Underground powerlines in Saint-Denis (France)

The project - the first of its kind in France – involves boring out tunnels in a highly built-up area with road, rail and river infrastructures.

The project - the first of its kind in France – involves boring out tunnels in a highly built-up area with road, rail and river infrastructures.

Powerlines underground

In preparation for the 2024 Paris Olympic Games, and construction of the Olympic and Paralympic Village in particular, work is ongoing in Paris and its outskirts to run powerlines underground and free-up more than 80 hectares of land. In fact, by 2024, the local provider RTE (Réseau Transport Electricité) is planning to run four 225 kilovolt powerlines underground, which are going to substitute 15 km of cables running on 27 pylons and pass through the towns of Saint-Denis, Villeneuve-la-Garenne and l’Île-Saint-Denis, close to the French capital. This intervention is part of the Mesil (Mise en Souterrain d'Initiative Locale) project.

The sheer size of the project is awe-inspiring – and the first of its kind in France – and will involve boring out deep tunnels in a highly built-up area where numerous road, rail and river infrastructures are located. Work is carried out on extremely important powerlines that feed the Gare du Nord railway station, Line 13 of the Paris Metro and the entire area to the north-west of the city (with a population of more than 800,000). There are other sites currently ongoing in the same area which means work needs to be very carefully coordinated, also taking into account the future reorganisation of the urban layout with 2 km of tunnels at a depth of 50 m.

2.5 km long tunnel running at a depth of 50 m

To overcome the challenges of this part of the project, RTE opted for the construction of an underground tunnel through which the new powerlines will pass: an appropriate solution for a particularly congested and densely populated area. The tunnel, around 2.5 km long, is 3 m in diameter and runs at a depth of 50 m. For the tunnelling work, carried out by a 120 m long TBM with a diameter of 3.9 m called Ambra, 120.000 liner segments had to be installed.

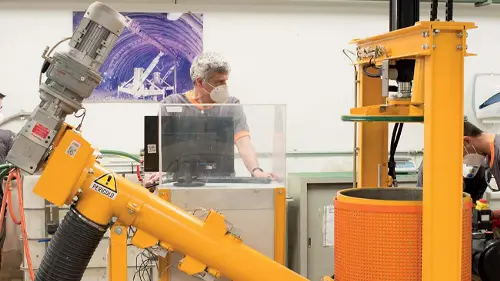

Backfill grouts with mapei two-component systems

While tunnelling, a TBM leaves an annular void between the ground and the extrados of the segments when they are placed in position and this void has to be filled as the TBM advances. Depending on particular site constraints and decisions taken by the main contractor, the voids may be filled with grouts or two-component grout, in which component A is made from water, bentonite, cement and a set retardant and component B is a set accelerator .

The two-component system proposed by Mapei, thought to be the most suitable for this site by the main contractor Spie batignolles, had already been used on other sites such as Lots T2A and T2B of the 15 Line South of the Gran Paris Express project (see Realtà Mapei International no. 92), the extension of the safety tunnel for the RER C in Meudon and site SMP4 for the Tunnel Euroalpin Lyon Turin (TELT). Because of the constraints imposed by the mechanical properties required, along with the high pressures due to the sheer depth of the tunnel, a preliminary study had to be carried out in the Mapei laboratories. The products proposed are the following:

- MAPEQUICK CBS SYSTEM 3: a liquid product used as accelerator of cement-based mixes for injection, particularly suitable for extremely fluid mixes with a very high content of water.

- MAPEQUICK CBS SYSTEM 1: a liquid retarding agent with plasticizing effect which inhibits the setting times of cementitious mixes for long periods. It is specifically designed for cementitious mixes that need long workability times, for example, because of long transportation times or long pumping distance.

- MAPEBENT API 2: a natural sodium bentonite suitable for every type of civil engineering application fields. It conforms the international API specifications about materials to be used for drilling fluids and bentonite based slurries and can be used in every civil engineering application fields, especially where a quick activation of bentonite in water is required and where the mix should have an easy pumpability and high volumetric stability.

This article was taken from issue N° 52 of Mapei et Vous, the magazine published by Mapei Group’s subsidiary Mapei France, whom we kindly thank.

Because of the constraints imposed by the mechanical properties required, along with the high pressures due to the sheer depth of the tunnel, a preliminary study had to be carried out in the Mapei laboratories.