Waterproofing systems for tunnels

Spray-applied polymeric membranes and synthetic membranes for a perfect result in all types of jobsites.

Spray-applied polymeric membranes and synthetic membranes for a perfect result in all types of jobsites.

Maintenance work on existing infrastructures

The construction of infrastructures through the investment of public money is, from a historical perspective, one of the cornerstones of many countries’ economy.

When we talk about sustainability, we immediately think about reducing CO2 emissions, adopting innovative technologies, using more efficient and longer-lasting materials, extending life cycles and then recycling materials.

In the context of underground constructions, maintenance work on existing infrastructures plays a fundamental role, since it is far more cost-effective and sustainable to extend their service life than to construct new ones. Tunnels are obviously no exception.

The environments in which tunnels are constructed are very peculiar and can vary considerably. As a result, projects can be very different: they may be covered with shotcrete or with concrete cast-on-site, or even lined with precast concrete. In all cases, there are certain common fundamental criteria in order to ensure optimal service conditions for tunnels:

- the integrity of the coating or lining which must preserve its structural support capacity;

- the waterproofing of the infrastructure so that any infiltrations of water from the ground do not damage service equipment, resulting in disruptions for users.

Waterproofing tunnels lined with shotcrete

Mapei’s UTT (Underground Technology Team) has an extensive array of technologies, products and systems available to meet all the needs and requirements of designers and construction companies when they face problems encountered on site during underground construction projects.

In this article we will present two waterproofing systems recommended for repairing and strengthening tunnels lined with shotcrete, which are widely used in road and railway tunnels. Shotcrete is a very versatile material and, historically, is used to support and strengthen tunnels bored out using traditional methods because, due to the way it is applied, it enables work to progress quickly without having to use formwork.

Technologies currently available on the market, such as admixtures, superplasticisers and alkali-free setting accelerators, as well as synthetic structural fibres and modern shotcrete spray equipment, enable high quality concrete and more durable structures to be easily obtained.

On the ground side, shotcrete comes into contact with potentially aggressive substances, such as sulphates or aggressive water that could easily penetrate into the matrix of the material, which is more porous and less dense than cast-in-situ concrete. Also, shotcrete is not free from the risk of carbonation, and to this we must also add the effect of other aggressive elements present in exhaust fumes from vehicles (cars and lorries in road tunnels and diesel trains in older rail tunnels). Lastly, shotcrete is often applied in combination with metal strengthening elements such as nets and bolts, metal mesh and “Bernold” sheets: it is, therefore, a type of lining that is highly vulnerable when exposed to various types of aggressive agents: attack from chemical substances (sulphates and acid-basic reactions), infiltrations of water, delamination and cracking provoked by oxidation of metal elements when carbonation penetrates through the lining. These factors all play a part in the deterioration of the lining and, as a result, compromise its structural capacity.

Mapelastic TU System

Any repair and/or strengthening project on an existing tunnel must include a waterproofing system that protects the new lining from aggressive agents and the presence of utility systems.

MAPELASTIC TU SYSTEM is a spray-applied polymeric membrane for waterproofing underground tunnels and structures. It is highly flexible, has high tensile strength and adheres very firmly to cementitious substrates such as, of course, shotcrete.

Once applied to the substrate, MAPELASTIC TU SYSTEM forms a waterproof barrier with excellent adhesion properties, which makes it ideal for creating “sandwich” type waterproofing systems applied between layers of shotcrete or cast-in-situ concrete (with the substrates properly prepared) and shotcrete.

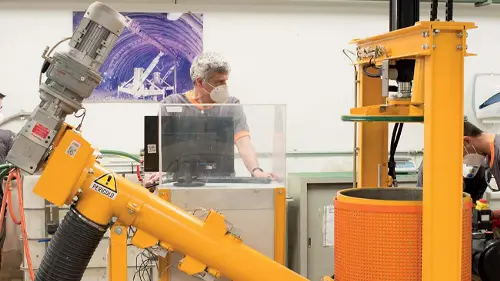

This product is ready to use and needs to be applied with a high-pressure, airless pump, which makes application more practical, faster and cleaner without giving off dust into the environment, and makes it possible to carry out other activities in the tunnel at the same time.

The consumption rate is around 4 kg/m² every 3 mm of thickness, which creates a certified waterproofing capacity of more than 15 bar water column. It may be applied in a single layer or in two steps (two layers at a rate of 2.0 kg/m2), applying a first layer of white MAPELASTIC TU SYSTEM followed by a second layer of green MAPELASTIC TU SYSTEM a few hours later. Applying the product in two layers gives better final results and has several advantages:

- better control of how it covers the substrate thanks to the contrasting colours: a first white layer over grey concrete and a second green layer over the white one;

- consistent final thickness over the entire surface where it is applied;

- better control of consumption.

The excellent adhesion properties of the membrane means that the substrate and the new lining work as one from a structural perspective, while strengthening of the concrete can be achieved by using synthetic fibres or structural metal fibres.

The peculiar characteristics of MAPELASTIC TU SYSTEM also make it ideal for creating a preventive waterproofing system, or for use in areas where the amount of water infiltrations is not particularly high. Existing water infiltrations must be treated beforehand by injecting resin.

MAPELASTIC TU SYSTEM may be combined with other waterproofing systems, such as PVC-P synthetic membranes. In fact, in tunnels where there are a lot of infiltrations, carrying out preliminary work to seal or drain off water can be laborious or too costly. There are other systems – such as PVC-P membranes – which, in such cases, are far more effective.

The Mapeplan TU Line

Synthetic membranes from the MAPEPLAN TU line, with their distinctive orange signal layer, are specifically designed for waterproofing tunnels, usually in which the final lining is created using formwork, although they may also be used in those with a shotcrete lining. In this case, it is fundamental to apply a reinforcement mesh before applying the spray-applied coating because there is practically no adherence between concrete and PVC.

When using this system, it is recommended to install a membrane from the MAPEPLAN PROTECTION line over the MAPEPLAN TU membrane to prevent damaging the waterproofing membrane when installing reinforcement meshes or during application of the shotcrete lining.

Thanks to a watertight anchoring element, MAPEPLAN ANCHORING, it is possible to anchor the reinforced shotcrete to the substrate mechanically, thereby guaranteeing the maximum level of waterproofing for the system. MAPEPLAN ANCHORING is a precast element consisting of a steel bar embedded in a rigid, PVC case, which is installed into the concrete with the use of MAPEFIX VE SF resin, to form an anchor point with a load capacity of more than 120 tonnes. Once installed, the in-built flange is heat-welded to the main membrane to seal the hole.

The two waterproofing systems described in this article may be interconnected, or a transition zone may be created between the two systems by applying MAPEPLAN TAPE PVC, flexible PVC sealing tape to create a continuous waterproofing system, both widthways and lengthways, according to specific project requirements.