Repair work on sewer pipes

From the Mapei laboratories: specific products for any type of degradation.

From the Mapei laboratories: specific products for any type of degradation.

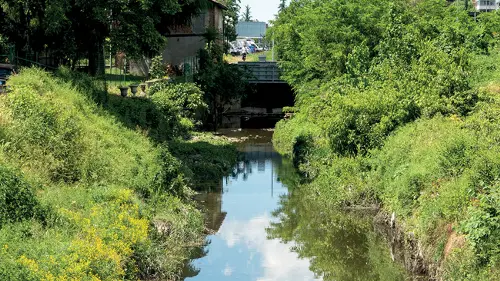

Sewer systems are essential infrastructures in order for urban areas to function correctly by ensuring that wastewater is transported and treated. They are made up of a network of masonry and concrete channels and pipes, running mainly underground. They often have no protective coatings or covering and are at risk, therefore, of degradation due to the aggressive nature of the water flowing through them. Apart from chemical-type degradation caused by organic and inorganic substances dissolved in the water, they are also at risk of physical degradation from mechanical loads and stresses, such as variations in traffic conditions on the road network above the sewers or the connection of new channels or pipes, increased flow rates and wear due to the abrasive action of debris. Damage deriving from the degradation of these infrastructures can have significant consequences for the environment, such as indirect contamination of the ground and pollution to water flowing both above ground and below ground level.

Periodic repairs are required, therefore, to guarantee they function correctly and ensure they have an adequate "service life". The Mapei Research laboratories also dedicate their efforts to the development of bespoke products for repairs work on sewer systems. In order to formulate a repair product that is effective, first and foremost the aggressiveness of the environment needs to be defined, based on the type of water discharged into the pipes.

In compliance with Italian Decree 152/06, wastewater can be divided into three categories according to its origin: domestic waste water, industrial waste water, and urban waste water. These different types of water may be channelled into the same pipes or kept separate, depending on the layout of the sewer system installed in each area. So, for every repair intervention, it is fundamental to define the level of aggressiveness of the water on the basis of analyses. Waste water can be considered slightly aggressive, such as rainwater for example, rather than highly aggressive, such as from human metabolism and domestic activities. According to the level of aggressiveness, the minimum requirements a product used for repair work needs to meet must be defined.

Slightly aggressive water will always contain low concentrations of organic and inorganic micro-pollutants, such as detergents, hydrocarbons, oil, chlorides, sulphates and nitrates, as well as other substances that attack the cementitious paste of traditional products. However, products containing special hydraulic binders can be developed that have a good level of durability thanks to their chemical composition and physical-mechanical characteristics.

PRODUCTS FOR HIGHLY AGGRESSIVE WATER

In the case of channels and pipes carrying highly aggressive water, such as water containing a high concentration of organic material from lavatories, the main cause of degradation is the presence of sulphuric acid (Fig. 1) originating from bacteria in raw sewage by means of aerobic and anaerobic processes that quickly dissolve the cementitious paste and deteriorate the matrix of mortar and concrete. In these kinds of environment, products that have passed specific acid-resistance tests need to be used. Mortars designed for coating these types of channels and pipes are covered by DIN 19573 standard, which classifies them according to their level of chemical resistance with an alfa-numeric code such as XWW4, which corresponds to a product with the highest level of resistance to corrosion caused by exposure to biogenic sulphuric acid. Mapei recently completed a research project to develop a new product called PLANITOP SEWAMENT XWW4, an addition to other products already available for this type of application. Specifications to achieve XWW4 classification are extremely severe: the degree of degradation is evaluated after immersion in sulphuric acid in environments at different pH levels (pH 0 and pH 1). Determining its residual compressive strength (that is, its performance properties after immersion in an aggressive environment compared with the same product without conditioning) indicates up to what point the structure of the material has deteriorated and enables the amount of corrosion due to the effect of the acid to be defined. In Figure 2, we can see the drastic change in the visual aspect and the significant reduction in the dimensions of ordinary mortar, after being immersed in acid, compared with XWW4 class mortar, which remains almost unchanged.

The graph in Figure 3 compares the compressive strength of the two mortars after immersion in water and their compressive strength after immersion in acid: the significant reduction in compressive strength of the ordinary mortar confirms the high amount of corrosion observed during the visual inspection and its unsuitability for use in repair work on sewer systems. The XWW4 class mortar, on the other hand, confirms a high level of residual compressive strength (> 55% as specified by DIN standards) and a low amount of corrosion.

Analysis through an SEM scanning electron microscope (Figure 4) confirms the high resistance to sulphuric acid of the XWW4 mortar compared with ordinary mortar, in which cracks are clearly visible.

Defining a high-performance product for repairing sewer systems, even in the most severe exposure conditions, is the result of thorough research work through careful, precise experimentation, besides selecting and optimising the most appropriate type of binder and aggregate in order to balance material quality and cost-effectiveness.

.jpg?sfvrsn=fe57538e_5)

.jpg?sfvrsn=657538e_5)

.jpg?sfvrsn=c57538e_5)

.jpg?sfvrsn=f957538e_5)