Why are alumina cements produced by Górka so important for Mapei?

Focus on the benefits for Mapei products deriving from Górka's alumina cements.

Focus on the benefits for Mapei products deriving from Górka's alumina cements.

High alumina cements produced by Górka, both in the grey version (G40, which contains at least 40% aluminium oxide) and in the white version (with 70% aluminium oxide content), are now used in many of Mapei’s formulations.

The most significant effect exploited when used in formulas based on mixtures of Portland cement and alumina cement is the significant reduction in the setting time of mixes, which means it becomes possible to produce rapid-setting products, whereas products containing only Portland cement have much longer setting times. This rapid-set property is represented on packaging and data sheets for Mapei products by the “Fast Track” logo, which is precisely one of the effects that can be obtained by using alumina cement technology.

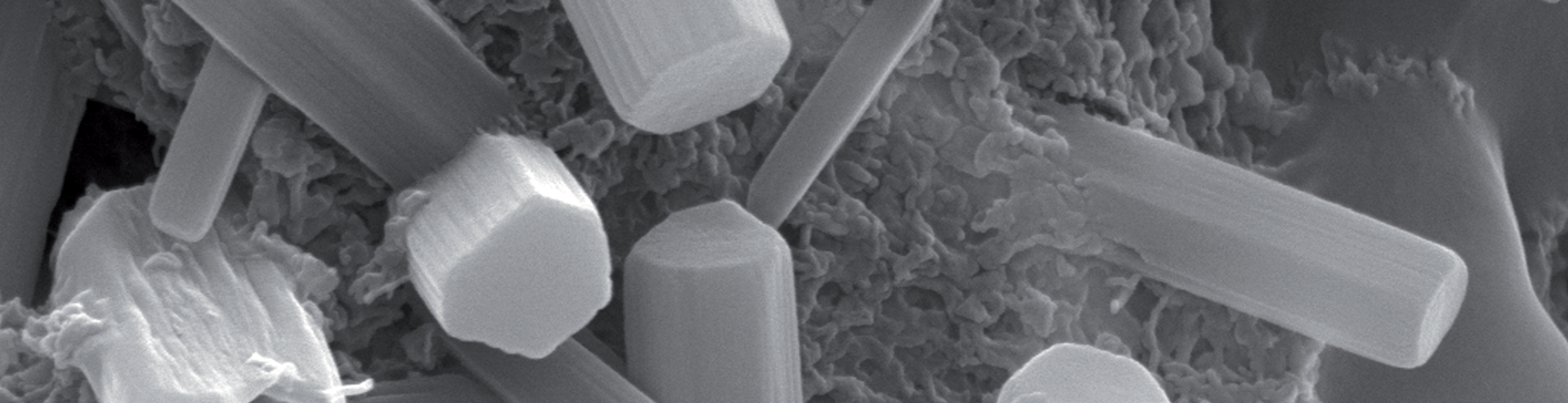

Very often, calcium sulphate is added to the Portland cement/alumina cement mix in order to obtain, by hydration, a species called ettringite, the properties of which are used to obtain products with special and unique properties.

The first example of applications using Górka alumina cement technology are F class rapid-setting cementitious adhesives, which allow fast accessibility of ceramic tiles installation. Moreover, tile adhesives that make proper use of the aluminate cement technology can quickly harden also in external applications at low temperatures.

This, however, is not the only noteworthy characteristic of rapid-setting adhesives, for which the formation of ettringite, an element that captures 32 molecules of water, is also important: 47% of the weight of ettringite is given by the weight of the water it captures, which is 50% more than the amount captured during the hydration process of Portland cement. This “water crystallisation” process is very important when installing natural stone, which is often highly sensitive to moisture and easily stained, preventing particularly unsightly aesthetic effects appearing in the stone, a common phenomenon when the wrong product is used. Adhesives developed specifically for installing natural stones sensitive to water, such as GRANIRAPID and ELASTORAPID, exploit the chemical mechanism described above in order to guarantee a product that is immune to the problem of staining.

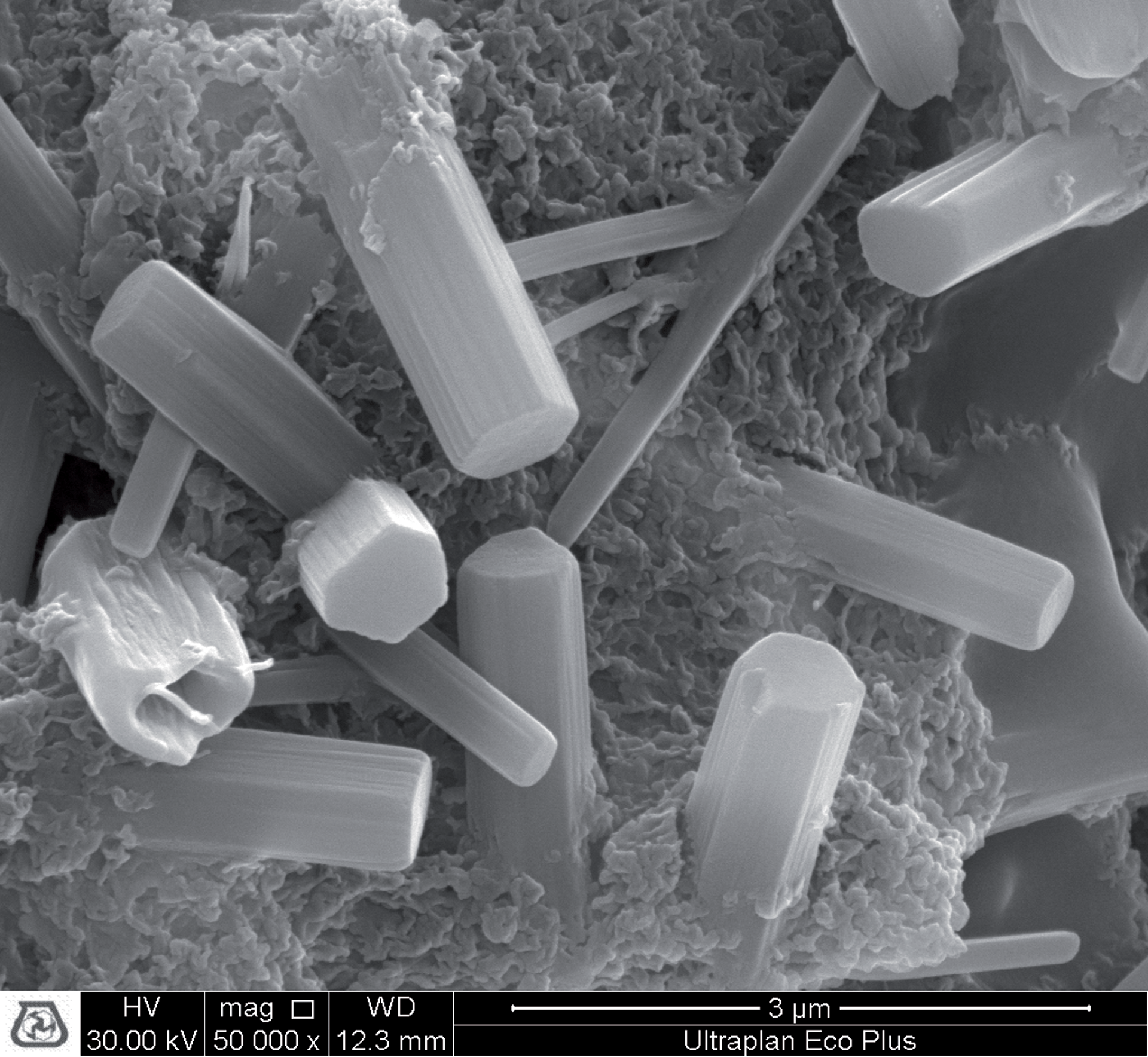

Alumina cement-based technology is also used for self-levelling products, particularly those from the ULTRAPLAN line, in which the rapid development of mechanical characteristics and the rapid-drying properties of the binder are exploited, thereby enabling surfaces to be covered by impermeable resilient materials within just a few days, and even within a few hours in the case of ultra-rapid products. Furthermore, the composition of the mix that makes up the binder phase, Portland cement, alumina cement and calcium sulphate, may be controlled to minimise the movements taking place in the product due to hydration reactions. This is very important in the case of self-levellers to prevent detachment and the formation of cracks. These properties are even more evident in the case of ULTRATOP, a self-levelling product with an exposed finish which is formulated depending on its colour with G40 or G70 cement, whose quality aspects are particularly important for aesthetical reasons.

Another fruit of the application of the Górka cement technology is ULTRACOLOR PLUS, a grout used to create coloured joints, with properties that are yet to be matched by any other product available worldwide. Apart from the rapid development of its mechanical properties and shrinkage minimization that allows its application in joints up to 2 cm wide, it contains no Portland cement and, as a result, it does not generate calcium hydroxide crystals during the hydration phase, which would otherwise lead to the formation of efflorescence on the surface of the mortar. In this way ULTRACOLOR PLUS guarantees maximum colour stability.

The chemistry that regulates the mechanisms exploited in the formulation of alumina cement-based products is actually quite complex but the acquisition of Górka by Mapei has generated extraordinary synergic effort between the two companies into research work and production processes, thanks to which, over the years, Mapei products have managed to remain at the absolute technological forefront.