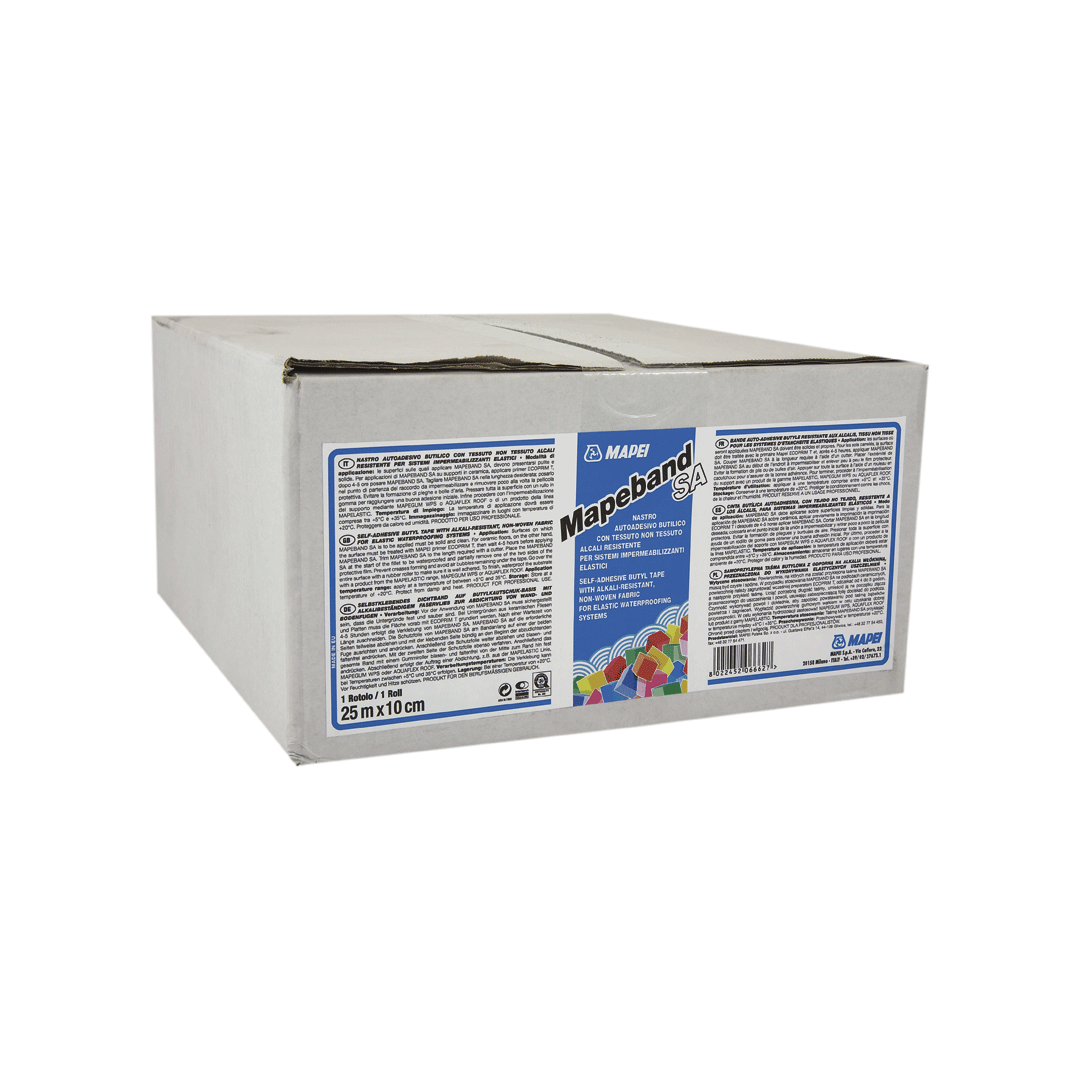

(ii) Reinforce the corner with an alkali-resistant, elastic, and waterproof band which has the robust physical properties for handling the increased stresses. MAPEI provides different types of bands for this application. They adhered to the different types of waterproofing materials and easy to install by overlapping this material in-between the joints of the wall and floor as well as on the edges. For more information, please check our range of Mapeband here: https://www.mapei.com/my/en/home-page#/search?text=mapeband&menu=Products

External corners are ground smooth to a radius of at least 20mm prior to application of waterproofing membranes.

Other surface preparations which are necessary prior to application of waterproofing membranes in order to avoid stress concentrations include filling of cracks and holes, and grinding flat all protuberances.

(Reference must be made to the manufacturer’s technical data sheet for instructions on use of particular products.)