Quality and safety without compromise: a new tool for checking the water/cement ratio in fresh concrete

To ensure a reliable and safe method for checking the water/cement ratio (w/c) in fresh concrete, Mapei R&D laboratories have recently adopted an innovative tool

Water/cement ratio is crucial for ensuring the strength and durability of structures. A study carried out Mapei Research & Development laboratories compares the new SONO WZ instrument with traditional methods, such as microwave drying and the UNI 11201:2017 standard. Statistical analysis shows that SONO WZ provides accurate and reliable w/c ratio measurements, minimizing human error and reducing dispersion. This led to the adoption of SONO WZ at Mapei R&D laboratories as an effective and safe tool for assessing concrete quality.

Microwave oven versus SONO WZ

STATISTICA software (TIBCO, Santa Clara USA) has been used to statistically process the data, in particular Gauss curve and Line Plot WLS have been chosen.

Gauss curve analysis allows to highlight the differences between the two methodologies, showing the data dispersion with respect to the target datum through the standard deviation.

Graphic analyses are reported as follows:

- Gauss curve for difference in water content: ∆= observed water – mix water (target)

- Gauss curve for difference in w/c ratio, considering the cement content in the target

- Gauss curve for the percentage deviation of w/c with respect to the target w/c

Gauss curve of the SONO WZ (red line) shows lower standard deviation than that obtained with the microwave oven (blue line).

W/c ratios are calculated on the basis of the water content determined by the two methods. The standard deviation of the obtained w/c, with respect to the target value, is lower for the SONO WZ than the values obtained with microwave oven. Moreover, the SONO WZ standard deviation is lower than 0.02, which is the tolerance value reported in the Work Specifications.

The percentage deviation of w/c with respect to the target w/c confirms lower values for SONO WZ.

Uni 11201 VS. SONO WZ

The second part of the present work concerns the application of UNI 11201:2017 – Test of fresh concrete - determination of water content, which defines how to determine the water content in fresh concrete by drying it through gas stove.

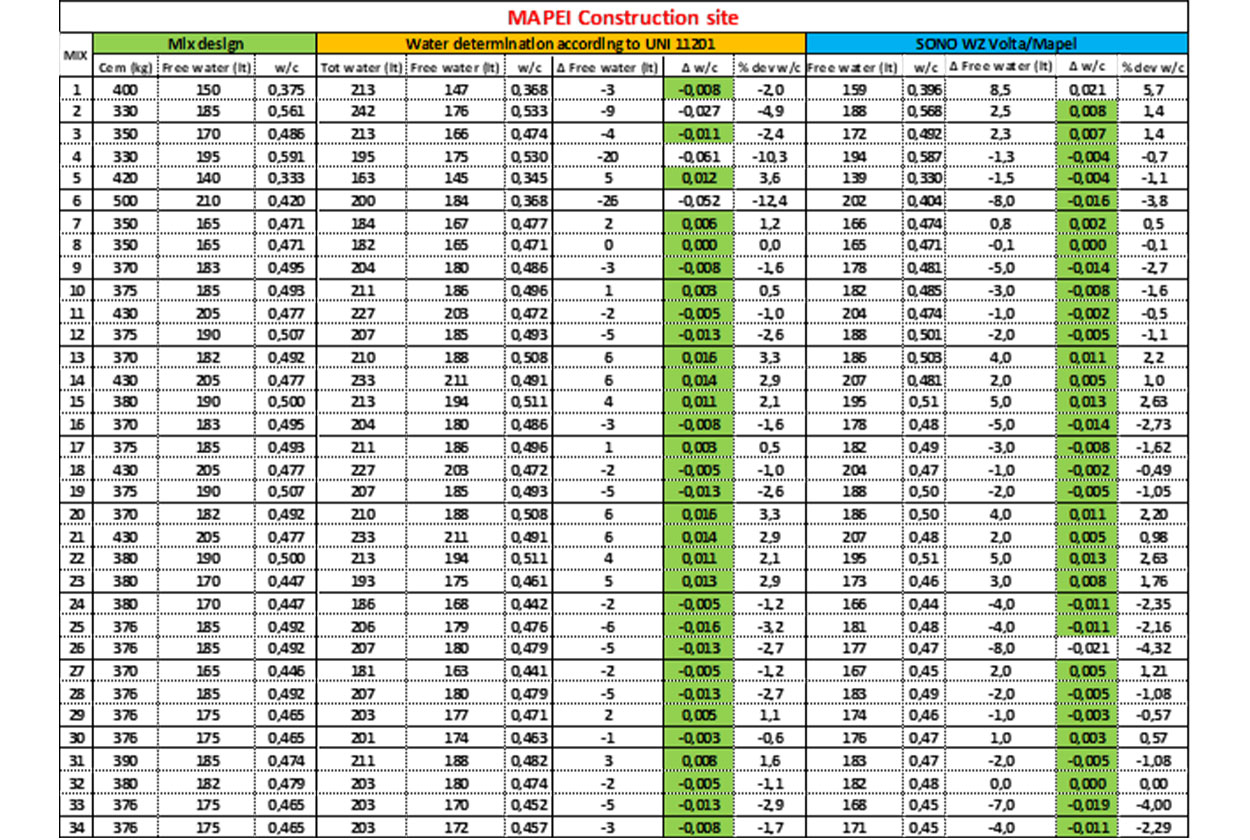

Following the same procedure as before, the table shows the w/c ratio obtained after the determination of the water content applying UNI 11201 and the measurement through SONO WZ.

The same statistical analysis has been applied to evaluate the difference between the two methods.

The first Gauss curve describes the difference between the observed and the target water content. Standard deviation in sensitively lower for SONO WZ (3.8) than UNI method (6.8), which also include possible human errors in following UNI 11201, such as losing of material during the burning or longer burning time than that allowed by the procedure.

Difference in w/c ratio is also evident, showing lower standard deviation for SONO WZ determination.

The analysis of the percentage deviation of w/c with respect to the target w/c confirms that the data obtained with SONO WZ have lower standard deviation.

Conclusions

The extensive campaign of data collection and their thorough evaluation with statistical analysis shows that Sono WZ is a viable alternative to the existing methods for the determination of w/c in fresh concrete. Statistical analysis has shown that SONO WZ is a reliable instrument when compared with the conventional methods, which can provide good results as well, but are affected by different variables.

The instrument SONO WZ is safe, can provide results in short time, and is more suitable for statistical analyses due to the fact that It is not affected by human factor. Moreover, its ease and immediacy of the result allows to collect a large number of data that, canprovide technologists, Works Management, High Surveillance, Official laboratories, a complete and reliable picture of the quality of the concrete.

Essential references

UNI EN 206:2021: Concrete - Specification, performance, production and conformity

UNI 11201:2017 Prove sul Calcestruzzo fresco- Determinazione del contenuto d’acqua

ONORM 3303 (Determination of water content by means of microwave oven)

STATISTICA software, TBCO Santa Clara, USA, www.tibco.com

VOLTA SpA, www.volta.it

Acknowledgement

Giovanni Molentino and Maurizio Pecere, Tecnoprove S.R.L. Ostuni

Fabio Erba Director of Beton Technology S.r.l.

Marcello Pinto, Concrete Flooring Solutions Mapei

Peter Fischnaller, Volta SpA

Authors

Luca Torelli, MAPEI SPA Milan, Italy

Surico Francesco, MAPEI SPA Milan, Italy

Laura Parisio, MAPEI SPA Milan, Italy

Roberto Marino, RM Concrete Consulting, Ravenna, Italy