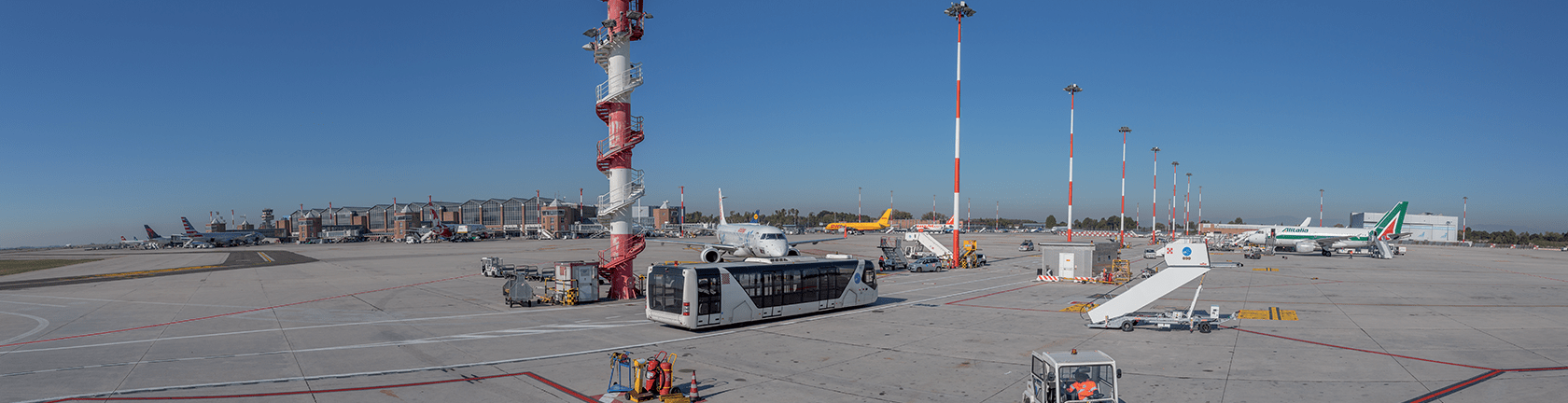

Marco Polo Airport, Venice (Italy)

The runways at Marco Polo airport in Venice were extended and upgraded. Using Mapei admixtures for the bituminous conglomerate meant that a higher amount of RAP (Reclaimed Asphalt Pavement) could be used and a better bond was created between the binder, made from virgin and recycled bitumen, and the aggregates.

Upgrading and regulatory compliance work on the airport infrastructures to handle the expected increase in air traffic.

Between 2018 and 2020, Marco Polo International Airport in Venice underwent a series of major works to increase its operating capacity.

Work was carried out on both the main and secondary runways and new surfacing was installed on the aprons and taxiways.

Work included the following in particular:

- upgrade of the aircraft infrastructures (runways and taxiways) and new surfacing;

- new exit/entrance areas to enable aircraft to move away from the main runway more quickly to increase overall operating capacity;

- upgrade of the safety zones at the ends of the runways;

- upgrade of the drainage systems to discharge rainwater more efficiently.

The secondary runway was extended from 2,780 m to 3,300 m (the same length as the main runway) to improve safety levels and generate more efficient taxiing operations, thereby increasing the overall capacity of the system.

The upgrading work included reconstruction of the entire superstructure.

Other works included upgrading the plant systems and increasing the safety features for both runways, particularly the Aeronautical Ground Lighting and runway incursion prevention monitoring systems, to increase safety standards and manage the expected increase in traffic more efficiently, especially in conditions of poor visibility.

FROM MAPEI: SPECIFIC PRODUCTS FOR BITUMINOUS CONGLOMERATE

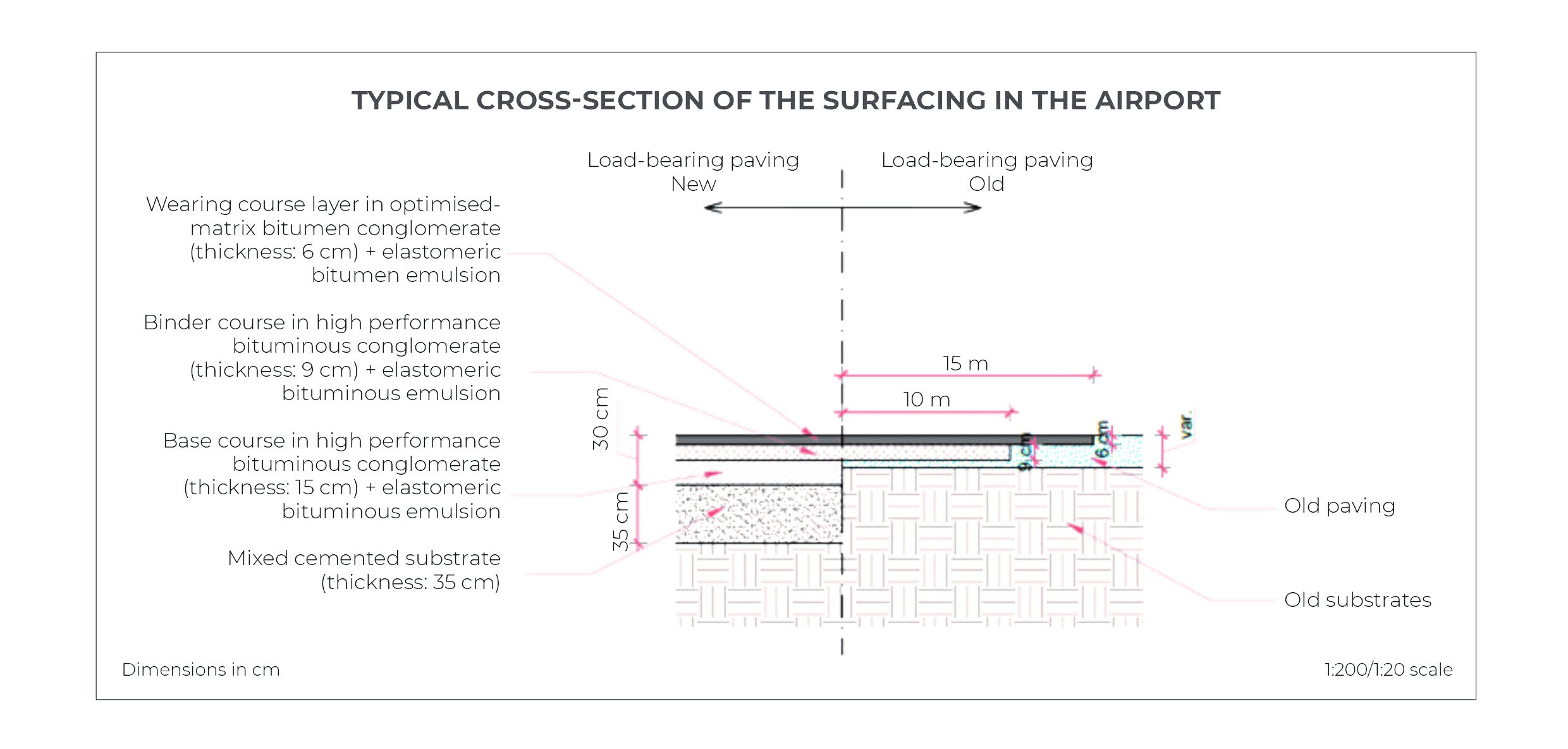

To upgrade the surfacing of the runways, a deep channel was milled out and then rebuilt along the central strip of the runways, while in the remaining areas of the runways, the wear layer only was removed and a new one was installed.

For this project, Mapei supplied products specifically designed for the bituminous binder and base course layers for around 400,000 m2 of new surfacing for the aprons, taxiing areas, entrance/exit areas of the runways and the runways, as well as technical support during the mix design phase and application phase of the mixes.

Going into detail, the following products were supplied:

• MAPEI ACF-L2 regenerating liquid admixture for bitumen for the base course and binder layers;

• MAPEPLAST PAVI 02 polymer used in the production of modified bituminous conglomerate for the base course and binder layers.

The benefits of using these admixtures may be summarised as follows:

- Adding MAPEI ACF-L2 allowed high amounts of RAP (Reclaimed Asphalt Pavement) to be used in the base course and binder layers. MAPEI ACF-L2 significantly improves the rheological properties of the bitumen in the RAP by reintegrating its maltene component (an oily resin present in the original bitumen) consumed by oxidisation and ageing processes. MAPEI ACF-L2 also improved adhesion of both the virgin and regenerated bituminous agglomerate, thanks to its special formulation containing synthetic adhesion promoters.

- The use of MAPEPLAST PAVI 02, which was used in addition to MAPEI ACF-L2 in the base course and binder layers, helped to improve the adhesion of the virgin and recycled bituminous components to the aggregates.

Adding MAPEPLAST PAVI 02 to the bituminous conglomerate also increased the shear modulus of the conglomerate and the benefit of this admixture is that it significantly improves the resistance of the surfacing to fatigue and permanent deformation (or rutting, which forms along the trajectory of the wheels of aircraft).

.jpg?sfvrsn=4b4f4f70_4)

.jpg?sfvrsn=404f4f70_4)

.jpg?sfvrsn=414f4f70_4)