Mapestone System for the new Saint Francis Road at Santa Maria degli Angeli

The Mapestone System helped rebuild the road alongside the Basilica, "heir" of the church where the saint founded his order.

The Mapestone System helped rebuild the road alongside the Basilica, "heir" of the church where the saint founded his order.

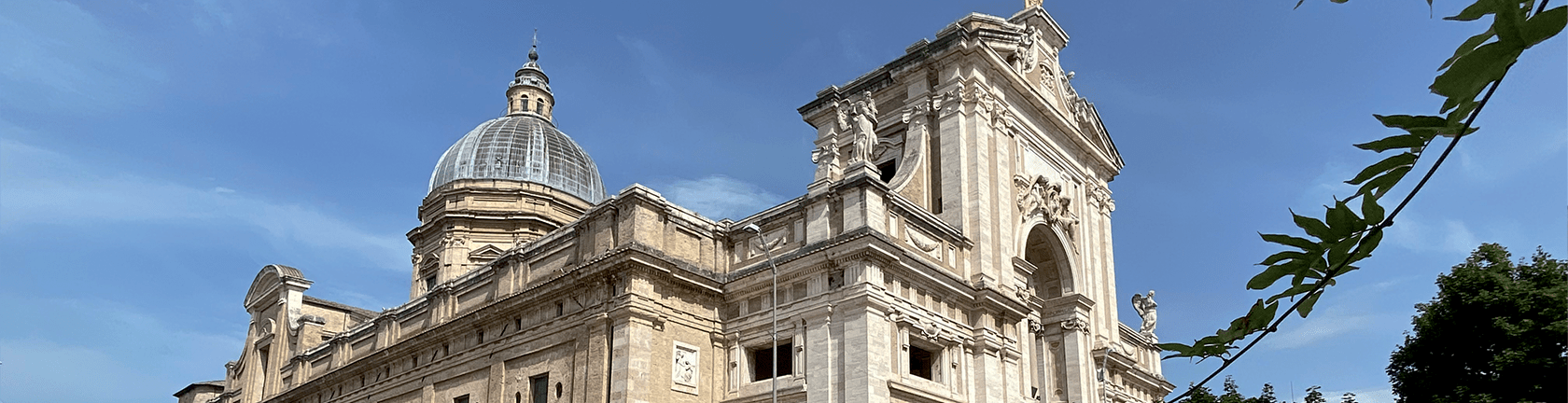

The “new” St. Francis road is the central part of the straight around 600 m long running in Assisi (Central Italy) along one side of the Basilica of S. Maria Degli Angeli, the large church wanted by Pope Pius V and built between 1569 and 1679 in Assisi, and today still welcoming worshippers visiting the Basilica for the Pilgrimage of Forgiveness (31st July to 2nd August), the ritual so strongly desired by St. Francis.

The complex incorporates the various structures of the Franciscan convent built around the Porziuncola church, which dates back to the 10th-11th century. Dedicated to S. Maria Degli Angeli, St. Francis relocated to this church in 1205, which he then restored and where he founded the Franciscan Order.

Inside the church there is also the Chapel of Transit, a small room of the infirmary where St. Francis died on 3rd October, 1226.

So it is hardly surprising that the road is dedicated to the patron saint of Italy and is a highly significant transit and connection route, which was also indicated on the most ancient prints and maps of the area.

DURABLE AND RESISTANT FLOORS

The paving, installed between 2004 and 2006 using 10/12 porphyry blocks laid in straight lines, had been in a precarious condition for some time, due to deformations and hollows in the paving units, widespread subsidence, rutting, detached blocks, evidence of localised repair work to the paving with grouting between the blocks using cementitious mortar and even areas patched up by replacing the porphyry paving with bitumen.

The pathway, therefore, was a daily risk to the safety of pedestrians and passing vehicles.

This is why the local council decided to commission a project to carry out targeted maintenance work on the road, and at the same time applied for funds from the relative government ministries to cover the costs.

Their aim was to make the new stretch of road much safer and more durable and to drastically reduce maintenance costs.

The project was split into two phases, starting with the removal and recovery of the old porphyry paving blocks, demolition of the concrete foundation slab and the repair and replacement of the various damaged or deteriorated utilities under the road.

The second phase regarded the installation of the various layers for the new paving, which was carried out after compacting the substrate, verifying its load-bearing capacity by load plate testing, and installing a new, properly dimensioned foundation slab by using DYNAMON XTEND W401 R, acrylic super-plasticizer for concrete. The actual paving blocks weren’t installed in straight lines as before, but in an overlapping arc pattern in order to re-use more of the old blocks, and the project specified using the MAPESTONE SYSTEM consisting of MAPESTONE TFB 60 for the installation bed and MAPESTONE PFS2 FLEX to grout joints.

Specifically formulated for making cost-effective, durable, urban stone paving with lower maintenance costs, including paving exposed to high levels of traffic, the MAPESTONE SYSTEM includes a range of products in exposure class XF4 that comply with prescriptions and the requirements of both Italian standard UNI 11714-1:2018 and European standard EN 206-1 to guarantee the durability of the paving.

Thanks to its resistance to freeze-thaw cycles, de-icing salts and rain, paving made using the MAPESTONE SYSTEM is a monolithic system that doesn’t fail and remains unchanged over time, thereby eliminating the need for maintenance work for a number of years.

The paving blocks, measuring around 5 cm thick on average, were installed using MAPESTONE TFB 60 pre-blended mortar, which was supplied in bulk quantities in silos for more efficient and cost-effective logistics and for the benefits this supply solution brings in terms of sustainability. To grout joints (10 mm wide on average), on the other hand, the product used was MAPESTONE PFS 2 FLEX, the new, pre-blended mortar from the MAPESTONE PFS range.

Thanks to its low modulus of elasticity and a pull-off value three times higher than traditional grout, MAPESTONE PFS2 FLEX has the capacity to absorb stresses and strains from passing vehicles more effectively. These properties help increase the resistance of joints when in service, which plays a key a key role in guaranteeing the durability of paving.

Again in compliance with UNI 11714-1:2018, because the paving blocks were installed on a compact bed, the project also specified the inclusion of perimeter joints where the paving comes into contact with the lateral pavements and expansion joints at regular intervals following the arc pattern. The expansion joints were sealed with MAPEFLEX E-PU 21 SL, a two-component, castable, epoxy-polyurethane sealant with high resistance to chemicals, high mechanical properties and high modulus of elasticity.

Designed in November 2020 and commissioned in January 2021, work on the site started in February and was completed at the end of July, perfectly on schedule and ready to welcome the flocks of pilgrims who, after months of absence, were once again able to start visiting the places of worship of St. Francis.