Using uncoupling membranes when installing ceramic and stone

An effective solution for renovation work and new builds in the civil and industrial building sectors.

An effective solution for renovation work and new builds in the civil and industrial building sectors.

When installing new ceramic flooring or carrying out renovation work, the design stage is a very important part of the process.

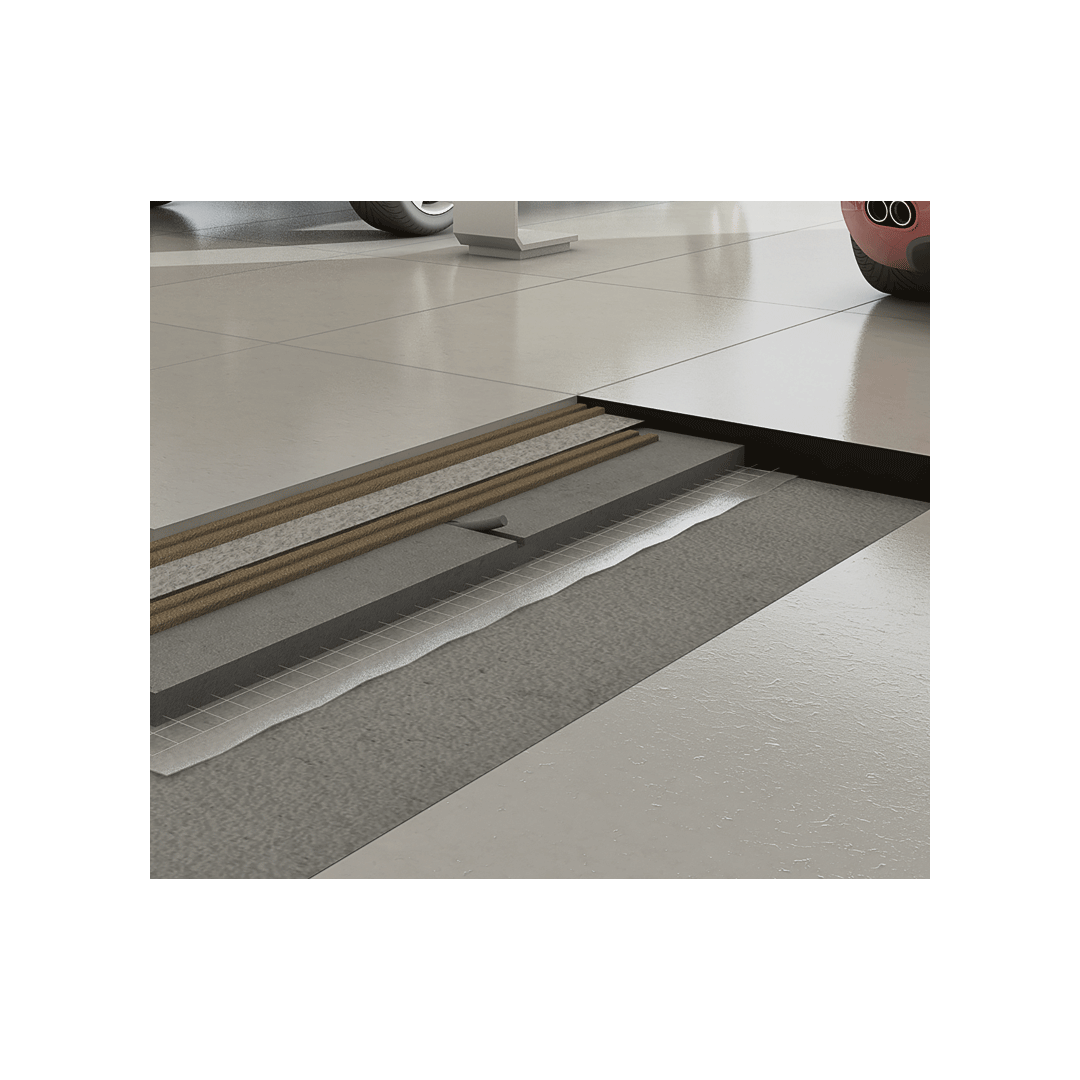

The elements that normally make up the various layers of a floor, from the concrete to the product used to grout joints, are all inter-connected and determine the overall behaviour of the floor covering.

In certain cases, particularly, but not only, with renovation work, the installation layer for the new ceramic or natural stone floor covering no longer complies with the requirements of applicable norms and standards to receive the flooring.

Or, it could be that the more technical conditions of the substrate, such as the joints in the screed, do not coincide with the technical/aesthetic requirements of large size porcelain tiles.

And it is in situations such as these that an uncoupling membrane is used.

Why should we use an uncoupling membrane when installing ceramic flooring?

Particularly when carrying out renovation work, there can be problems with substrates or substrates might no longer meet the specified requirements. If factors such as moisture, continuity (the presence of control or expansion joints), stability or waterproofness are not approached correctly, they could have a negative influence on the correct installation of the flooring.

We should also add that, for a number of years now in various countries, the production of thin, large-size porcelain tiles has become more and more widespread.

These tiles give surfaces a more monolithic aspect and there are far fewer joints in the floor covering.

It often happens that the position and layout of the joints in the screed does not coincide with the format or pattern of the large-size porcelain tiles to be installed.

Or, when installing over existing tiling, the old flooring includes joints which, at least in theory, should be respected because of the movements they are subjected to. Installing a new floor covering would mean cutting the tiles in correspondence with these joints, thereby permanently losing one of the most appreciated aesthetic features of this type of tile.

An excellent solution to this type of problem is an uncoupling membrane. The membrane is positioned between the new flooring and the old substrate, preventing any underlying strains from damaging the new floor covering.

What are uncoupling membranes?

In the absence of a clear, unequivocal international reference standard, it is worth remembering that isolating membranes are defined in the Handbook of the Tile Council of North America (TCNA) as geometrically plastic membranes designed to create an air-gap between ceramic flooring and the substrate.

If we extend our view to include other important functions attributed to membranes, we find soundproofing membranes, anti-fracture membranes, waterproofing membranes and isolating membranes with characteristics that at times overlap, but which can also be different to meet specific design and site needs.

What is the actual purpose of uncoupling membranes?

This type of membrane allows the flooring and substrate to be independent of each other, thereby limiting the transfer of strains into the flooring. It is clear, therefore, that the use of an uncoupling/uncoupling membrane allows ceramic flooring to be installed, including large-size tiles, without being obliged to respect the joints in the substrate.

The membrane may be bonded to the existing substrate using the same adhesive as for the flooring material.

In other cases, the membrane may simply “sit” on the old substrate (such as old flooring or a cementitious substrate) and then receive the new floor covering material.