The Church of Santa Maria Annunciata

Façade restoration and safety measures implemented on the upper part of a place of worship designed by Gio Ponti

Façade restoration and safety measures implemented on the upper part of a place of worship designed by Gio Ponti

The Church of Santa Maria Annunciata, designed by Gio Ponti and built between 1964 and 1966, is located in San Carlo Hospital in Milan.

The renowned architect’s idea was for it to become a place of worship and, above all, in the words of Gio Ponti himself: “An ark where man and God can come together”.

The church is joined to the hospital by a kind of “gangplank”, similar to that of a ship in dock, and can hold up to 600 people. The North façade and its symmetrical counterpart on the South side are joined by two lateral pinnacles that give the church its characteristic form of a ship. Preceded by a trapezoidal staircase, the North façade is punctuated by three rows of hexagonal windows and is covered externally with ceramic in an alternating pattern of diamond-shaped tiles – that reflect and refract the light – and flat tiles framing the openings in the façade.

This church by Gio Ponti differs from traditional churches in its use of materials and the structure itself and is coherent with one of his precise concepts: “Don’t conserve ideas of ancient styles; rather, conserve the ancient Italian energy of constant transformation. Let’s conserve the manner of the ancients, and by that, I mean the virtues: but not the styles”.

Effective restoration solutions and safety measures

After almost sixty years following its construction the Church of Santa Maria Annunciata underwent important conservative refurbishment work on the façade, which included the use of numerous Mapei products. Apart from refurbishing the clinker covering, maintenance work was also carried out on the upper cornice and its protective metal flashing, which had become badly deteriorated due to carbonation of the rebar, resulting in the displacement of the concrete around the rebar.

The first step was to remove the deteriorated concrete and mortar used to bond the point-shaped tiles. The rebar was then treated with MAPEFER 1K one-component, corrosion-inhibiting cementitious mortar.

The surfaces from where concrete had been removed were then reintegrated with MAPEGROUT 430 fine-textured, fibre-reinforced thixotropic mortar, the ideal product for repairing concrete structures.

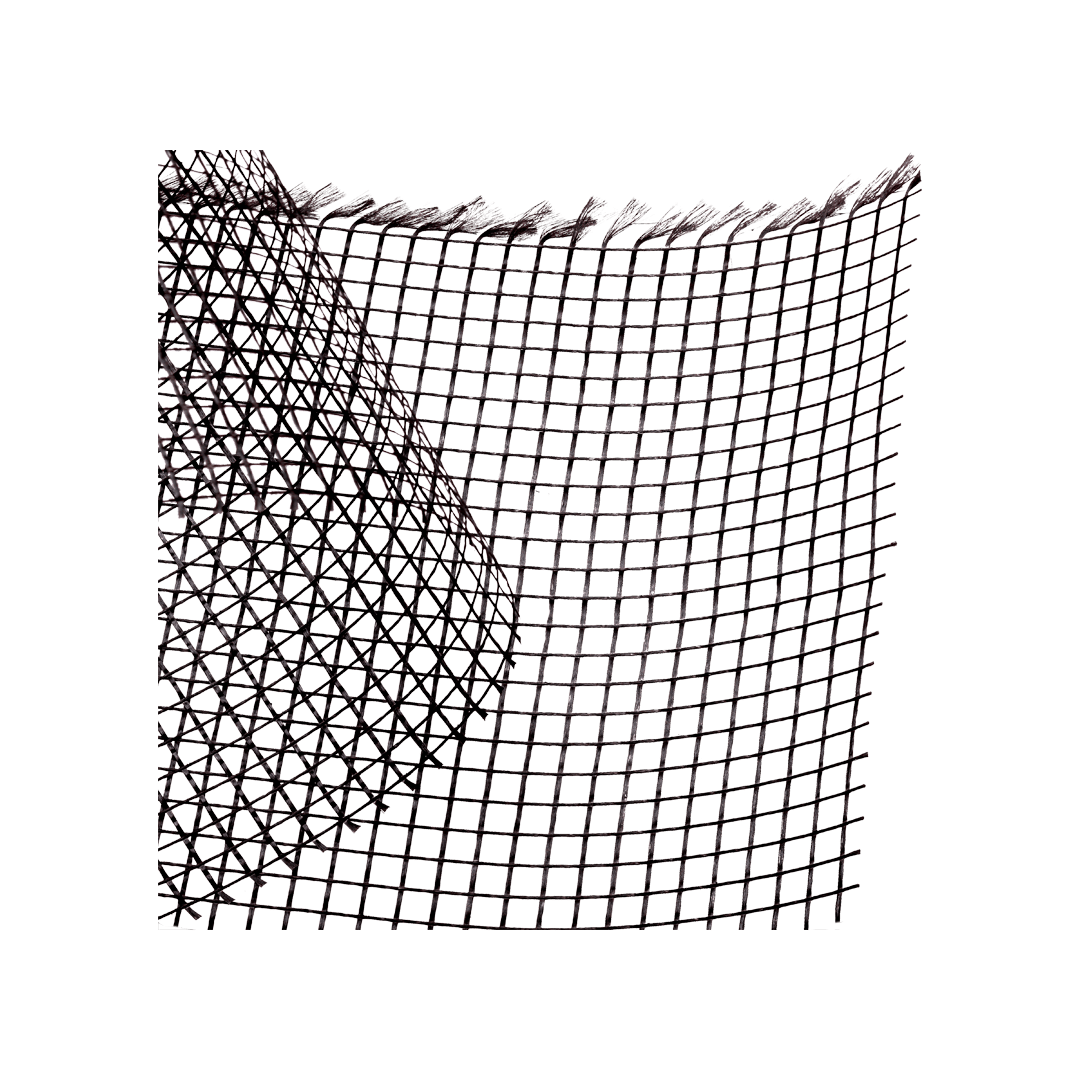

Because of the amount of concrete that had been removed, Mapei Technical Services recommended creating new additional reinforcement by fixing steel elements on the healthy layer of the concrete Once the areas of missing concrete had been reintegrated, structural render was created by applying PLANITOP HDM MAXI – two-component, ready-mixed cementitious mortar for “reinforced” structural strengthening applications – in two layers, with MAPEGRID G 120 alkali-resistant, glass fibre mesh embedded between the two layers.

After waiting 10-15 days for the structural render to cure, the ceramic covering was bonded back in place with KERAFLEX MAXI S1 deformable, cementitious white adhesive and grouted with KERACOLOR FF high performance, polymer-modified, water-repellent cementitious mortar which is used for joints up to 6 mm wide. To improve performances, KERACOLOR FF was admixed with around 20% of FUGOLASTIC liquid polymer admixture.