This is how the external thermal insulation system withstands an earthquake

The test campaign, carried out by the Federico II University of Napes, analysed the behaviour of the multi-floor frames in reinforced concrete

An experimental campaign by the Faculty of Structural Engineering and Architecture of Federico II University of Naples has shown that the use of the external thermal insulation system can help buildings withstanding an earthquake

The building sector is responsible for 40% of energy demand in the European Union and for 32% of global demand, contributing significantly to the emission of pollutants. This is why the European community in primis, and the Italian government, are promoting policies to redevelop and upgrade existing building stock with the aim of reducing energy consumption and, more generally, improving the energy and seismic performance of structures. Even though radical demolition and reconstruction work can appear to be feasible and could receive the financial backing required, it is not practical on a large scale because of the high direct costs, the amount of disruption this would cause for occupiers of the buildings (which would remain inaccessible for several months) and the impact the work would have on the environment. Upgrading/renovating existing buildings from an energy perspective is clearly a key strategy on the road to sustainable development. However, designing and carrying out interventions to improve energy efficiency in territories at high risk of seismic activity must always take into consideration an evaluation of the seismic performance of structural and non-structural components, and coherent actions must be taken to improve their performance whenever, as generally happens, they are required.

A test campaign lately carried out by the Faculty of Structural Engineering and Architecture of Federico II University of Naples analysed the behaviour of a multi-floor frame in reinforced concrete with non-structural infill brick wall to represent an existing building typical of Southern European building stock A thermal insulation system produced and distributed by Mapei was applied on the structure. The system was applied on the external side only to simulate the most common and least invasive type of application. The primary objective was to quantify how well the external thermal insulation system holds as the intensity of an earthquake increases, and also to assess the amount of damage to the insulation system, the infill wall and the structural system in general.

These activities were carried out as part of the consolidated working relationship established between Mapei S.p.A. and DiSt - Dipartimento di Strutture per l’Ingegneria e l’Architettura dell’Università degli Studi di Napoli-Federico II (Department of Structures for Engineering and Architecture of the Federico II University of Naples) into the research, development and validation of sustainable solutions for the building sector using innovative materials.

Test campaign: programme and method

Testing was carried out on two multi-floor, reinforced concrete with infill walls. The structural system was characterised by concrete with limited mechanical properties (fcm = 19-24 MPa) and steel reinforcement typically found in existing buildings designed at the end of the 1970’s. The full-scale frame was a reproduction of a real building damaged during the earthquake that struck the city of L’Aquila (Central Italy) in 2009, with a 20 cm thick double-infill wall and a frame 6.3 m high by 4.1 m wide; the mechanical properties of the materials and construction details also reproduce those of the original building.

The experimental test campaign was carried out on two frames; one to reproduce the original as-built condition, and a second frame with a thermal insulation system applied on the external side only. The tests were carried out using two actuators with a capacity of 1200 kN connected to an opposing wall. The frame was connected to a horizontal contrast plate with a system of shear connectors embedded in the concrete and 16 prestressing bars. The normal load at the top of the pillars (N= 300 kN) was applied by jacks acting against a rigid steel girder anchored into the foundations with steel rods to allow for rotation along the plane of the frame. The loading protocol in terms of the amount of displacement imposed by the actuators on the two floors was defined and updated in real-time according to the stiffness of the frame by means of a pseudo-dynamic test framework. The assigned accelerometric input in this particular case (to simulate the L’Aquila earthquake in 2009, acceleration station AQG, PGA = 0.45g) was scaled for variable and increasing intensity, from a peak value of 10% PGA up to 150% PGA.

External thermal insulation system

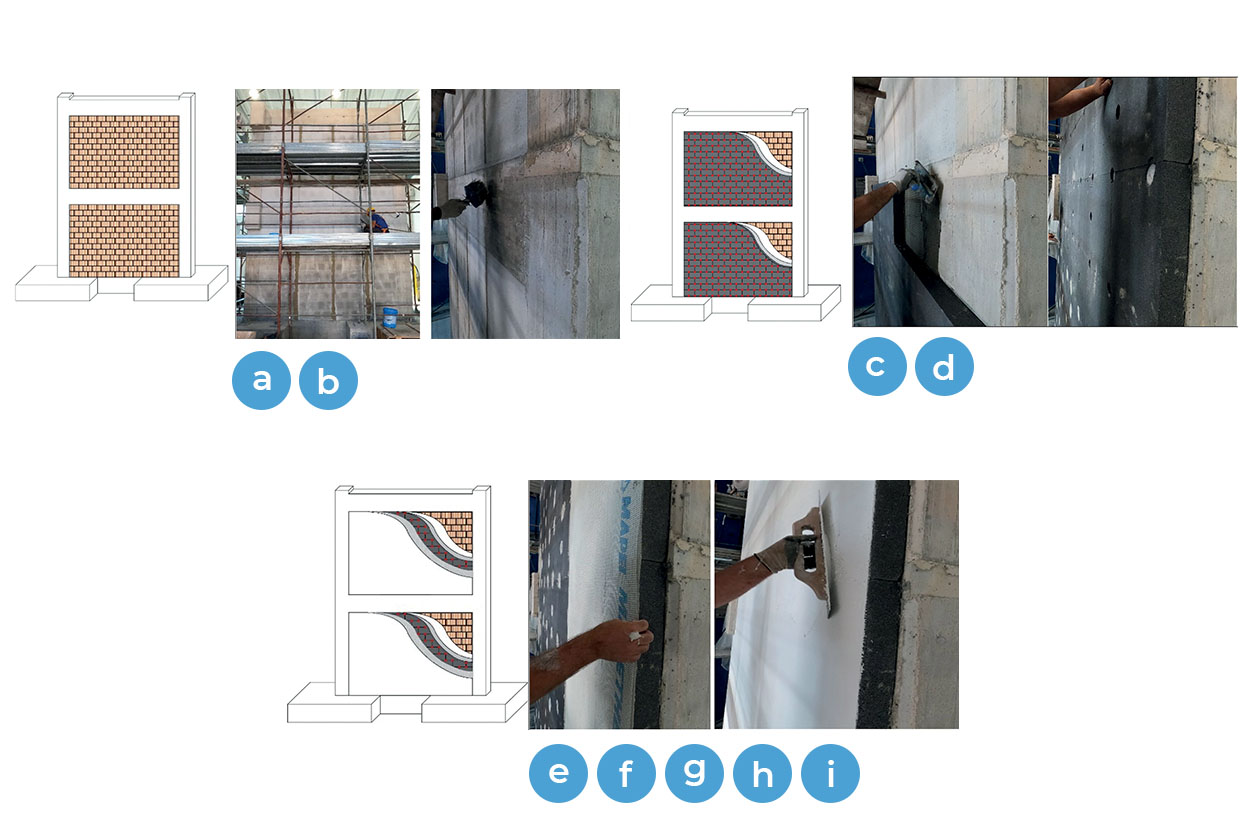

The external thermal insulation system was applied on the whole of the external surface of the frame, forming a continuous cover over the infill-wall and reinforced concrete frame to eliminate any thermal bridges. The installation phases of the system (shown in Fig 1) are summarised below.

(a) Application of INTOMAP FIBRO R2 cementitious base render on the wall;

(b) Application of MALECH primer;

(c) Application of MAPETHERM AR1 cementitious adhesive and installation of MAPETHERM EPS expanded polystyrene insulating panels;

(d) Installation of MAPETHERM SYSTEM STR U 2G 155 mm fasteners;

(e) Skim coat of MAPETHERM AR1 GG cementitious mortar;

(f) Application of MAPETHERM NET glass fibre mesh;

(g) Skim coat of MAPETHERM AR1 GG cementitious mortar;

(h) Application of MALECH primer;

(i) External finish of QUARZOLITE BASE COAT.

Seismic performance analysis

The pseudo-dynamic tests with increasing intensity on the frame with external thermal insulation showed that the insulation system had the capacity to withstand medium/high intensity earthquakes without sustaining significant damage. The tests showed that the first cracks in the wall (with detachment of the infill-wall at the beam connection point) occurred at 50% of the reference seismic intensity (L’Aquila earthquake in 2009, PGA = 0.45g), similarly to what occurred in the as-built case.

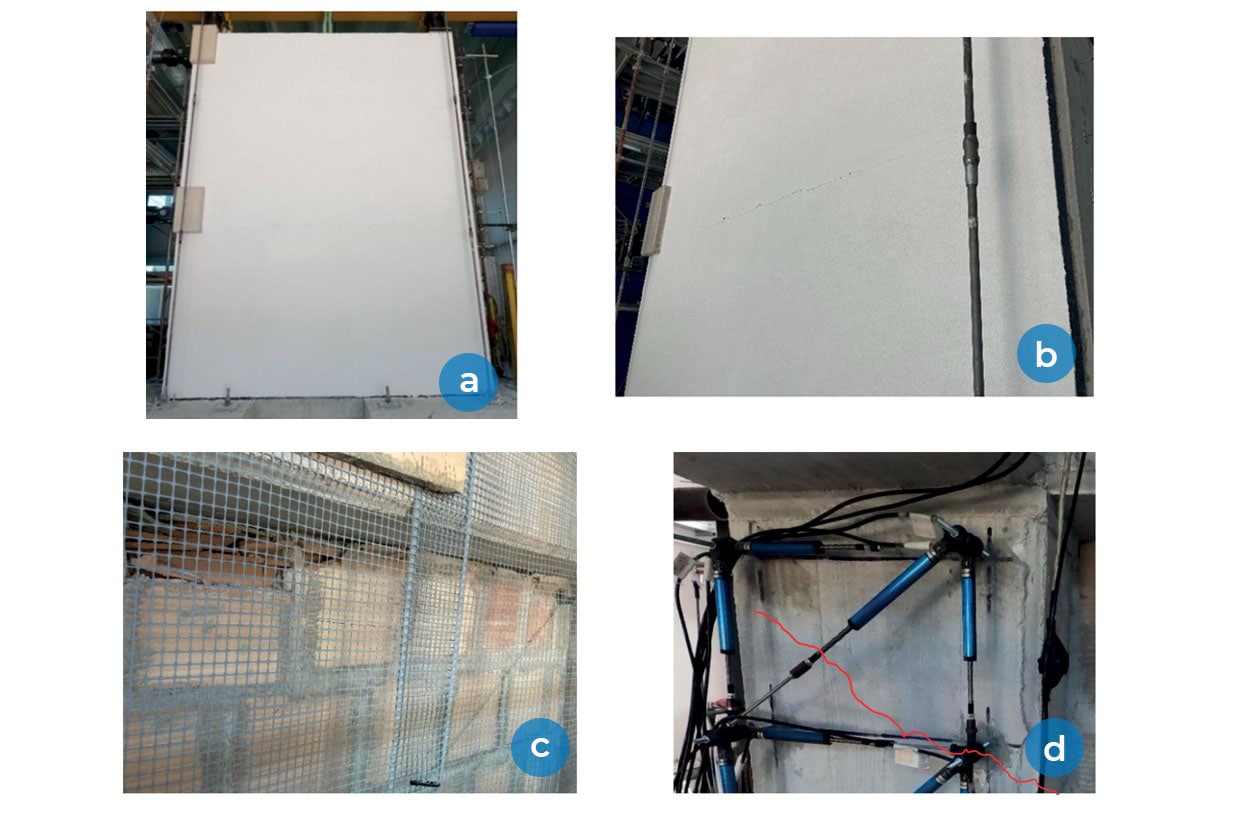

In the successive test phases, as seismic intensity increased, the test piece with the external thermal insulation sustained less evident damage compared with the as-built version; this was due to the effect of the glass fibre mesh used for bonding and the skim coat on the insulation system. At a high rate of seismic intensity, from 125% of that of the earthquake in L’Aquila, a loss of adherence was observed between the insulation system and the wall. During the successive test phases, at 150% and 175% of the seismic intensity of the L’Aquila earthquake, the first sign of damage was observed to the insulation system at the beam-wall attachment point at first-floor level (Fig 2. a, b) and significant damage to the wall (Fig. 2c), with evident diagonal cracks and crushing of the courses of bricks in contact with the beam at both levels. Shear cracking was also observed in the pillar at ground-floor level due to interaction with the wall (Fig. 2d). The presence of shear cracking in the pillar underlines the benefits of an integrated approach when upgrading structures by combining an external thermal insulation system with a composite strengthening system at the end of pillars and at beam-pillar joints to guarantee good seismic performance.

A comparison of the cyclic hysteresis envelopes (Fig. 3.) illustrates how the thermal insulation system, even though it has little incidence on initial stiffness (detachment of the wall from the frame at the same intensity as the as-built version), thanks to the effect of the high performance mortar used to bond the insulation, contributed in increasing the post-cracking resistance and stiffness of the infill-wall and, as a result, the seismic capacity of the frame. Only following the test performed to simulate an earthquake 175% of the seismic intensity of L’Aquila in 2009 was significant reduction in strength observed, in a negative load direction. In fact, the marked cracking in the wall in this phase led to losing the contribution of the insulation system and, therefore, resistance tends to be more similar to the as-built system.