Research at the service of major infrastructures

How a concrete repair product is created in the laboratory

How a concrete repair product is created in the laboratory

Repairs to the concrete of large-scale infrastructures has become an issue of primary importance as shown, unfortunately, on reports and bulletins issued by news outlets in recent years. Each structure in reinforced concrete starts interacting with the surrounding environment as soon as it has been constructed. Factors such as carbon dioxide, water, aggressive substances such as chlorides and sulphates, thermal stresses (freeze/thaw cycles), etc., along with possible design and construction errors, all lead to various forms of deterioration: efflorescence and liquids percolations, corrosion of reinforcement rods, cracks, detachment, etc. Repair work on concrete, therefore, is an operation that requires specific knowledge and skills, starting from an analysis of the causes of the deterioration, to defining the correct techniques for the intervention and choosing which types of products should be used.

Repair work on concrete is covered by European standard EN 1504, which is sub-divided into different sections that define the main chemical/physical and performance properties of products used for repair work.

In order to guarantee the structure fulfils its expected service life after it has been repaired, apart from complying with the properties specified by current standards, the material used for the repair work must also satisfy the principle of durability.

Mapei has always been very sensitive to this problem and, through our Research & Development laboratories, we are constantly striving to improve the durability of concrete with our products.

How is a Mapei product for concrete repair developed?

Formulating a repair product is a process that requires time and study both in the definition of the composition and in the determination of the characteristics, as well as in the subsequent evaluation. The initial phase focus on reproducing various formulates in order to choose the appropriate ingredients in terms of quality and environmental sustainability, and then combining them to obtain a mix that is functional from every perspective. The formulate must also meet all the requirements in terms of chemical, physical and mechanical properties specified by current standards as well as specific requirements necessary for its use. Formulates are then evaluated according to various test methods to find out the most suitable one.

Focus on durability

As mentioned previously, it is fundamental that products for repair work are durable over time. In fact, particular attention is dedicated to studying the main characteristics in terms of durability: a good level of adhesion to guarantee the monolithic nature of the existing structure, dimensional stability to contain shrinkage that causes cracking, protection against ingress of aggressive agents, etc.

To verify and guarantee how effective they really are, products are studied by simulating the problems that can occur outdoors under real service conditions, reproducing the various types of stress they have to withstand.

To evaluate the quality of Mapei formulates accurately, we are also very careful about the choice of test methods to be used, favouring those methods that guarantee good repeatability of results, but which are also able to simulate as closely as possible real exposure conditions. For many years Mapei has been highly dedicated and committed to the development of standards by participating in work groups with Italian and international organisations and associations. Sometimes standards are incomplete and/or propose test methods impractical and not particularly selective. Thanks to our extensive experience we can help improve these standards and even bring them in line with the latest market demands.

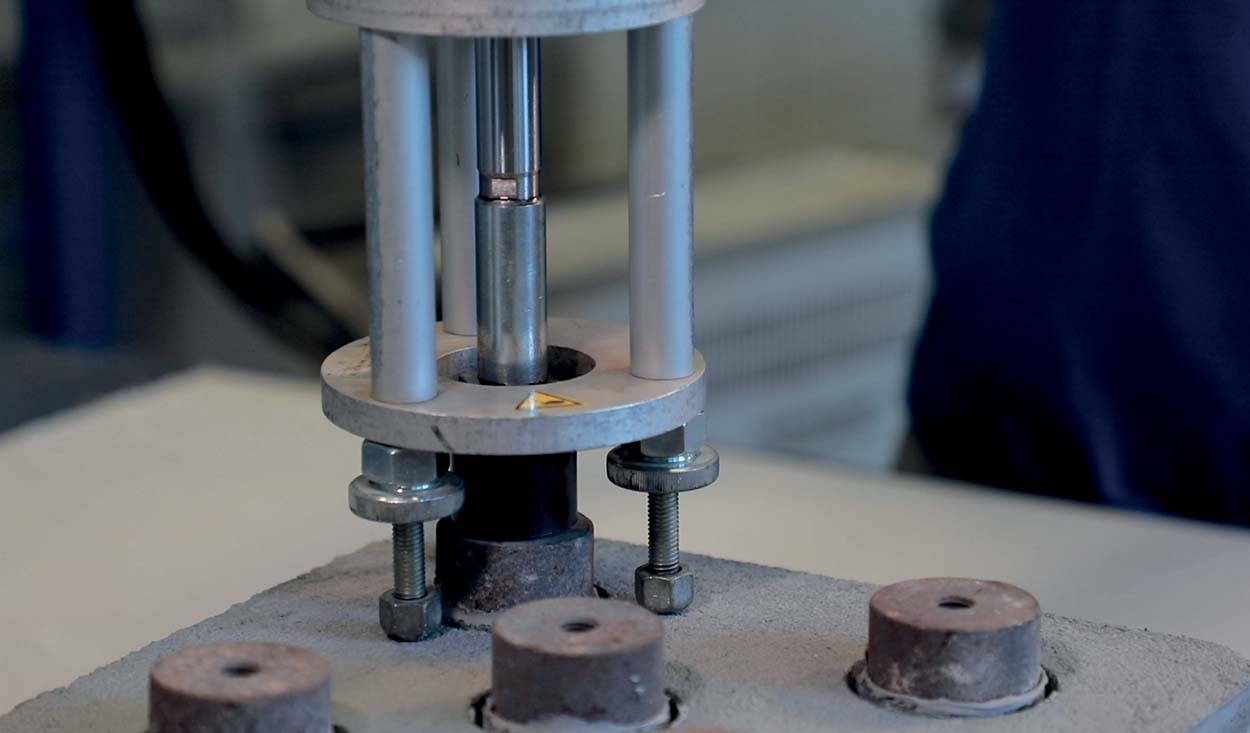

Durability cannot be assessed through laboratory tests alone on small quantities of a product which is why, with the help of Mapei Technical Services team, in the test areas of our laboratories we simulate the real types of product mixes and the real application phases like in job sites. Then we study the durability of these artifacts over time by means of adhesion tests, by monitoring the dimensional stability and by evaluating carbonation and/or the penetration of aggressive agents. Thanks to this approach we are able to finally arrive at product formulations with guaranteed properties even in the most critical service conditions.

Another aspect that needs to be taken into consideration is the economic viability of a product. A competitive product from an economic perspective, however, is not always a guarantee of quality: the challenge for Mapei is to find the right balance between the economic viability of a material and its performance qualities, which have always been a trademark of our products. Once the development process of a product has been completed, we also work with accredited testing institutes to certify and guarantee its performance properties to further confirm what has already been studied and tested.

Complete product systems

Up until this point, we have described how a product used for repair work is formulated in the Mapei R&D Laboratories.

From our point of view, however, to talk about a product alone is not exhaustive: sometimes a single product is not sufficient. For really effective, durable repair work we believe it is fundamental to recommend a product system that provides protection for the reinforcement rods, repairs and restores concrete using structural and non-structural products and, above all, protects the concrete, a fundamental aspect in order to guarantee the durability of structures.

This aspect, therefore, must also be considered in the case of new constructions to ensure they fulfil their designed service life.

So, our activity is not limited to formulating and studying a single product; it involves the study, research and evaluation of the benefits of repair work carried out using complete product systems.

The final aspect, and one which should never be overlooked, is how the products mentioned above are actually applied. To get the best results from repair work the way they are applied on site is fundamental: a high-quality product applied incorrectly could have a more negative influence on the final result of repair work than a poor-quality product applied in the correct way. This is why the work carried out in our laboratories includes also the drafting of technical documentation (technical data sheets, application manuals, operating instructions, etc.) in order to provide all the information and details required for the correct use of a product.