Rector's Palace in Zadar

Numerous Mapei solutions have helped the Rector's Palace to shine with new splendour.

Special mortars and finishes and have given the walls of a famous Croatian historical palace new life. The historic terrazzo floor has been treated with a sound Mapei cement-based cycle which could offer the closest effect to the original historical appearance. Many more Mapei solutions to preserve this Croatian heritage.

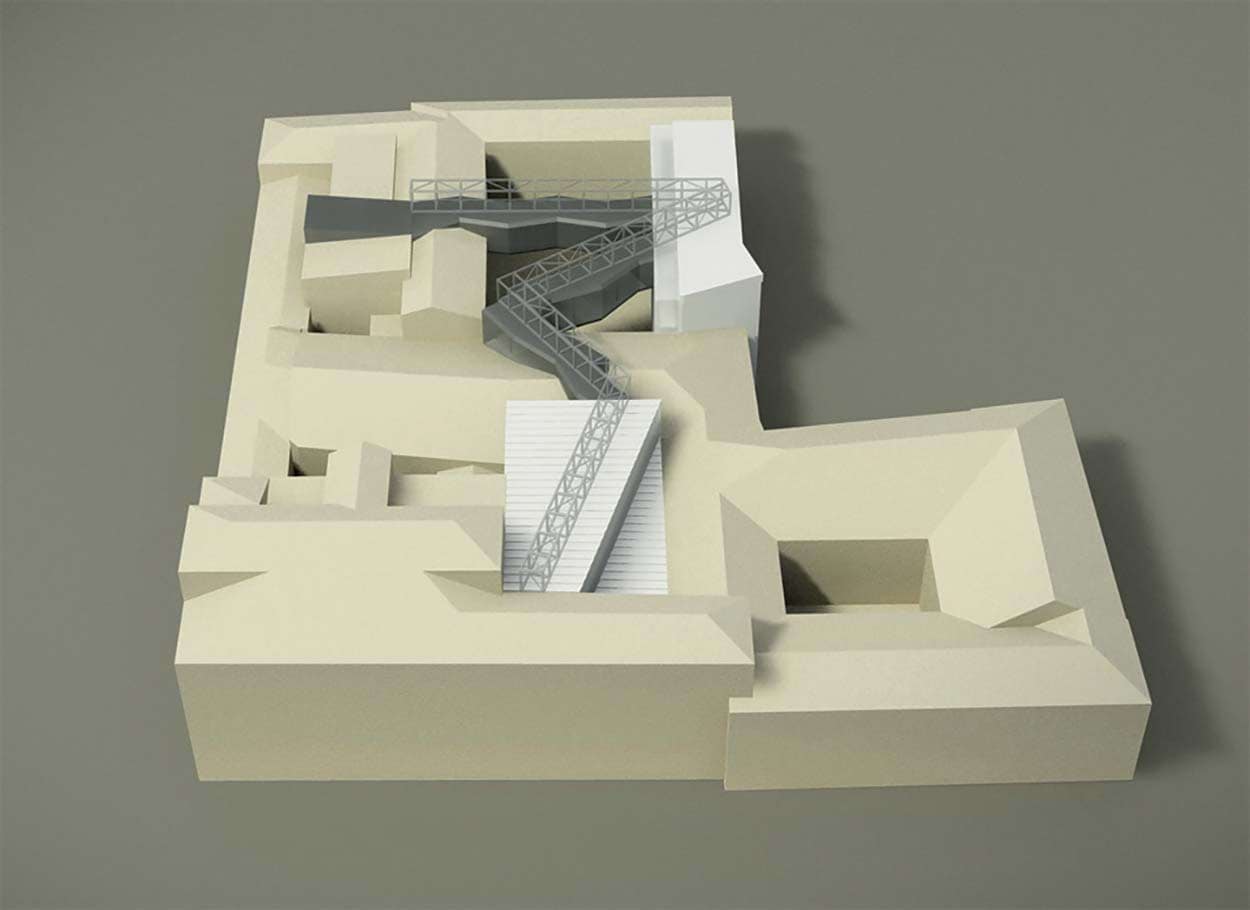

The recently restored historical palace in Zadar was, historically, a favourite gathering place of Zadar’s residents. The Rector's Palace was first mentioned in a 1288 document where it was called the Municipal Palace. Archaeological research works revealed parts of the building were from the Roman and Late Antique period - a 1278 document suggests that the apartment was rented to the rector.

The Palace’s large hall served many different purposes over the years - during the Roman period the hall acted as the Town Hall housing the City council, during the 16th century it served as a courtroom, 18th century a theatre,19th century as a playground and entertainment hall and during the 20th century as a concert hall. The Palace’s continuous change in purpose has over the years, been reflected in the Palace’s name - Municipal, Judicial, Governor's, Government, Provincial Palace, and House of Culture. The palace was completely renovated in the 16th. As it was expanded, repaired and upgraded, it also gained new stylistic features.

In 1804, the palace was restored to the designs of the classicistic architect Frane Zavore. The renovation completely changed the look of the northern façade and subjected it to new technical and aesthetic achievements in the construction, systematic and symmetrical spirit of classicism. The restoration was completed in 1807 and was the first accomplished classicistic project in Zadar. A further restoration occurred at the end of the 19th century, when the west façade and its surroundings were significantly altered.

For many years, the Rector’s Palace refined the cultural life of the city of Zadar through its multiple functions. The Palace contained the city library, a music and ballet school, a concert hall, Zadar radio station and a mixed choir, Petar Zoranić, as well as the girls' choir Juraj Baraković. During the Homeland War in 1991, the Rector's Palace was shelled out from of one of the city's barracks, causing great damage and significantly disrupting the statics of the building - enough to become unusable. The first demanding static and building renovation of the post-war reconstruction began in 1999.

SIGNIFICANT CULTURAL AND HISTORICAL COMPLEX

In December 2011, architects Letilović and Pedišić won the prestigious prize of the Association of Croatian Architects Bernardo Bernardi for the architectural solution of the Provisional Exhibition Hall, Rector’s Palace in Zadar, in the category of the most successful achievement in the area of design and interior decoration in 2011 in Croatia. In 2014 began the implementation of the Project Reconstruction and tourist valorisation of cultural and historical complex of the Rector’s Palace financed by the Structural Funds’ grant of the European Union. At the end of last year, reconstruction work was completed, and the Rector’s Palace had a new life.

In the preparation and realization of the Project, the Technical Department of the Mapei Croatia participated with proposals for solutions for various types of works; from the renovation of capillary damp and the waterproofing of the facility through the renovation of masonry structures with injection mixtures and the installation of floor systems to the installation of the dehumidifying and finishing decorative render systems. Mapei's systems and solutions have been accepted by both the designer and the contractor and have become part preserving of this fascinating historic building.

COMPLETE RESTORATION WITH A VAPOUR PERMEABLE SYSTEM

In order to prepare the substrate, all layers of the existing render were removed to the brick or stone itself, unbound and slightly bound materials between joints were also removed. Afterwards all surfaces were washed with low pressure water jets, removing saltpetre on the surface and any remaining loose parts and dust. This procedure was repeated several times until the substrate cleanliness was achieved. The joints were filled with render based on natural hydraulic lime and Eco-Pozzolan MAPE-ANTIQUE INTONACO NHL. Before application, the substrate was saturated with water in order to prevent substrate absorbing the water from the render. The excess water evaporated so the substrate remained saturated, with no visible droplets of water on the surface. MAPE-ANTIQUE INTONACO NHL was applied with trowel to the substrate with light pressure between the masonry elements to improve adhesion. The excess of render was removed immediately after installation, including constructive masonry elements and joints were cleaned with a damp sponge and brush.

APPLICATION OF A VAPOUR-PERMEABLE RENDER

The inside surfaces of the masonry and part of the façade walls were treated with a vapour-permeable render from the Poromap line. Before the application of a vapour-permeable render based on natural hydraulic lime and Eco-Pozzolan, it was necessary to saturate the substrate with water in order to prevent absorbing the water from the render. A salt-resistant, underlay mortar POROMAP RINZAFFO MACCHINA was applied to the prepared wall. The underlay mortar had been applied before the dehumidifying and insulating render POROMAP INTONACO MACCHINA in a thickness of 5 mm. Thereafter, with a rendering machine, in the thickness of 20 - 30 mm was applied POROMAP INTONACO MACCHINA, a ready-mixed powdered mortar for dehumidifying and insulating render used for renovating stone and brick masonry deteriorated by the presence of damp. The finishing fine granulation mortar POROMAP FINITURA was applied by hand to the preformed POROMAP INTONACO MACCHINA layer. Before applying mortar POROMAP FINITURA the bottom layer of render with a rougher texture had been well-washed with water and the excess water was eliminated.

FINISHING COAT

On the cured layers of the vapour-permeable render, a coat of highly transpirant silicate based primer SILEXCOLOR PRIMER was applied using a roller over the entire surface of the wall in order to uniform the absorption of the substrate. The walls were finally painted with a high-permeable and water-repellent paint on silicate basis SILEXCOLOR PAINT in two coats.

A COMBINATION OF HISTORY AND CONTEMPORARY FLOOR SOLUTIONS

The designer's request was to unite the historical spirit and use modern flooring solutions in order to retain its historical influences whilst adding 21st century style to reflect today’s world within the Rector’s Palace. For this reason, a terrazzo floor system was installed in the exhibition halls on the ground floor of the building and a polyurethane floor systems was installed in communication spaces and bathrooms. As a solution for the terrazzo flooring system, there was proposed, chosen and realized the solution with the ULTRATOP SYSTEM “terrazzo alla Veneziana” effect, which is the closest to the appearance of the historic terrazzo floor that was found in the Rector’s Palace.

This system is characterized by extremely high resistance to abrasion and mechanical damage, and the installation itself must be carried out on the appropriately prepared substrate. Therefore, the Technical Department of Mapei Croatia provided all the necessary support in designing and creating a substrate screed in order to make it meet the requirements for the installation of the ULTRATOP SYSTEM, “terrazzo alla Veneziana” effect. The greatest peculiarity of this system was obtained by adding agregates and mixing them both in terms of color and size. In that way there has been achieved a singular and unique visual effect.

PERFORMANCE OF THE ULTRATOP SYSTEM SYSTEM "TERRAZZO ALLA VENEZIANA" EFFECT

This ULTRATOP SYSTEM was completed on pre-made cementitious screeds with a compressive strength of 25 MPa, which was first processed with the diamond grinding to obtain an adequate adhesion of 1.5 MPa. To the so prepared substrate was applied the epoxy primer PRIMER SN, which was broadcast until full saturation with quartz sand QUARTZ 1,2. After the primer had been fully bonded, the excess of the quartz sand was removed and a coat of epoxy binder as a primer MAPEFLOOR I 910 was applied. While the product was still fresh, a MAPEFLOOR I 910 binder and a natural aggregate in the ratio of approximately 1 : 20 was applied. After the so prepared substrate was completely dried (24 hours), ULTRATOP was applied. In order to efficiently and effectively complete the smoothing works, the mixture was applied uniformly, making sure that all the voids between the aggregates were completely filled. Three days after the application of the mixture, the grinding and polishing process began to obtain a perfectly smooth and glossy surface resemble the floor coverings made on the model of Venetian Terrazzo. After finishing, a protective coat MAPECRETE STAIN PROTECTION, was applied.

POLYURETHANE FLOORS FOR COMMUNICATION SPACES AND BATHROOMS

A new system of polyurethane floors MAPEFLOOR COMFORT SYSTEM AR was installed in the communications corridors and bathrooms. These rooms are characterized by an excellent level of comfort underfoot, high resistance to mechanical aggression, water resistance and low emission of volatile organic compounds. It is exceptionally easy to maintain, making it ideal for use in kindergartens, schools, museums, restaurants and residential areas. The special feature of the system's installation at the Rector's Palace's facility was that the system was installed on a dry screed made of fiber plaster boards. Primer PRIMER SN was first applied to the board and then 150 grams weight fiber glass mesh MAPENET 150 was inserted into the first coating layer. After the first coat has dried, another coat of PRIMER SN was applied and after its drying, it was broadcast by quartz QUARTZ 0.5 mm. On the prepared substrate the aromatic polyurethane resin MAPEFLOOR PU 460 was applied in thickness of 2 mm. Once the resin has dried, the MAPEFLOOR FINISH 58 W coloured top coat was applied. The evacuation areas were coated with the anti-dust epoxy system MAPECOAT I 620 W to provide the surface to be easily maintained. MAPECOAT I 620 W is a two component epoxy coating in water dispersion, with excellent abrasion resistance. It is suitable for low-load spaces.

WATERPROOFING OF THE EXTERIOR WALLS OF THE PALACE

In addition to the waterproofing of the sanitations with the Mapelastic system, the waterproofing of the external walls also had to be solved. The walls along the southwestern façade of the Rector's Palace, north-west façade of Proveditor´s Palace (façades in the park), and part of the façade toward the atrium of Proveditor's Palace on the outside were damp. The capillary damp was solved by injection, it was still necessary to protect the wall approximately to half height of the foundation - that is up to about 50 cm of foundation height. After removing the existing render, treating joints, injecting and capillary damp ceasing, the joints had to be filled and the wall levelled with a high-quality cement-free mortar MAPE-ANTIQUE STRUTTURALE NHL made of natural lime and Eco-Pozzolan. The wall was waterproofed with osmotic cement mortar PLANISEAL 88 applied by brush in three coats. The wall was treated up to a height of 1 m above the finishing elevation of the ground providing a suitable base for finishing the walls.

BEING A PART OF HISTORY

In our Research & Development Laboratories, we continually improve new products and systems to help restore the most demanding historical buildings. One of these was certainly the Rector's Palace in Zadar, which with its complexity, presented to us a challenge that we Mapei gladly accepted. The strengths of Mapei’s R&D facilities enabled Mapei to respond to the project demands by providing innovative solutions. Being part of history is a great honor for Mapei, and the feeling that we have embedded ourselves in such valuable heritage is invaluable.