Russia 2018: innovation takes the field

Mapei technology for 8 of the 12 stadiums hosting the matches of the 2018 Fifa World Cup.

Wherever a sporting event offers so much excitement that it breaks down national borders and is shared on a global level, Mapei is there. And the Group is also there alongside the players, with research scientists from the Mapei Sport Centre, or as one of the main sponsors of the competition or as a supplier of products of excellence used to build the stadiums and arenas.

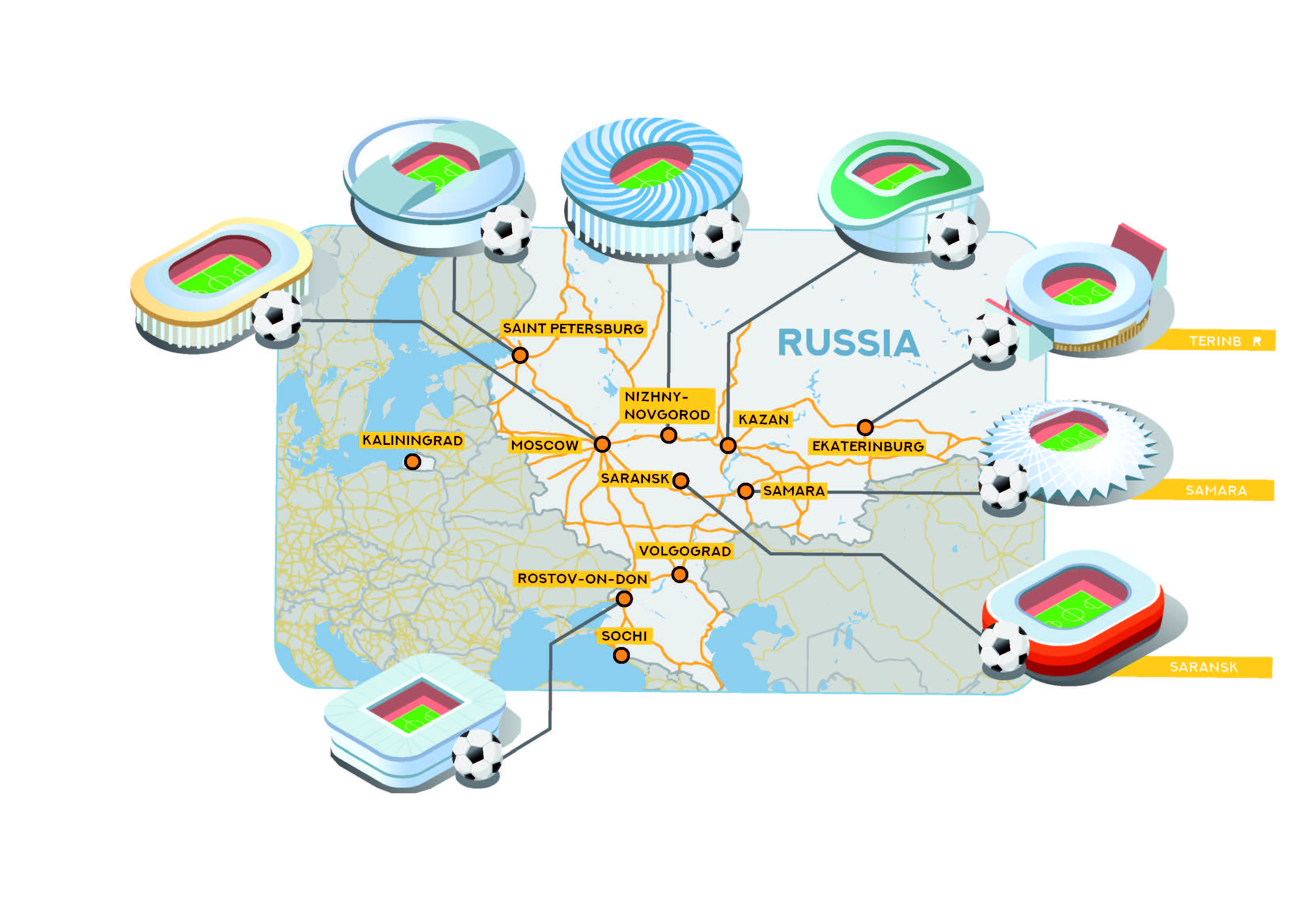

Wherever a sporting event offers so much excitement that it breaks down national borders and is shared on a global level, Mapei is there. And the Group is also there alongside the players, with research scientists from the Mapei Sport Centre, or as one of the main sponsors of the competition or as a supplier of products of excellence used to build the stadiums and arenas. And it is precisely in this latter role that Mapei is present at the 2018 FIFA World Cup held in Russia from the 14th of June until the 15th of July. 31 nations are taking part, as well as the host nation, the only team with an automatic qualification for the tournament. The matches are being played in 11 cities and 12 stadiums and the final is scheduled for the 15th of July at the Luzhniki Stadium in Moscow. The provisional list of candidate cities to host the 64 matches of the 2018 World Cup included 16 names, which had been whittled down to 11 once the final choice was made. The host cities are Moscow, St. Petersburg, Kaliningrad, Nizhny Novgorod, Kazan, Samara, Saransk, Volgograd, Rostov-on-Don, Sochi and Ekaterinburg. The matches in Moscow, the heart of the tournament, are played at two stadiums. The lowest capacity of the selected stadiums is 35,000 in Ekaterinburg, while the largest structure is the Luzhniki Stadium in Moscow. The average distance between the 12 stadiums hosting the matches is 600 km.

To organise the tournament, around 15 billion Euros have been invested (half of which from private investors) in work on the stadiums and infrastructures in and around the chosen cities. Some of the stadiums have been newly built while others have been completely renovated and modernised. In eight of the structures (Luzhniki Stadium, Samara Arena, Kazan Arena, the Mordovia Arena, Nizhny Novgorod Stadium, Rostov Arena, St. Petersburg Stadium and Ekaterinburg Arena) Mapei’s high-performance products have been used with great success to help overcome delicate problems encountered on site and to speed up the work.

Lužniki Stadium

2017 saw completion of the Luzhniki National Stadium in Moscow, which was built for the first time in 1956 by the Soviet government. The original stadium was demolished in 2013 to leave space for the new Luzhniki Stadium, which was then given a complete makeover for the 2018 World Cup. Mapei supplied products to repair the concrete structures in the areas adjacent to the pitch, where safety moats to prevent fans reaching the playing field were built at the foot of the spectator stands. MAPEGROUT HI-FLOW mortar was used to repair the concrete in this area. ULTRAPLAN ECO 20 self-levelling, ultra quick-hardening smoothing compound (which is manufactured and distributed on the Russian market by ZAO Mapei) was used for the substrates in the pedestrian areas inside the stadium. KERACOLOR FF mortar was then used to grout the joints in the porcelain tile covering. ADESILEX P7 adhesive, which is distributed on the Russian market by ZAO Mapei, was used to bond ceramic tiles in several internal service areas (toilettes, showers, etc.). This stadium will host the opening and closing ceremonies of the World Cup, as well as the first match.

Kazan Arena

The Kazan Arena was built in 2013, in the city of the same name in the Republic of Tatarstan, to host the home matches of Rubin Kazan’s team and for the 2013 Universiade. The design of the stadium represents a water lily and blends in perfectly with the urban fabric of the city. The structure has a capacity of 45,000. The substrates were waterproofed and protected with MAPELASTIC two-component, flexible cementitious mortar. To renovate the structure, the contractor used more than 5 tonnes of MAPEGROUT THIXOTROPIC fibre-reinforced, shrinkage-compensated mortar for repairing concrete, as well as MAPEGROUT HI-FLOW 10 ready-mixed mortar, which is manufactured and distributed on the Russian market by ZAO Mapei.

Mordovia Arena

Construction work on the Mordovia Arena started in 2010 in Saransk and was completed in 2017, in time for the 2018 World Cup. Once the tournament is over, the Mordovia Arena will become the new home ground of the city’s team, Mordovia, and its capacity will be reduced to 28,000 from its current 45,000, leaving space for other sports facilities. The stadium is shaped like a large bowl and is decorated in the city’s colours (red, orange and white). The design includes many metal structures to support high loads. This required the use of high-strength, shrinkage-compensated fluid mortars. To anchor the metal structures, the contractor used MAPEFILL and MAPEFILL 10 (the latter product is distributed on the Russian market by ZAO Mapei) mortars specifically designed for high precision anchoring of exposed structures, columns and joints in structures made from reinforced concrete. MAPEGROUT THIXOTROPIC fibre-reinforced, shrinkage-compensated mortar was also used in this complex.

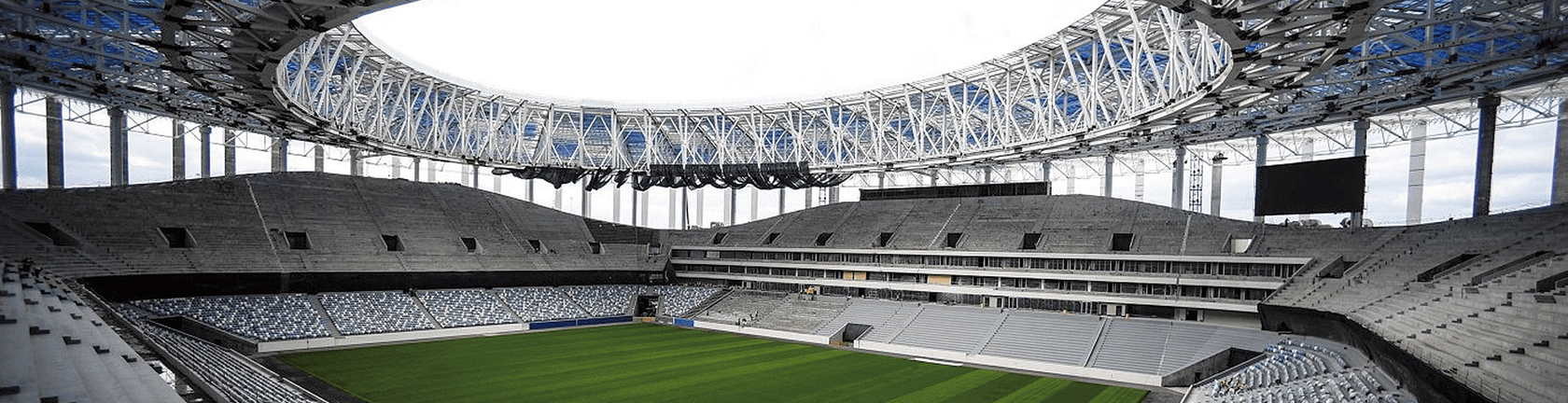

Nizhny Novgorod Stadium

The Nizhny Novgorod Stadium underwent important renovation work which significantly changed its look and increased its capacity to 45,000. It will be one of the most used stadiums during the 2018 World Cup. The design and colours (white and blue) of its structure represent the two elements which are symbols of the Volga region: the water and the wind. Stringent specifications for the quality of the monolithic structures and a tight work schedule during the particularly rigid winter months required special monitoring of the concrete production and the overall quality of the work. Rigorous testing was carried out to verify the resistance and strength of the concrete. Following these tests, the product chosen was MAPEGROUT THIXOTROPIC fibre-reinforced, compensated-shrinkage mortar, which was used to repair damaged concrete on both horizontal and vertical surfaces.

Rostov Arena

The Arena in Rostov-on-Don, one of the main cities in southern Russia, has an oval structure with an undulating roof covering the spectator stands, leaving the pitch open. The overall stability of the structure is guaranteed by the combined action of vertical diaphragms, horizontal floor slabs and other flooring elements. Mapei’s main contribution in the construction of this structure was the supply of MAPEKLEY EXTRA adhesive, a product available on the Russian market. It was used to install ceramic tiles in specified areas of the structure and was chosen for its excellent adhesion and high resistance to water and freezing weather conditions, in order to comply with FIFA regulations.

Samara Arena

Even though the Samara Arena is not the largest of the stadiums to host the 2018 World Cup, it is without a doubt one of the most original. The designers were inspired by the aerospace industry, which plays an important role in this city. The Samara Arena is a dome-shaped structure reaching a height of 60 m, with a hole in the centre which makes it look like a spaceship. Mapei supplied various products to repair concrete, such as MAPEGROUT THIXOTROPIC shrinkage-compensated, fibre-reinforced mortar and MAPEGROUT FAST-SET R4, a class R4, rapid-hardening, fibre-reinforced, compensated-shrinkage mortar distributed on the Russian market by ZAO Mapei. Special attention was given to repair work on the cracks in the reinforced concrete structure, which was carried out using EPOJET epoxy resin. The substrates were waterproofed and protected with MAPELASTIC two-component, flexible cementitious mortar.

Ekaterinburg Arena

The Central Stadium, or Ekaterinburg Arena, is located in the city of Ekaterinburg. The renovation project included increasing its capacity from 27,000 to 45,000 and conserving the historic façade of the structure, which is an official Russian Cultural and Heritage Site as an example of a public sports facility in Soviet neoclassical style. Because of the conformation of the stadium, it was difficult to find a suitable solution to increase its capacity without demolishing and rebuilding the spectator stands or raising the roof. It was decided, therefore, to construct external spectator stands behind the two goals, which will then be dismantled once the tournament is over. To strengthen the piles supporting the stadium’s imposing roof, a particularly mechanically strong and resistant product was required. The ideal solution was MAPEGROUT THIXOTROPIC, a shrinkage-compensated mortar characterised by its high level of adhesion to concrete and its excellent resistance to water.

St. Petersburg Stadium

The St. Petersburg Stadium is the most avant-garde sports facility ever built in Russia and stands out for its complete lack of pillars inside the structure, which allows for a higher capacity and an excellent view of the pitch from every seat. MAPEGROUT 430 fine-grained, fibre-reinforced, normal-setting thixotropic mortar was used to repair the concrete structures, which were then smoothed over with MONOFINISH one-component, normal-setting cementitious mortar. Before installing the stone flooring in the toilettes and shower cabins, the substrates were treated with PRIMER G synthetic resin primer in water dispersion. To form a perfectly flat surface, the substrates were then levelled with ULTRAPLAN and ULTRAPLAN ECO self-levelling compounds. Slabs of granite from the Urals were chosen for the floors and bonded with KERABOND T cementitious adhesive while joints were grouted with KERACOLOR FF and ULTRACOLOR PLUS mortars.

For further information see our Russia 2018 section .