Interviewee

Takafumi Noguchi

Professor at the Department of Architecture, University of Tokyo

Professor Takafumi Noguchi shares his views concerning current pratices to treat and recycle concrete waste in Japan and Europe

How high is the awareness in Japan concerning the environmental impact of returned concrete and washing water slurry?

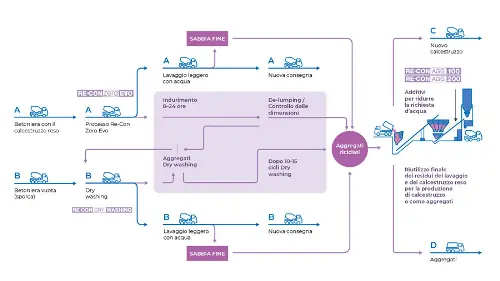

I am aware that in Europe it is common to discharge returned concrete on the ground, let it harden, crush it and use the hardened recycled aggregates to manufacture new concrete. This also happens in Japan, but most Japanese concrete manufacturers are not willing to use such aggregates for new concrete. Even if there is a national standard allowing their use, only a small amount of recycled aggregates (probably less than 1%) is used in the manufacture of new concrete. They can be used but their use is discouraged. So environmental awareness in Japan is not yet enough high for allowing a wide use of these materials.

"Even if there is a national standard allowing their use, only a small amount of recycled aggregates (1%) is used in the manufacture of new concrete in Japan"

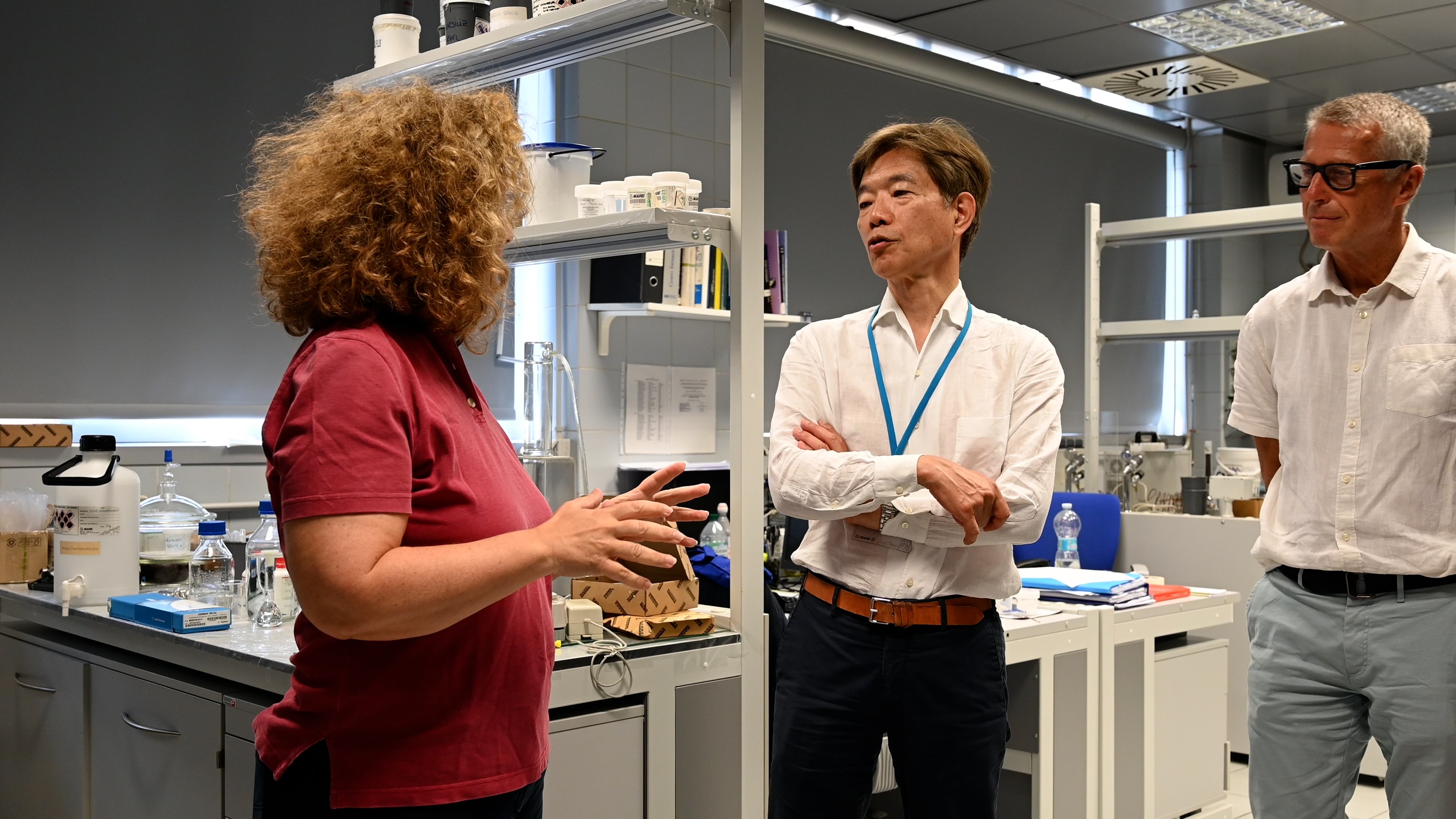

Professor Noguchi visited Mapei Research & Development Laboratories in Milan in July 2023

In your opinion, what is the most important factor to be able to increase the usage of recycled aggregates in new concrete in Japan?

Standards and governmental incentives are very important to achieve this goal even if they are not the only key factors. I am aware that, as current European standards, such as EN 206, allow to use a maximum of 5% of reclaimed aggregate in new concrete; so, European concrete manufacturers can use up to 5% of reclaimed aggregate for new concrete without any restriction. In Japan we have a similar standard that allow us to use recreated aggregates, but we need to wash them: no dry system is permitted. Currently we are working on a new standard which will allow us to use the dry system to make granulated aggregates by using such additives. Nevertheless, the use of reclaimed aggregate in Japan is limited.

Even if the Japanese government incentives the use of the recycled materials rather than natural crushed aggregates for the concrete used for public works, many concrete manufacturers and construction companies do not like to use these materials. This is also due to the fact that demolition of structures mainly takes place in the cities, while the construction of new roads takes place in rural areas, so there is some distance between the places of production of returned concrete and the places where new concrete is manufactured which creates the need for transportation which, in turn, generates new environmental disadvantages.

“Sustainability is a decisive issue: to achieve this objective collaboration with other sectors of industry is vital”

Professor Noguchi visited Mapei Research & Development Laboratories in Milan in July 2023

Quality is also crucial: we need to be sure that the recycled aggregates are able to make concrete keep its properties constant both in the fresh and hardened state. This is why we look at the new developments by Mapei with high expectations and are willing to work together with Mapei in this field.

Besides, it is important to cooperate with other industries so that we can work together on the reduction of carbon dioxide on the road to carbon neutrality.

Takafumi Noguchi is currently Professor at the University of Tokyo, Department of Architecture. He holds many prestigious positions in the field (Vice-president of Architectural Institute of Japan, President of Japan Society for Finishings Technology, Chief Director of Ready-mixed & Returned Concrete Solution Association, Chair of ISO/TC71/SC8) and was awarded several prestigious prizes (Excellence Award in Concrete Construction of ACI in 2017, Awards for Outstanding Concrete Structures in Building Category of fib in 2018, Technology Award of Japan Concrete Institute in 2021). His main fields of research include carbon-neutral concrete, sustainable recycling and optimum resource circulation of concrete, performance assessment and conservation of historical concrete structures, durability design and optimum rehabilitation of concrete structures.

Find out more about Mapei solutions for the concrete industry at: https://www.mapei.com/cis/en/home-page