Sustainability

/

5/4/2023

Make the difference, one bag after another!

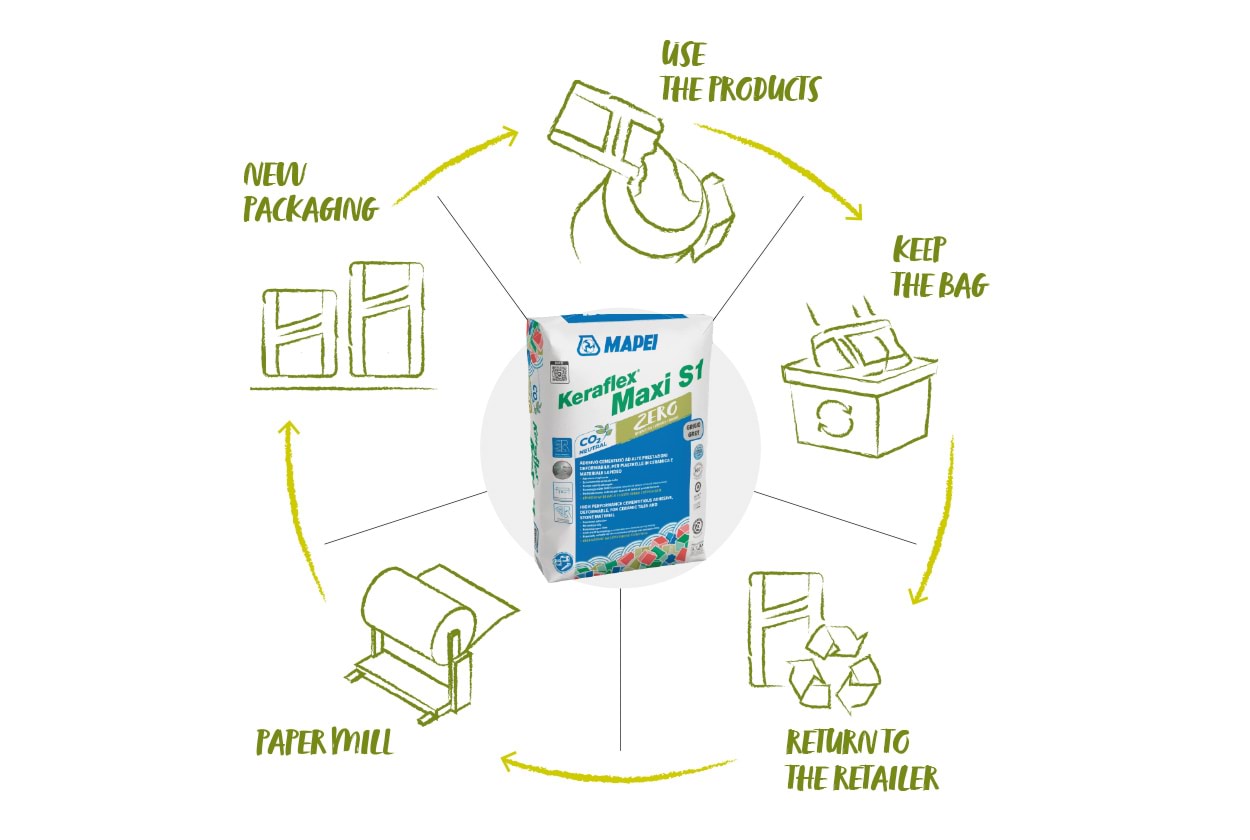

A pilot project has been set under way to salvage paper bags at the end of their life cycle.

A pilot project has been set under way to salvage paper bags at the end of their life cycle.

Mapei is committed to increasing the amount of recycled paper packaging

Sustainability at Mapei is not only reflected in the great work that Research & Development is doing to optimise products with increasingly low environmental impact while maintaining high quality and durability, but also in the packaging of the products themselves.

In recent years, we have been working on replacing virgin plastic with recycled plastic, as in the case of the Mapei wall coatings range, all in drums certified with the “plastic second life” eco-label.

With circularity in mind, we are also carrying out numerous studies into the end-of-life of our products and packaging.

For the past few years, all multilayer packaging (paper/PE middle ply/paper) of powdered products has been analysed in accordance with Italian standard UNI 11743 and actual recyclability has been assessed using the Aticelca (the Italian Association that brings together technicians and experts working in the paper industry) 501 evaluation system. The UNI standard analyses both process parameters (pulping, coarse waste, flakes and adhesive particles below 2.0 mm) and product quality (sheet formation and optical inhomogeneities).

In accordance with this standard, paper packaging is treated as it would be in a paper mill: the ensuing result is then assessed to ensure every aspect of the packaging at the end of its life cycle (i.e., emptied of any dust it might contain) is compatible with current recycling processes and can guarantee a sufficient yield in terms of recovered fibers to make it useful for making new paper.

Paper packaging waste (amongst the most abundant in Europe) is recovered rather than lost with circularity in mind.

A virtuous example of circularity

All of Mapei multilayer packaging was found to be class A and B, i.e. “recyclable paper” according to Aticelca classification, producing yields of up to 90% and 80% respectively, as well as very low content in terms of glue and other substances that might disrupt recycling.

Unfortunately, this kind of packaging is not salvaged yet, which is why the paper industry is deprived of many tonnes of material that could be recycled into new packaging and paper products. Multilayer bags are rarely disposed of properly, very often they are just dumped in with the undifferentiated waste.

So, after being contacted by one of the most virtuous paper mills in Northern Italy, Cartiere SACI, we started to think about a way of retrieving packaging that was classified as recyclable.

This immediately turned out to be an uphill challenge: a third party had to be found that could act as a collection centre for the packaging: so, with the help of several Mapei SpA’s departments, i.e. sales, purchasing, Research & Development and packaging, we managed to come up with a solution.

We decided to join the REC Consortium (Recupero Edilizia Circolare), a project organised by FEDERCOMATED (the Italian National Federation of Building Material Retailers). Francesco Freri, General Manager of 4Bild, is the President of the Federation and Emanuele Della Pasqua, CEO of Vaga (a subsidiary of the Mapei Group), is one of the advisors: this is the first consortium of building material retailers for the collection of building/demolition waste.

The REC consortium brings together building material retailers interested in promoting the recovery of construction&demolition (C&D) waste. Consortium retailers can set up dedicated areas called Preliminary Collection Centres (CPR), where they collect waste based on simplified 'temporary storage' procedures. This ensures this waste (amongst the most abundant in Europe) is recovered rather than lost with circularity in mind.

Moreover, this project also means lots of the retailers' customers do not have to travel as far in their lorries to the benefit of the environment.

As in the case of C&D waste, we have decided to use the same collection method for end-of-life multilayer packaging. This kind of packaging, recovered from distributors belonging to the REC consortium, will then be sorted in collection centres and sent off to the paper mill for recycling.

Thanks to cooperation along the entire chain involving the key players of the sector (REC consortium, Cartiere SACI, Assocarta, Comieco, Assografici and Gipsac, the Group of Italian manufacturers of paper packaging), we are currently launching a pilot project for the recovery of end-of-life packaging: "Make the difference, one bag after another!".

Once the project is launched, we will monitor the quantities of packaging destined for recycling: the hope is to extend this virtuous example of circularity and cooperation along the supply chain right across Italy, and later on, right across other countries

An award for the eco-design of packaging

For the fourth year running, Mapei has been awarded a prize in the Ecopack competition organised by CONAI in the field of eco-design. Since 2014 it has been awarding prizes to Italian companies that have adapted their packaging to make it more sustainable and reduce its impact on the environment.

Mapei entered the competition presenting two best practices:

- Replacing pallet packaging sheets made of 100% virgin LDPE polymer with sheets made of 40% LDPE and 60% PCR (second life plastic).

- Replacing IBCs (intermediate bulk containers) made of 100% virgin HDPE polyethylene for holding liquids with containers made of 30% recycled polyethylene.

Mapei's entry and those from other companies were analysed using the CONAI EcoTool, which allows the effects of eco-design operations implemented by companies on packaging to be calculated based on a simplified analysis of the entire life cycle by means of a before-after comparison in terms of water and energy savings and reduction of CO₂ emissions.