The new tall building houses Unipol's new headquarters and is intended to accommodate more than 600 people

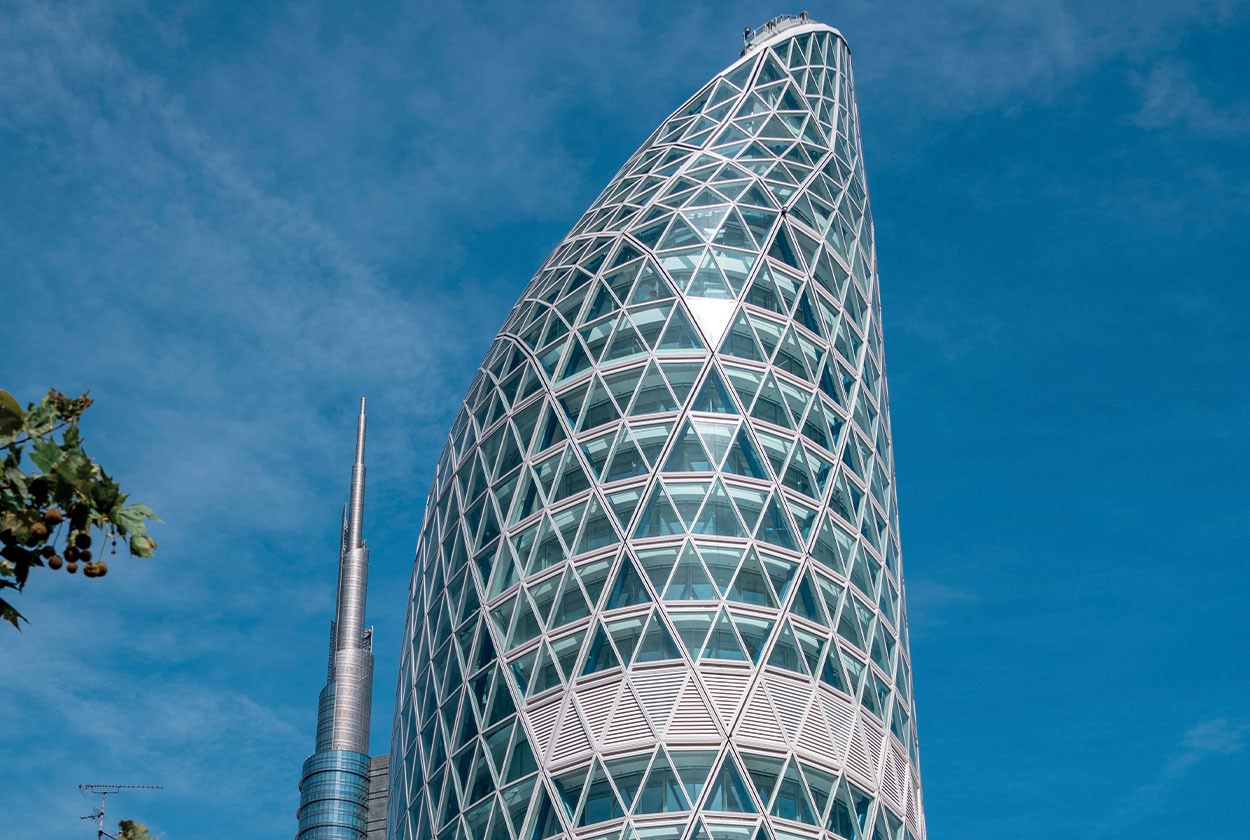

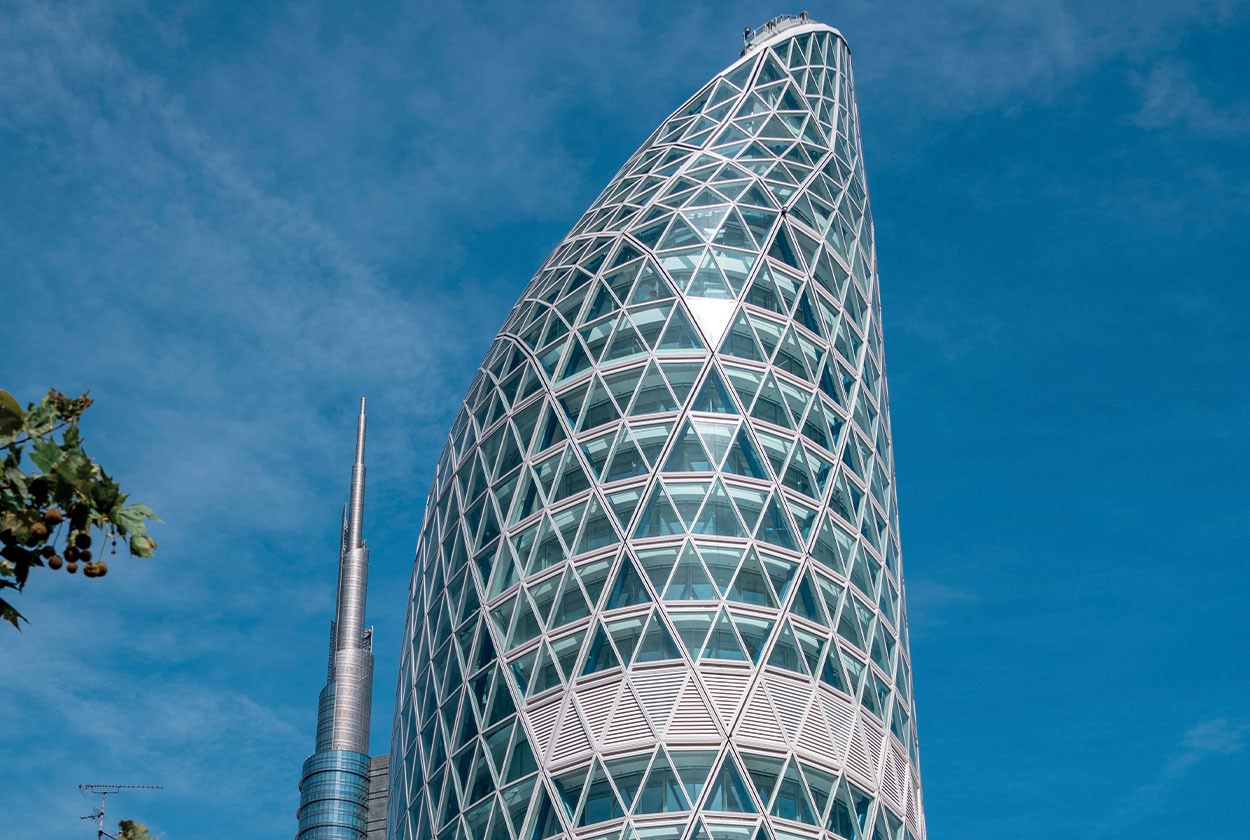

Completion of Torre Unipol, designed by Mario Cucinella Architects (MCA), concludes one of the most important and imposing urban redevelopment projects undertaken this century in Milan and focusing on the Porta Nuova district. Construction of the new skyscraper started in 2018 and required meticulous preparation from a design and technical perspective. In fact, a cutting-edge site was created characterised by a vertical structure which occupied only a minimum amount of space at its base. The structure rises up on a small plot of land at the corner of Via Melchiorre Gioia and Via Fratelli Castiglioni. In 2014 Unipol chose this plot for its new group headquarters and, once fully operational, it will accommodate more than 600 people. After invitations were sent out to compete in the international competition for its design, the project was awarded to the MCA architectural and design firm.

A cutting-edge skyscraper

Construction of the tower started in 2018 with the insertion of the foundation piles, while the first stone was laid in the spring of 2019. The most interesting feature of the tower is its sensorial double shellt. The façade, in fact, was created out of curvilinear steel pillars intersecting with each other. The materials used for its construction are mainly glass, steel and concrete.

Right from the very start the building was designed to maximise energy efficiency, thanks to a double shell along the external wall with the function of mitigating heat in summer and insulating against cold weather in winter. The geometry of the external structural shell, consisting of triangular glass modules set in a blue and white metal framework, also contributes to guaranteeing the tower’s energy efficiency. To increase energy efficiency of the building even further and reduce consumption of resources to a minimum a geothermal heat pump was installed, as well as photovoltaic panels, a mechanical ventilation system to recycle hot air and a rainwater recovery system. These characteristics will enable a request to be submitted for LEED Platinum certification.

Design, height and so much sustainability

The building, which will be inaugurated by the end of the year, is 23 storeys high and has 3 floors below ground level, with an overall height of 125 m and a total surface area of 33,000 m2. Once the best position on the plot of land had been identified, MCA architectural studio defined the form of the tower: a cylindrical, elliptical shaped form was chosen, a solution which enables the dispersive surface to be reduced if compared with a building of similar volume but with a rectangular form.

The enormous, 75 m high atrium is accessible on two levels, one from Via Melchiorre Gioia and the other via a platform in Piazza Gae Aulenti. This space has been defined by the designer as a “climate moderation space”, that is, it is able to use the way it is exposed as an energy opportunity: the atrium, in fact, faces south and acts as a climatic buffer, minimising heat dispersion from the shell and storing heat energy from the sun.

On the upper floors there are the management offices, meeting spaces and a restaurant which will be connected to the bar area via a panoramic stairway. The offices will benefit from passive cooling from the double shell, but not from ventilation coming from the large atrium as they are closed off from the atrium as a fire prevention measure. On the top floor there will be a large greenhouse with an area designed to host public meetings and cultural events: another space without forced conditioning which will benefit from passive cooling, especially in average months, thanks to efficient control of the ventilation outlets in the lower part facing south and in the upper part facing north.

Mapei also played its part

Mapei took part in the construction of the new buildings that have transformed the face of the Porta Nuova district (see Realtà Mapei International no. 49) and contributed to the construction of Torre Unipol by proposing the most suitable systems for various types of work. Here is a summary of the works carried out.

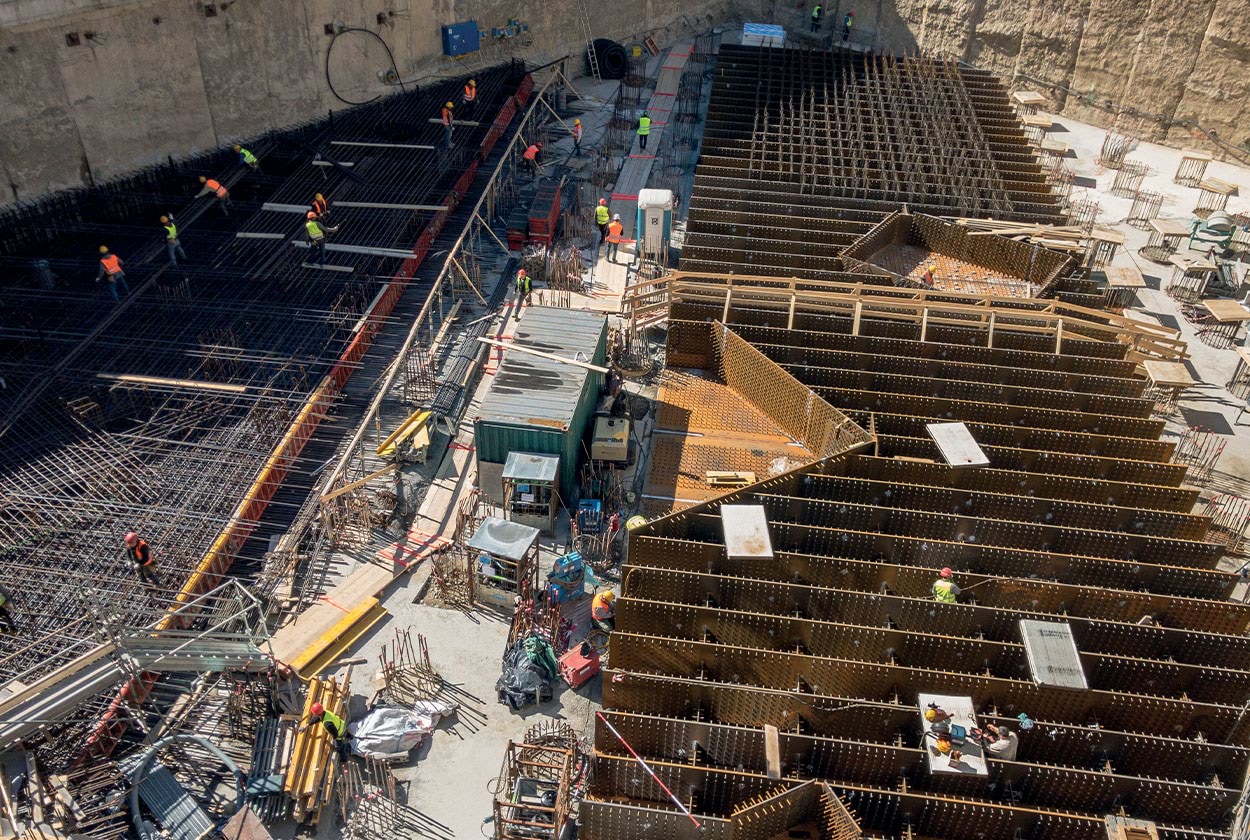

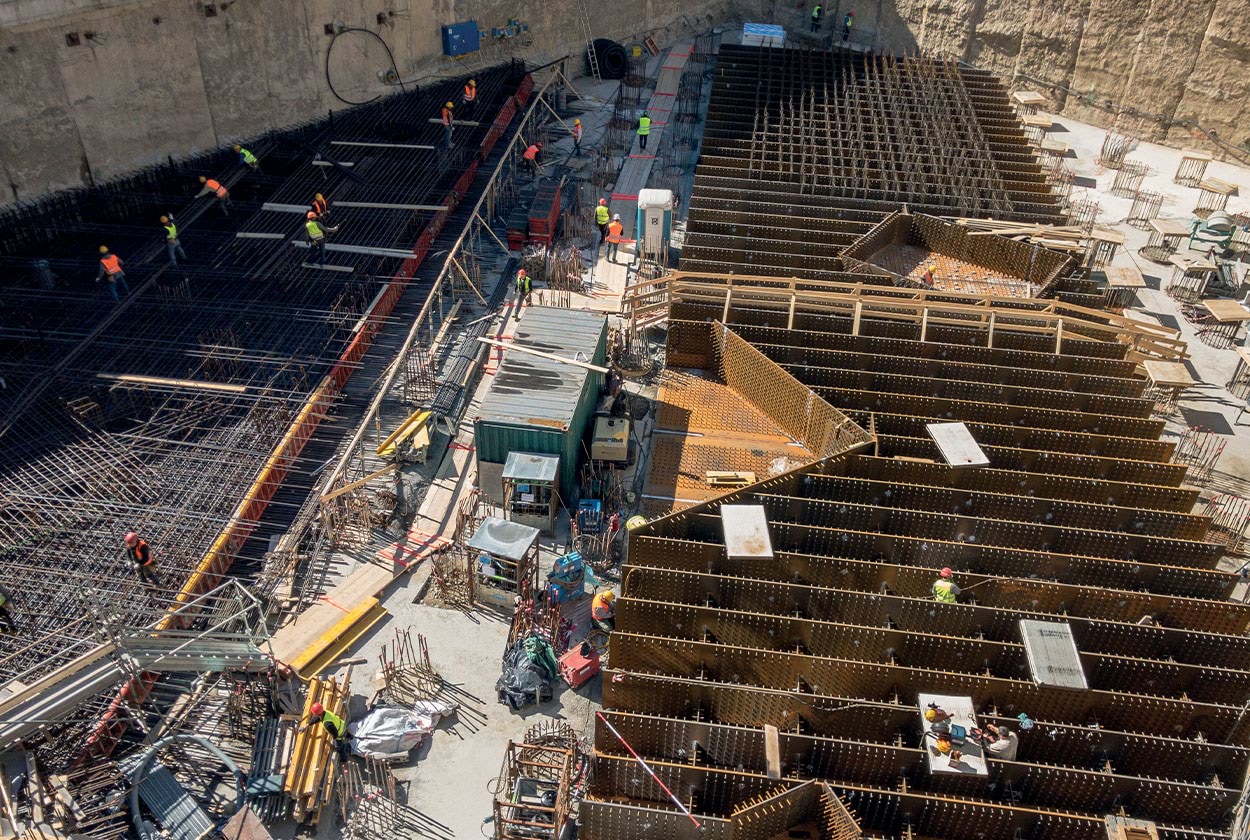

Supply of admixtures for concrete. Mapei supplied the concrete admixtures DYNAMON XTEND W300 N and DYNAMON XTEND W300 R to the cement and concrete producer Holcim for the construction of the foundation slab and vertical structures. Upon request of the construction site supervisor, Mapei also contributed to control the heat development of the concrete used for the foundation slab, which has not to exceed a certain temperature according to current regulations.

Concrete repair. Various portions of concrete needed to be repaired. The first stage of the work was to protect the steel reinforcement rods with MAPEFER 1K, followed by reintegrating the sections from where damaged concrete had been removed with PLANITOP SMOOTH & REPAIR R4 and MAPEGROUT THIXOTROPIC mortars.

Structural strengthening. Work was carried out to improve static and seismic capacity by applying C-FRP composite systems. MAPEWRAP SYSTEM, consisting of MAPEWRAP PRIMER 1, MAPEWRAP 12 epoxy grout, MAPEWRAP 31 epoxy adhesive and MAPEWRAP C UNI-AX HM 300 carbon fibre fabrics , was applied to confine some of the concrete pillars and to improve the shear and flexural resistance of some of the beams.

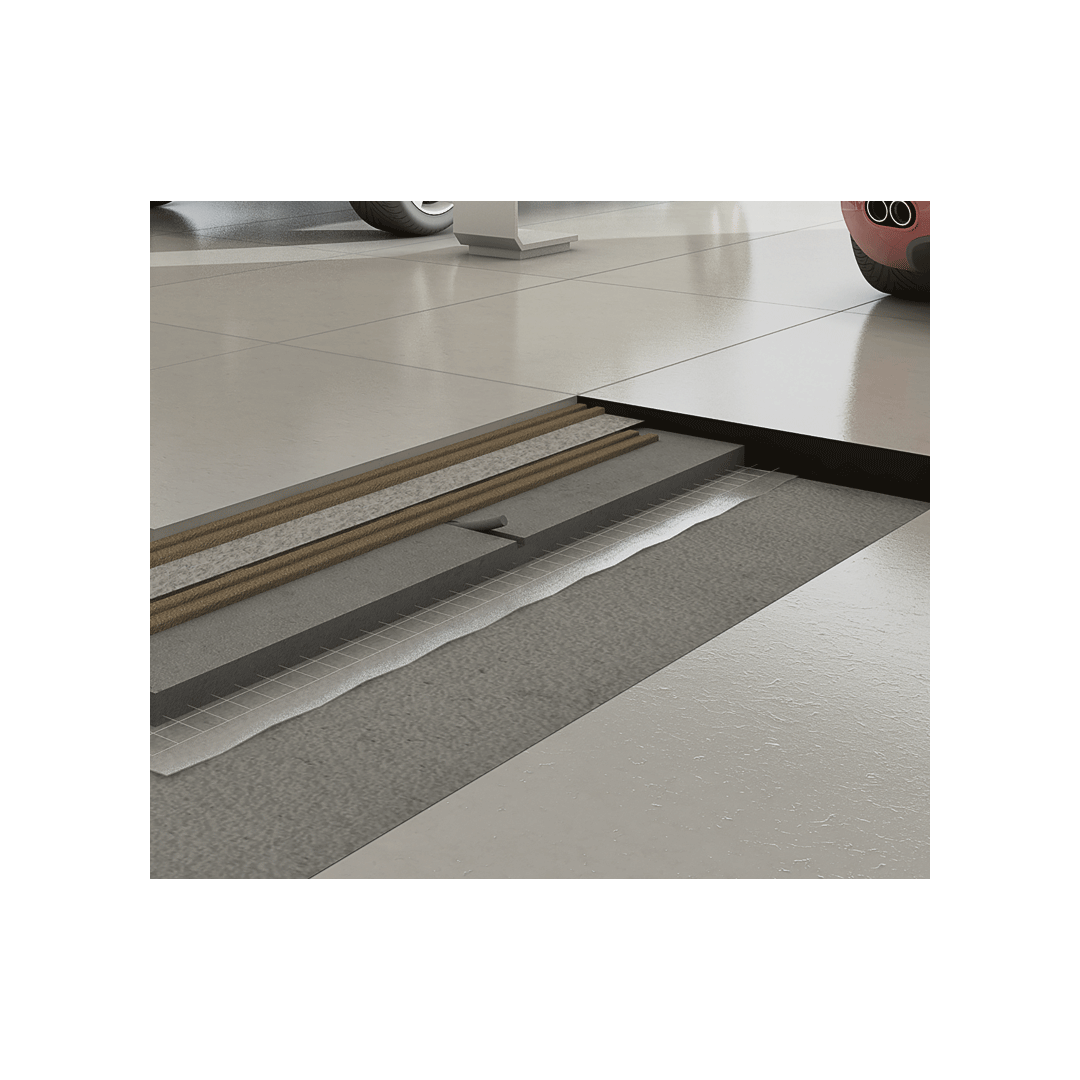

Underground carpark. MAPEFLOOR PARKING SYSTEM RLT was chosen for the floors in the underground carpark, a seamless, multi-layered system used for coating surfaces in areas used by pedestrians and light vehicle traffic.

Resin floorings. MAPEFLOOR SYSTEM 31 was chosen to coat the floors of the stairs and bathrooms, a multi-layered epoxy system applied in layers from 0.8 to 1.2 mm thick, followed by a coat of MAPEFLOOR FINISH 58W that improves the mechanical properties of the surfaces, especially as for their abrasion resistance.

Waterproofing substrates. The substrates in the bathrooms were waterproofed with two layers of MAPELASTIC two-component cementitious mortar, with MAPENET 150 alkali-resistant fibre glass mesh embedded between them and MAPEBAND EASY alkali-resistant tape used for waterproofing the corners between adjacent walls and between walls and floors.

Installation of stone and marble. After installing MAPETEX SYSTEM anti-fracture system on the substrates, the adhesive KERAFLEX MAXI S1 ZERO was used to install 2 cm thick Serena stone slabs, while the joints were grouted with KERACOLOR FF. Marble slabs were installed using ULTRABOND ECO PU 2K adhesive which was chosen due to its capacity to ensure excellent durability and resistance to ageing and perfect adhesion to all types of substrates.

Sealing. MAPEFLEX MS 45 and MAPEFLEX PU 45 FT sealants were chosen for sealing operations in different areas.

Mapei was involved from the earliest stages of the construction of the skyscraper supplying concrete admixtures of the DYNAMON LINE