Notre Dame: an extraordinary work of restoration

Mapei's solutions for structural strengthening are 'at work' to bring the cathedral back to safety

On April 15, 2019, a serious fire struck the Notre-Dame Cathedral. Since then, the most important phases of restoration have been completed, and every day work is being done to restore the monument to its former splendor.

A decisive first phase completed

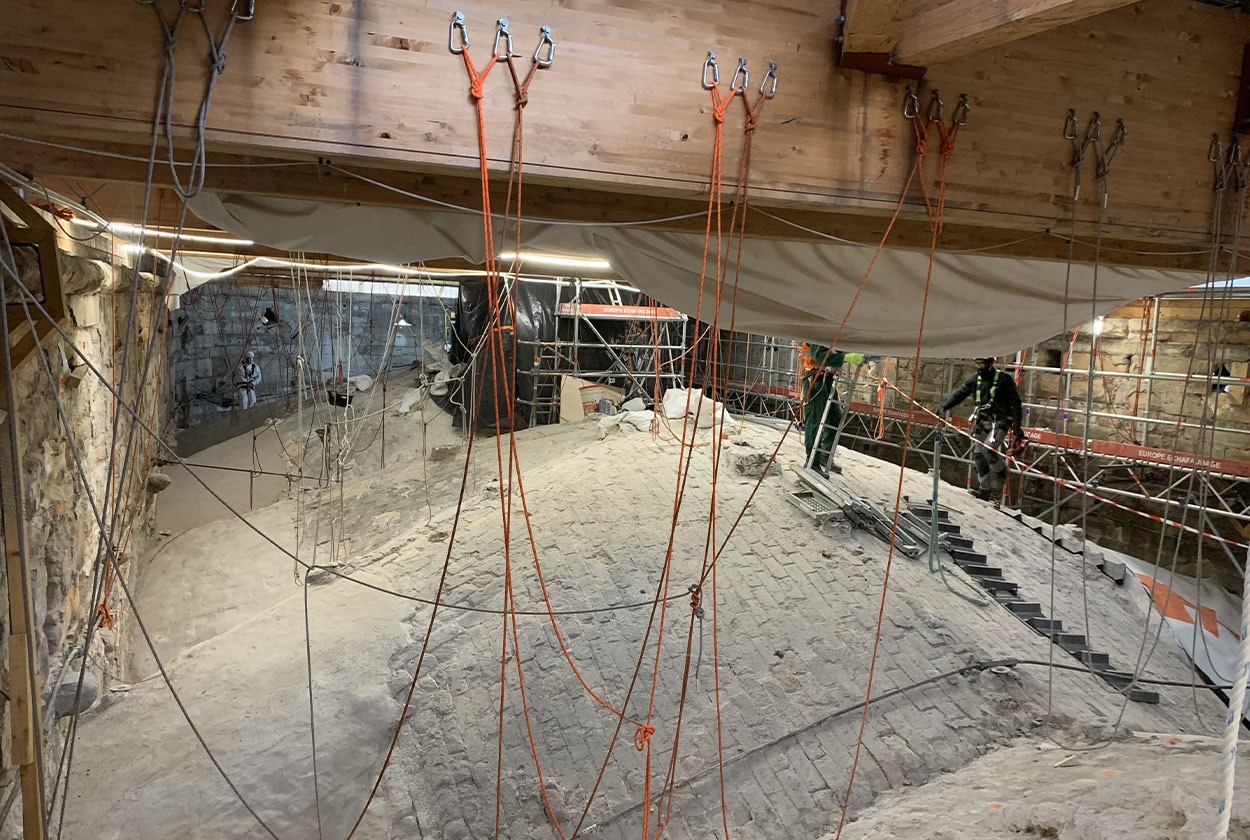

All the roofs destroyed or weakened by the fire have been rebuilt and consolidated. Only the vaulted ceilings in the transept remain to be rebuilt which will happen in the next few months after removing the scaffolding used for rebuilding the dome whose cross has already been installed back on its place.

Mapei is particularly proud to be part of this extraordinary project, collaborating with companies of the calibre of Lefèvre and CCR (BALAS Group) which were awarded the tender commissioned by the Rebâtir Notre-Dame de Paris Public Authority for the restoration of the vaulted ceilings of the transept,the two wings of the transept and the central nave (Lefèvre) and of the choir (CCR).

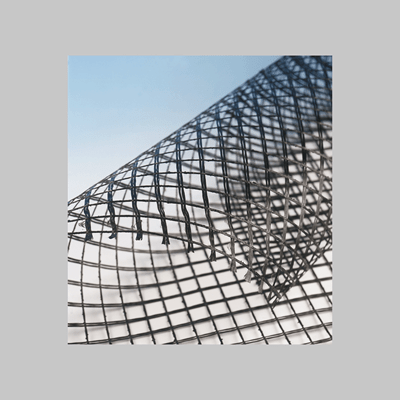

The product employed for this fundamental phase of the restoration of Notre-Dame was a pre-blended, natural hydraulic lime (NHL) and Eco-Pozzolan mortar, which was reinforced with a glass fibre mesh, a solution specifically developed for consolidating historic structures and approved by the team of three architects specialised in historic monuments who are leading the project: Philippe Villeneuve, Rémi Fromont and Pascal Prunet, with advice on structural strengthening provided by the Italian architect Carlo Blasi.

The solution proposed by Mapei underwent a whole year of testing, with numerous experiments conducted in the lab and on site, before being finally approved by the three architects.

Reconstruction work on the vaulted ceilings started in the spring of 2022 after the teams of builders and stonemasons had been trained by Mapei on how to use the solution correctly.

We interviewed Briac Thomas, the engineer in charge of the works for Lefèvre.

What is the scope of your work and what are the technical specifications of the products you use?

Lefèvre worked on all the upper sections of the nave and the two wings of the transept, treated with a hydraulic lime and Eco-Pozzolan mortar. This structural work, which acts as a kind of shell, gives back the masonry vaulted ceilings their original resistance and shape, alleviating the effects of any future movements and preventing fractures in the joints with the adjacent structures.

An hydraulic lime and sand based mortar was injected in the most severely damaged joints between the stones to ensure perfect sealing, with a with particular attention paid to the most exposed areas.

What are the challenges for companies working on a project of this scale, part of our millennia-old historical and cultural heritage?

It is an incredible honour and a privilege to work on the rebirth of Notre-Dame Cathedral, a part of our cultural heritage renowned all around the world that draws in pilgrims and tourists from every corner of the globe. It is an extraordinary project, one where we are able to put all our most advanced knowledge and expertise into practice, and there is no doubt that it can be regarded as just the start of a new horizon in terms of growth.

Reconstructing a building identical to the original is a real challenge, as well as an enormous responsibility! This project is truly out of the ordinary, in which every detail has been meticulously studied in order to guarantee that everything proceeds at the right pace and that the right decisions are made at the right time. Having to reconstruct a building exactly as it was, rather than restore it, is pretty intimidating, it is an incredible commitment, as well as being a real mission!

A site of this scale is a human endeavour that encompasses a wide range of skills and expertise. What is the relationship like between all the various teams on site?

Lefèvre Company