Mapefast Ultra: innovative technology for sustainable concrete

Mapefast Ultra is the new admixture by Mapei that enabled the Genoa-San Giorgio Bridge to be constructed in record time

Mapefast Ultra is the new admixture by Mapei that enabled the Genoa-San Giorgio Bridge to be constructed in record time.

THE CONCRETE USED FOR GENOA: SUSTAINABLE, DURABLE AND RESISTANT TO AGGRESSIVE AGENTS

Sustainability was the guiding principle that characterised the construction of the new Genoa-San Giorgio Bridge. In particular, the concrete used for the bridge was a CEM III/A cement, a binder where 40 % of the clinker is replaced by blast-furnace slag, a by-product of the steel making process. This type of cement is characterised by low CO2 emissions (around 500 kg of CO2/Tonne, as opposed to around 900 kg of CO2/Tonne with traditional Portland cement) and the recognized ability for producing strong and durable concrete, resistant to the aggressive atmo-spheric agents, such as the concrete designed for the construction of the bridge (exposure class XA1 according to EN 206).

A NEW BRIDGE IN JUST 13 MONTHS: MAPEI’S CONTRIBUTION

The second characterising feature of the project was that the new bridge, a key infrastructure for boosting the economic recovery of Genoa, had to be completed in as short a time as possible. In fact, from 25th June 2019, the date the first concrete was placed for the erection of pile 9, to 3rd August 2020 when the bridge was inaugurated, it took just 13 months, a record if we consider the complexity and the size of the structure.

The most imposing elements of the bridge are the 18 piles, concrete giants 40 m tall, which support the bridge deck. Their external dimensions (9.50 by 4 m) are constant along their entire vertical profile in order to guarantee the cohesive perspective of the structure and to make their construction quicker, thanks also to the use of the same type of external, modular climbing formwork. The piles have an elliptical form which allows light to flow over their surface to help mitigate their visual impact on the urban landscape.

MAPEI WITH THE UNIVERSITY OF PADUA TO FORMULATE A BESPOKE SOLUTION

However, despite these precautions it would never have been possible to complete the bridge within the scheduled time without the use of MAPEFAST ULTRA, an innovative accelerating admixture developed in the Mapei Research & Development laboratories in collaboration with the CIRCe Research Centre of the Department of Geosciences at the University of Padua (Italy).

This is because CEM III/A is a slow hardening binder and would have been unable to develop the required mechanical strength to proceed quickly with the erection of the piles, particularly in wintertime when the low temperature slows down the hydration of the cement. In fact, the Pozzolanic reaction of the slag, which accounts for 40% of this particular type of binder, is not triggered immediately, but gives significant contribution to mechanical strength only after several weeks from the placement of the concrete.

Thanks to the use of MAPEFAST ULTRA however, it was possible to remove the formwork, even in the middle of winter, just 16 hours after placing the concrete and to proceed with construction of the piles at the extraordinary rate of 3 piles per month.

MAPEFAST ULTRA was added along with the other components during the normal cycle of the concrete production. To ensure the concrete retained the S5 consistency class (slump > 210 mm) while being transported from the mixing plant to the jobsite, a combination of Dynamon Xtend W400N and Dynamon EW superplasticizers was also used. Table 1 shows the composition of the concrete used to construct the bridge piles.

| Type of cement | CEM III/A 42.5N |

| Dosage of cement | 400 kg/m3 |

| Filler | 70 kg/m3 |

| Dynamon Xtend W400N | 0,75% on weight of cement |

| Dynamon EW | 0,5% on weight of cement |

| Mapefast Ultra | 2,66% on weight of cement |

| Consistency class | S5 (slump > 210 mm) |

| Maximum diameter of aggregate | 16 mm |

TABLE 1. Composition of the concrete used to construct the piles for the new Genoa-San Giorgio Bridge

IMPROVED MECHANICAL PROPERTIES THANKS TO A MAPEI ACCELERANT

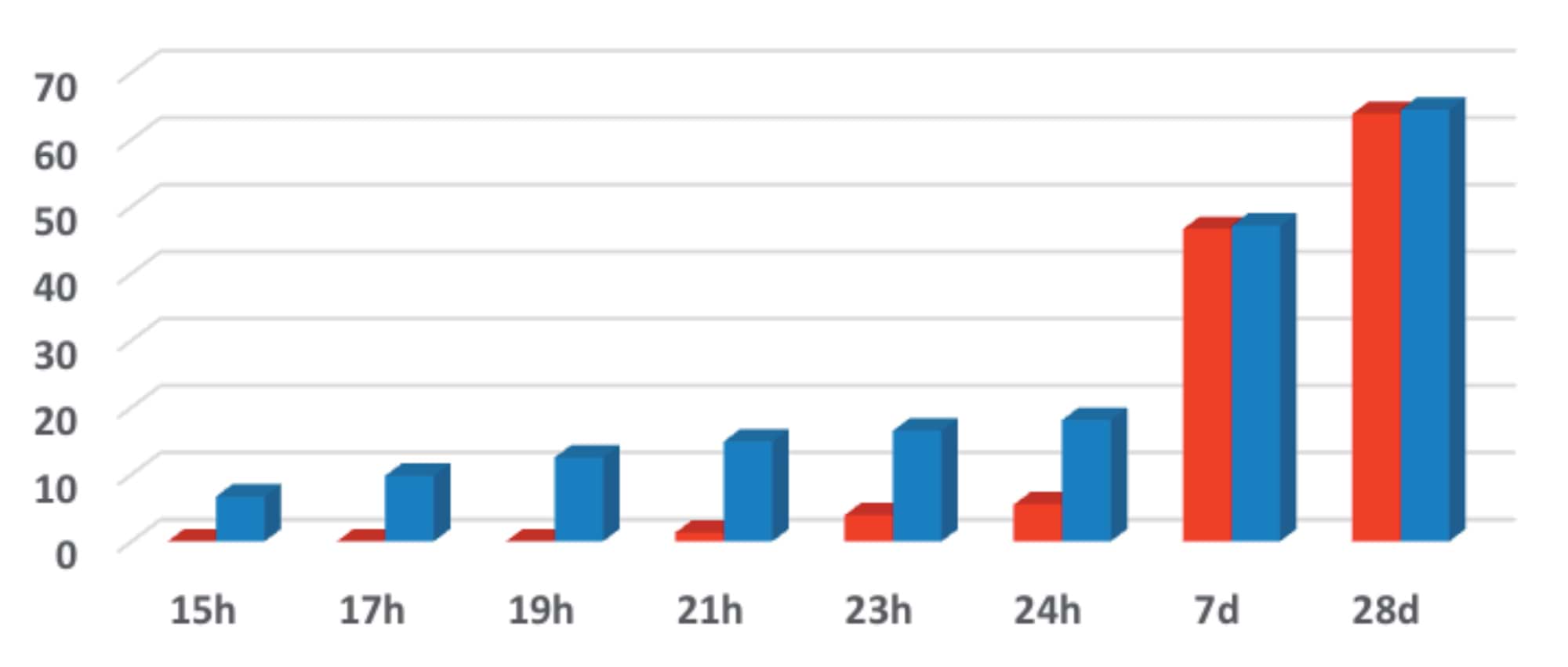

The development of compressive strength of concrete specimens made with the “mix-design” of the bridge piles (blue bar) is shown in Figure 1, in comparison with the same mix without MAPEFAST ULTRA used as a control (red bars). This figure clearly shows the outstanding contribution of MAPEFAST ULTRA in developing early compressive strength. The laboratory samples were cured by simulating a thermal cycle typical of the Ligurian coast, whereby the initial temperature inside the concrete placed for the pile was 15 °C and the final temperature, after curing, was 34 °C. The graph indicates that, after 19 hours of curing, the compressive strength of the samples containing MAPEFAST ULTRA was higher than 12 MPa, whereas the value for the reference concrete was still null and, even after 24 hours, the compressive strength without MAPEFAST ULTRA would still have been insufficient for the formwork to be removed.

Based on these laboratory results, MAPEFAST ULTRA was used for the erection of all the bridge piles, thereby enabling the bridge to be constructed within the time scheduled.

The graph also shows that, unlike traditional accelerating admixtures, MAPEFAST ULTRA has no negative effect on the long-term compressive strength of concrete. This behaviour is due to its special reaction mechanism, based on the effect of nano-seeded nucleation of the transition metal silicate hydrates, which represent the active component of the admixture. This effect is associated with a different hydration mechanism, which passes from heterogeneous nucleation to homogeneous nucleation, and has a positive effect on the microstructure of the hydrated cement paste, making it less porous and less permeable to water and aggressive agents.

THE 2018 MARIO GIACOMO LEVI MEDAL FOR THE ADMIXTURE MAPEFAST ULTRA

For the research work carried out on the development and industrialization of MAPEFAST ULTRA, in 2018 the Industrial Chemistry Division of the Italian Chemistry Society awarded Mapei and the Circe Research Centre of the University of Padua the Giacomo Levi Gold Medal for the best joint industrial-academic research work to reach the industrial production phase (see Realtà Mapei International no. 72).

The important role played by MAPEFAST ULTRA in the construction of the new Genoa-San Giorgio Bridge confirms the importance of collaboration between industry and the scientific community when developing innovative technology and is testimony of Mapei’s commitment to actively promoting and encouraging the transition towards sustainability in the construction sector and increasing awareness of the principles of a circular economy.

Find out more about Mapei solutions for the concrete industry at: https://www.mapei.com/cis/en/home-page

Giorgio Ferrari. R&D Laboratories, Mapei SpA (Italy)

Gilberto Artioli. CIRCe Research Centre, University of Padua (Italy)

Bibliography

Artioli, G., Valentini, L., Dalconi, M.C., Parisatto, M., Voltolini, M., Russo, V., Ferrari, G., 2014. “Imaging of nano-seeded nucleation in cement pastes by X-ray diffraction tomography”, International Journal of Materials Research, 105 (7).

Artioli, G., Valentini, L., Voltolini, M., Dalconi, M.C., Ferrari, G., Russo, V., 2014. “Direct imaging of nucleation mechanisms by synchrotron diffraction micro-tomography: superplasticizer-induced change of C-S-H nucleation in cement”, Crystal Growth & Design, 15 (1).