RE-CON AGG for the concrete mixes used SS16 “Adriatic" trunk road

RE-CON AGG 200 admixture by Mapei was used in the works to widen the stretch of the SS16 “Adriatic” trunk road in Central Italy

A concrete specialist working for one of the biggest Italian concrete manufacturers tells us about the advantages of using RE-CON AGG 200 to enhance the concrete performances

In the summer of 2021 work started to widen the stretch of the SS16 “Adriatic” trunk road between Falconara and Torrette di Ancona in the Central-eastern part of Italy. The work was commissioned by Anas (the company that manages Italy’s trunk road and motorway network) with an investment of 250 million Euros and will result in the doubling in the width of the road to four lanes along a 7.2 km long stretch between the junction with the SS76 trunk road at Falconara and the Torrette exit. Work should take around 3 years and includes the construction of a new carriageway alongside the existing one (which will also be upgraded to match the characteristics of the new carriageway), the construction of new tunnels and viaducts, upgrading of the existing tunnels, replacement of the road deck of one of the existing viaducts and the demolition of four viaducts.

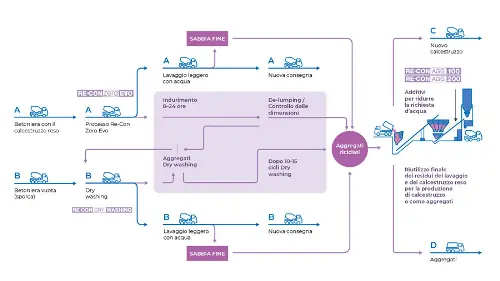

Mapei has already taken part in the work with the supply of 63,500 litres of RE-CON AGG 200 admixture, which was used during the first few months only to mitigate the effects of the high content of silt and clay fines in the sand, which would have had a negative influence on the strength and workability of the concrete mixes used.

RE-CON AGG 200 is a modified acrylic polymer-based admixture in water solution and has the capacity to disperse cement granules very efficiently and control the hydration process of the cement. It may be used in combination with clayey sand or other aggregates with high absorption to reduce the total amount of water employed and to achieve high mechanical properties at the hardened state.

The admixture was added to the two concrete mixes from Calcestruzzi SpA (part of the HeidelbergCement Group) used in the project. Each mix was of class S4 with a workability time of 90 minutes, but with different compressive strength classes (Rck 40 and Rck 30), and use of the admixture will certainly be extended throughout the duration of the work to complete the new road.

What were the main challenges with this project regarding the formulation of the two concrete mixes?

Which raw materials were used? And what, in particular, led to the use of clayey sand?

What part did Mapei admixtures play in the formulation of the mixes?

RE-CON AGG 200 enabled us to significantly reduce the amount of mixing water to achieve the mechanical properties required and to maintain their workability class for 90 minutes without any particular problems. RE-CON AGG 200 also enabled us to limit the development of air in the mixes, something that tends to happen with admixtures from our competitors.

Find out more about Mapei solutions for the concrete industry at: https://www.mapei.com/cis/en/home-page