Paolo Fornoni

Research & Development Coordinator - Admixtures for Concrete, Mapei SpA

Paolo Fornoni, Mapei R&D Laboratories: we tried to identify polymers immune to the inter-layer absorption action exerted by the clay and with the capacity to guarantee their dispersive action in the concrete mix

The first studies carried out in the Mapei Research & Development Laboratories into the compatibility of super-plasticising admixtures with aggregates containing clay date back to around ten years ago. Clay is a phyllosilicate mineral made up of hydrated layers of aluminosilicates. Depending on the configuration these layers mutually assume, clay can have from a low to highly “harmful” effect during the concrete mixing phase. In fact, some types of clay have the capacity to trap large quantities of water between one layer and another and, what is even more serious, they are able to capture the polymers that form the basis of super-plasticising admixtures. It only requires a very small amount of clay in the aggregate to drastically reduce the effectiveness of an admixture. There are basically two ways of counteracting this phenomenon when formulating admixtures: to find “sacrificial” substances in order to deactivate the clay or to identify polymers immune to the inter-layer absorption action exerted by the clay and with the capacity to guarantee their dispersive action. Research carried out by the Mapei Laboratories analysed both methods, but the solution was found with the second.

"Clay can have from a harmful effect during the concrete mixing phase. We tried to identify polymers immune to the inter-layer absorption action exerted by the clay"

Study of sand and the search for the right polymer

Behind the success of this project there was an important study of the types of sand used by the leading concrete manufacturers in Italy and abroad. The composition of the various types of sand was analysed thanks to special XRD and TGA techniques to qualify and quantify the amount of clay contained in them. Apart from analysing their composition, standardised techniques were applied to quantify the content of harmful clay using the methylene blue method. It was important to be able to construct a laboratory test sample in mortar, adding a certain type of clay to the normalised sand to represent what would be the large-scale effect in concrete mixing plants. Thanks to the collaboration with the Polymers Department of our R&D Lab, it was possible to evaluate numerous synthesised polymers for this scope. After numerous experiments a polymer was identified with a structure that was only minimally affected by the absorption of the clay or, as would seem to have been demonstrated in more recent studies, with the capacity to shield the clay particle, inhibiting access to the rest of the polymers inside the layers.

"After numerous experiments a polymer was identified with a structure that was only minimally affected by the absorption of the clay or with the capacity to shield the clay particle"

During the research work at R&D laboratories, a flow table was also used to assess the mix flow rate.

Arrival of the RE-CON AGG admixtures

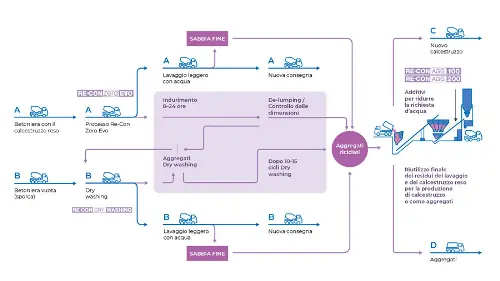

The first product of this type launched on the market, RE-CON AGG 100, was proposed as an admixture to be used in combination with other super-plasticising admixtures from the DYNAMON range. Its action, especially when added in the first phase of the mix, shields the clay and promotes the action of the super-plasticising admixture added afterwards. The combined action of the two admixtures creates concrete with the same characteristics as a formulate without clay, but with excellent workability of the fresh mix. Because the market also required an “all-in-one” product, two more products were developed: RE-CON AGG 200 (for summer use) and RE-CON AGG 400 (for winter use). These products perform both a mitigating action on the clay and a super-plasticising action. Apart from being highly effective in concrete containing clay, products from the RE-CON AGG range mitigate the effect of recycled aggregates, which are becoming more and more widely used in the concrete industry to partially replace virgin aggregates.

Find out more about Mapei solutions for the concrete industry at: https://www.mapei.com/cis/en/home-page

"The first product of this type launched on the market is RE-CON AGG 100 admixtures, followed by RE-CON AGG 200 (for summer use) and RE-CON AGG 400 (for winter use)"

The Re-con AGG admixtures range was developed thanks to a complex Research & Development project at Mapei R&D Laboratories in Milan.