Redevelopment of schools: the quest for the right compromise

Giulio Morandini, Mapei Group’s Corporate Director - Building Line, discusses the issue.

Giulio Morandini, Mapei Group’s Corporate Director - Building Line, discusses the issue.

What does the redevelopment of a complex building such as a school entail?

Redeveloping a complex building such as a school inevitably means having to compromise between upgrading its actual structural capacity and maintaining certain architectonic standards. Various techniques can be adopted with this type of intervention; they are, however, invasive techniques that may also compromise the overall use of the internal spaces. This is why upgrading a structure generally means having to find solutions that safeguard the global functionality of the entire school. And this is undoubtedly one of the most important objectives with this type of intervention. Another important factor to take into consideration is how to schedule the work. It should be carried out when the school is closed because it is almost impossible to work if the school is open.

In general, what are the most common problems with this type of building?

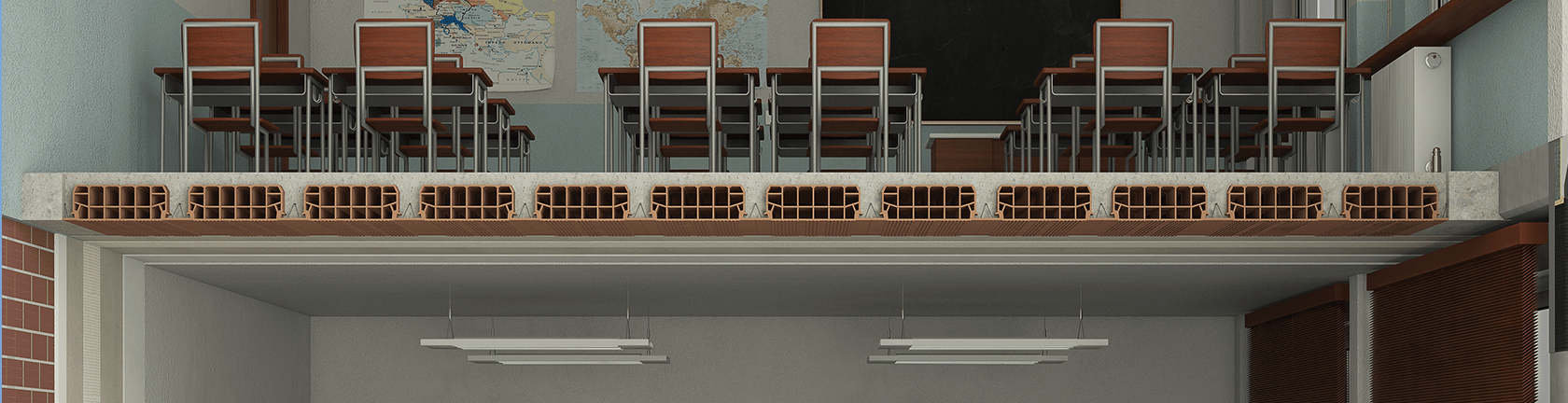

A lot of schools have been around for decades and are certainly not designed according to anti-seismic criteria. This means you very often find that floor slabs are not rigid enough to distribute loads in the event of seismic activity. This is a real problem, also because floor slabs often have a very large span and, due to their very nature, they are particularly susceptible to a certain amount of flexibility. Floors need to be rigid and, the more rigid they are, the better. So we need to find rapid solutions that enable us to make them more rigid without having too much of an impact on their thickness. If you change the thickness of floors, you then find yourself having to change windowsills, doorsills and stairs.

A second problem is given by the fact that, when structures are made from reinforced concrete, the beams and pillars usually have an insufficient amount of stirrups. In the event of seismic activity, this means structures are unable to deform sufficiently to allow seismic energy to be dissipated. One of the techniques adopted, which is very effective and only slightly invasive, is the use of FRP (Fiber Reinforced Polymers). The technique in question allows any lack of stirrups to be integrated using external binding. In simple terms: it is like putting a series of “sticking plasters” around a column, which is the equivalent of having a lot of stirrups inside an element, thereby increasing the deformation capacity of the actual column in the event of seismic activity.

When local authorities have to plan work on school building stock, they are almost always faced with the problem of budgetary constraints. What solutions does Mapei propose?

Mapei has developed three solutions with works on school buildings in mind.

The first one is MAPEWRAP SYSTEM which overcomes the lack of stirrups in columns and slabs.

The second one is PLANITOP HPC FLOOR, a special mortar applied in very thin layers to strengthen floor slabs without changing their total thickness.

The third solution regards dividing and buffer walls. Very often, in the event of seismic activity, dividing and buffer walls can become detached and overturn. During an earthquake, people run out of classrooms and go into the corridors and falling partition walls can obstruct escape routes. A few years ago Mapei developed MAPEWRAP EQ SYSTEM specifically to increase the time available to evacuate buildings. By applying this system on walls, non-structural walls can be kept under control and we can prevent them from tipping over or exploding during earthquakes. The first ever application of MAPEWRAP EQ SYSTEM was, indeed, in a school and, to be more precise, in the Teresio Olivelli Technical Commercial Institute in Darfo Boario Terme (Province of Brescia, Northern Italy).

The real advantage of the three mentioned systems is that they can be used either together or on their own. This allows designers and local authorities to consider their costs and benefits. If there is a limited budget and the school is particularly deficient in terms of seismic vulnerability, then a more precise evaluation needs to be carried out, increasing its anti-seismic protection and working on the most sensitive areas; focusing only on certain points of the structure which, during an earthquake, appear to be the most dangerous. To put it briefly: rather than extend the intervention to the whole of the building, you carry out work in targeted, localised areas.

What is the advantage of carrying out localised work?

The advantage of localised work using one or all three of the systems mentioned previously is they don’t modify the global behaviour of the structure. Opting for more traditional techniques, on the other hand, modifies the rigidity of a structure and, in the event of an earthquake, creates imbalances in the whole of the structure, including where work hasn’t been carried out. If we adopt localised interventions using Mapei systems – only slightly invasive, very light, rapid to apply and with a high return in terms of performance – it is like putting lots of sticking plasters but only where there are scratches, rather than opting for a plaster cast. It is better to carry out targeted, localised redevelopment work with good global performance characteristics to inhibit the main collapse mechanisms rather than a more widespread intervention on the entire structure.

A country’s school building stock is a very important sector and there is a costant need to plan upgrading and structural development work. What is it like to discuss these issues with local authorities?

With local councils, particularly the smaller ones, the main contact is a designer, who is always an external figure. To make local authorities more aware of the issues, Mapei Technical Services are often invited to meetings to provide support for the designers and to offer their opinion or advice on the most appropriate systems to help overcome problems. Or, again when invited by the designer, if a set budget has been allocated, we study and design a bespoke solution that is able to balance costs and benefits. And obviously, apart from carrying out site surveys to analyse problems, our Technical Services Department always – and when I say always, I mean always! – provides support for the Director of Works during the actual application work. For instance, in the last few years, thanks to the release of the Schools Plan, the Italian Government and local authorities have become more aware of and more sensitive to the structural condition of Italian schools and I believe this will always be on the increase.

ANTI-SEISMIC AND STRUCTURAL STRENGTHENING SYSTEMS

Mapei offers innovative systems for structurally strengthening schools which ensure: simple and quick application; high durability; no increase in the masses involved in the intervention, hence no modification to the stiffness of the structure. Mapei also offer systems to improve and upgrade the anti-seismic protection of our school building stock.

MAPEWRAP EQ SYSTEM

Patented, certified system developed to make buildings safer, such as by preventing dividing and buffer walls, as well as ceilings from collapsing.

The system is made up of MAPEWRAP EQ NET bi-directional glass fibre reinforcing fabric that forms a perfect bond with rendered substrates by applying MAPEWRAP EQ adhesive, a polyurethane adhesive in water dispersion.

This system is tested and certified; unobtrusive, compact, quick and easy to install. It can be applied on existing plaster and has very low emission level of VOC (Volatile Organic Compounds).

PLANITOP HPC (HIGH PERFORMANCE MICRO-CONCRETE) TECHNOLOGY

An exclusive strengthening system made up of micro-concrete with very high compressive strength, high ductility and the capacity to absorb high fracture loads. This product is a fibre-reinforced concrete that contains a high percentage of steel fibres which, by exploiting their residual tensile strength, increase the overall load-bearing capacity and ductility of structures (two properties which are fundamental in areas at risk of seismic activity). This technology consists of a special formula, PLANITOP HPC, developed to strengthen load-bearing structures (slabs, pillars, joints) with a layer of compact cladding (1.5-3 cm thick) and is used alongside PLANITOP HPC FLOOR, which was developed to strengthen the outer face of concrete, brick/cement and wooden floors by applying a strengthened, compact added layer (1.5-2.5 cm thick) without any further reinforcement.

MAPEI FRG SYSTEM

The various systems that form the macro-family of FRG (Fibre Reinforced Grout) are made up of an inorganic matrix (mortar) in which strengthening fibres in the form of mesh are embedded. FRG systems may be divided into the following families: FRCM (Fibre Reinforced Cementitious Matrix) and CRM (Composite Reinforced Mortar) systems.

FRCM systems are made up of special fibre-reinforced mortars applied in low thickness layers (around 1-1.5 cm) in combination with various types of strengthening mesh (made from A.R. (alkali-resistant) glass, basalt or carbon fibre). These systems allow the mass and rigidity of the strengthening package to be reduced effectively while significantly increasing its mechanical properties.

CRM systems are made up of mortars suitable for application in layers up to 3-4 cm thick, so they also cover the surface of uneven (masonry, combined with A.R. (alkali-resistant) glass fibre mesh. Because of the thickness applied, the system needs to be connected mechanically to the masonry with glass fibre connectors. The aim of this technology is to improve the mechanical properties of masonry and increase the level of collaboration between the elements making up the masonry.

FRCM technology can also be used for local intervention to ensure anti-tipping protection of non-structural and partition walls

MAPEI FRP SYSTEM

Structural strengthening system comprising high strength and very high strength fibres and epoxy matrixes specially formulated for the repair and static and seismic upgrading of structures made from normal, pre-stressed and reinforced concrete, steel, masonry or wood. There are various types of fibres that characterise this type of structural composite: carbon, glass, steel and basalt. This system increases the performance characteristics of structures by increasing their strength and ductility.