Our role as tunnelling and excavation facilitators

The strategy of the Group for this sector is to combine effective application with environmental compatibility.

The strategy of the Group for this sector is to combine effective application with environmental compatibility.

When was the Mapei UTT line created and how has it grown over the years?

The UTT Business Unit was created in September 1999, the year I joined Mapei. Initially it consisted of products already in the company portfolio with a cross-section of areas of use and applications, and then it was gradually extended with the introduction of specific products to support excavation and completion of each work. The first project we worked on was the renovation of the Mont Blanc tunnel following the fire in March 1999. This was a very important project, one in which we were given the opportunity to demonstrate the versatility and reliability of our products, many of which were developed in a very short space of time. The line today is more complete and is gradually being extended with new products, driven by our intuition and the demand from both the mechanised tunnelling and traditional excavation markets.

What important projects is Mapei currently working on?

In Italy we are involved in many projects, thanks also to the national investment plan for the coming years in both renovation work and new construction projects. We are working on High-Speed rail projects – such as the third Milan-Genoa link and the Naples-Bari and Catania-Messina stretches – the Brenner base tunnel and the 106 Ionica highway. Overseas, we have done a lot of work in Norway and Northern Europe as a whole. We have also seen considerable growth in Canada and the United States, we are constantly working on projects in South America and we are also starting to see more growth in Australia. As far as Asia is concerned, we work a lot in Singapore and Hong Kong in particular and we are also seeing strong growth in India. The projects we work on are quite diverse, from underground railways to mines, from rail tunnels – a sector undergoing particularly strong growth for environmental sustainability reasons – to road tunnels, hydraulic tunnels and sewer systems.

How much attention is paid to the environmental compatibility of Mapei UTT products? Can you give us some examples?

Environmental compatibility is a fundamental characteristic of our products. We realised right from the start that this aspect would be particularly important for the market and we made very quick progress, including with respect to our competitors, and were the first to establish a reference standard, especially in the field of soil conditioning for TBM excavation works, a sector in which the need for eco-sustainable products is particularly important. We managed to combine high performance products and respect for the environment, something that is not always easy to achieve, and this has led to us building trust with our clients. For example, we have the POLYFOAMER ECO family of foaming agents, which over the last few years has developed from POLYFOAMER ECO 100 to POLYFOAMER ECO 100 PLUS and then POLYFOAMER ECO 1000 PLUS, with a progressive improvement in environmental performance characteristics. We can also say the same for all the products from the line that now come with WGK (Wassergefährdungsklasse) certification, which evaluates the impact a product has on groundwater and classifies the risk of contamination on a scale of 1 to 4, with all our products having a rating of between 1 and 2.

The durability of structures has become a very important topic: what is the approach to this concept across this product line?

As far as durability is concerned, it is very important that products are used and applied correctly. In Mapei, we have the possibility of offering high level solutions that are able to minimise their impact in the event of poor use – often because of the difficult environments where the actual work is being carried out – and guarantee, nonetheless, proper durability. Nowadays, large-scale projects are required to have a service life of at least 100 years, apart from a few exceptions, such as the Brenner tunnel, where a service life of 150 years is required. This long arc of time is due to the high cost of building and repair projects, and also the desire to minimise their social impact, because interrupting a service provokes considerable disruption for its users.

Innovation and research are cornerstones of Mapei: what are your most recent and cutting-edge products from a technological perspective?

Undoubtedly the products from the POLYFOAMER ECO family of foaming agents, and also the admixtures for concrete, which focus on maintaining the concrete's high performances while looking to reduce cement consumption. With our products we try to reduce their impact on the environment to a minimum, and by “low impact” we mean not only low emission of CO2 during the production phase, but also less impact at the moment they are actually applied. And it is here that chemistry is an enormous help in making products more sustainable. In this sense, it is worth remembering that chemistry is not synonymous with pollution, but rather with research, development and the possibility of making people’s lives easier in a sustainable way.

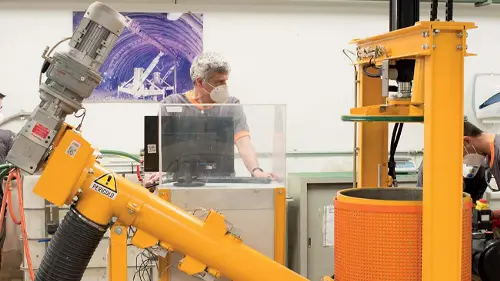

What type of site support can the UTT group provide?

Our support service, which we call Technical Service, starts at the preliminary laboratory phase where we carry out a series of tests based on real site conditions to identify our best proposal to meet the requirements of a particular project. We propose our most suitable products along with their relative dosage rates and application parameters. Once we have been awarded a contract, we go over the tests and parameters again to define certain fine details where required. We then pass to the application phase: we are also present during this phase to make sure a product is used correctly and in the best way possible. We follow sites during each and every phase. The technical service is an important element with highly skilled personnel at the service of clients, who also have ability to develop, if and when necessary, bespoke proposals for a specific site.