Mapei technology transforms waste into a resource material

The Re-con line solutions help manage and recycle concrete and washing slurry

The Re-con line solutions help manage and recycle concrete and washing slurry

The rising cost of fuel and virgin raw materials has caused an increase in the total cost of ready mix concrete production in recent years. These costs have even accelerated during and after the Covid-19 pandemic due to disturbances in global logistics and raw material supply chains. In combination with the increasing awareness in society about the need for more circular production models, the management of waste streams in concrete production has come into the spotlight as a major cost and environmental issue. Returned concrete and slurry from washing of trucks, which previously could be disposed at low cost, is now becoming more and more expensive to handle.

Mapei has worked on this issue for many years and can offer products and solutions that transform returned concrete and washing slurry into resource materials. The Mapei RE-CON line helps concrete producers to reduce the use of water and raw materials like sand, aggregates and cement, while also reducing water pollution.

The Re-Con line circular process

The RE-CON line of products helps concrete producers become sustainable by offering solutions that transform, reduce and recycle waste streams. A 50.000 m3 yearly production normally has a rate of returned concrete of 5%, i.e., 2500 m3 or approximately 5800 tons. It also has a waste stream of washing slurry. If there is no possibility to re-use the returned concrete, it will have to go to landfill as waste. The slurry must in any case be deposited in landfill or in an approved deposit as it contains heavy metal contamination like hexavalent chrome. The cost of this handling can be tens of thousands of Euros for the production in this example.

If the RE-CON line solutions are applied in concrete production, substantial savings can be achieved. Not only are handling costs eliminated with the Re-Con Line solutions. The transformation of the waste materials into recyclable aggregates also leads to

savings by reducing the need for virgin raw materials.

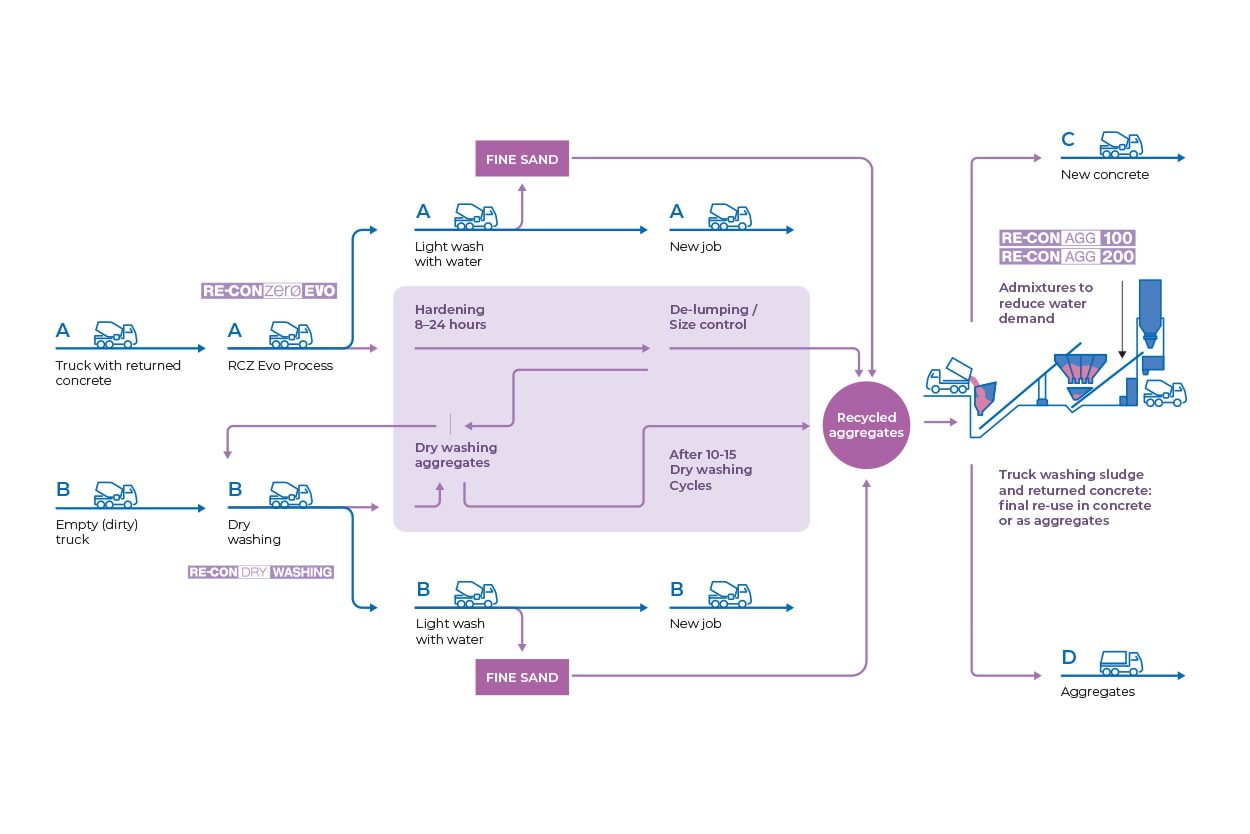

The process is best described in this flow diagram. There are two alternatives for the trucks that return back from a delivery at a building site to the batching plant. Either it contains some returned concrete (A), or it is empty of concrete but has about 200 kg of cementitious residue that covers the inside of the mixer drum in a thin layer (B). In Case A, the returned concrete is treated with the RE-CON ZERO EVO process which transforms the fresh returned concrete into a granular material that is emptied on the ground and left to dry and harden for 8-24 hours. After this, the truck can take a light wash and is then available for the next job. For the concrete truck driver, the process has taken about 15 minutes and instead of a flow of concrete that needs to be handled and processed, the batching plant now has an available volume of aggregates. This material is called Re-Con Zero aggregates and it can either be sold as a base course or backfill material, re-used in the production of new concrete or as a Dry Washing aggregate in Flow Case B. When a truck returns as empty but dirty (B) it goes directly to do the RE-CON DRY WASHING process. Approximately 1 m3 of aggregates, or 2500 kg is fed into the empty truck and is rotated back and forth inside the drum for about 4 minutes. During this rotation, the aggregates clean the inside of the drum and absorbs around 70% of the cementitious residue onto the surface aggregates, forming a new layer that will dry and harden in 12-24 hours. The truck empties the aggregates in a material storage unit and can then have a light wash where the remaining residue in the form of fine sand with a minor element of cement is collected for sedimentation and dewatering.

The need to dry wash an empty truck varies from case to case. Normally it is only needed after the last load of the day. But in a hot climate or in special cases, concrete trucks have to be cleaned also during the day between deliveries. The dry washing aggregates can be re-used for about 10-15 times before its slurry absorbing abilities are no longer efficient enough. It is then used in process step (C) as replacement for virgin raw materials in new concrete or in (D) where it is sold externally as aggregates. In step (C) the use of Re-Con AGG admixtures can save a lot of water and thereby cement, by keeping the concrete made with recycled aggregates flowable for a longer time after mixing.

Transforming returned concrete into

aggregates

Since concrete generally needs to be used within 1-4 hours from the mixing, over-ordering and quality issues can result in a daily flow of tens of cubic metres of concrete back to a single mixing plant, a waste stream that requires significant resources, time and costs to handle and in many cases transport it to landfill. Mapei revolutionized the handling of returned concrete with the introduction of RE-CON ZERO in 2010. Returned concrete can now be transformed into a recyclable aggregate material. The transformation happens thanks to a patented 2-part system including a superabsorbent polymer and a hardener. The water in the concrete is bound by the superabsorbent and the hardener accelerates and stabilizes the process. The returned concrete can be transformed in the truck mixer or in a separate process if the truck is needed quickly for a new job. The result is a recycled aggregate can be used in new concrete or sold as backfill material, leading to substantial savings in handling costs. The aggregates can also be used in an intermediate process of absorbing truck washing slurry in the RE-CON DRY WASHING process.

Cleaner water and reduced waste from concrete trucks with RE-CON DRY WASHING

The RE-CON DRY WASHING method was invented by Mapei in 2019. It greatly reduces washing slurry waste and washing water consumption from concrete trucks by using the absorbing properties of the RE-CON ZERO EVO aggregates made from transformed returned concrete. The method makes it possible recycle washing slurry into a recycled aggregate, instead of having to process, transport and deposit it at landfills. Much less water is needed to complete the cleaning of the truck mixing drum after it has been dry washed. The residual washing water has a lower solids content, lower pH and a lower risk of containing heavy metals like hexavalent chrome. All this is due to the unique absorption of cementitious residue onto the dry washing aggregates. And there is one more advantage: Mapei analysed and tested the Dry Washing aggregates together with the renowned research institute SINTEF in Norway and discovered that the Re-Con Dry washing particles absorb carbon dioxide through the process of carbonation. The RE-CON Line offers unique possibilities to produce carbon negative aggregate materials and Mapei Research continues in this field.

Reducing water and cement when using demanding materials in concrete with RE-CON AGG admixtures

There is a growing need to shift to use more recycled materials and to utilise manufactured sand and lower quality sands in higher ratios in concrete production. Recycled aggregates generally have a higher water absorption due to their porous surface structure. Manufactured sands with high fines content and low-quality sands containing clay minerals can cause a higher water consumption in concrete mixing. With a high water demand, a higher usage of cement automatically follows, since the water/cement ratio is dictated through industry standards. With the help of the RE-CON AGG admixtures, increased ratios of water demanding sand and aggregates can be used without increasing the need for cement. The RE-CON AGG polymers block the porous surfaces and crystalline structures in demanding aggregates and sand from absorbing the mixing water from the concrete in its fresh state. Instead of getting soaked up into the porosities or laminar mineral layers of the sand or aggregates, the mixing water stays available in the fresh concrete, keeping it flowable for much longer than it would have been without these admixtures. The alternative would have been to add more water and more cement to the mix, leading to higher costs and a bigger carbon footprint.