IRCCS Galeazzi-Sant’Ambrogio Hospital

Cementitious adhesives and anti-fracture membranes for this new hospital recently inaugurated in the former Expo area.

Cementitious adhesives and anti-fracture membranes for this new hospital recently inaugurated in the former Expo area.

The new Galeazzi Sant'Ambrogio Hospital

The new Galeazzi Sant’Ambrogio Hospital opened its doors to the public in Milan on Monday 22nd August, bringing together within the complex the Galeazzi Institute of Orthopaedics and the Sant’Ambrogio Institute of Clinical Medicine. The hospital is one of the cornerstones of the future research, innovation and healthcare ecosystem within the MIND, Milano Innovation District, based in the area that hosted the Milan Expo in 2015.

The structure was designed according to the most advanced standards regarding sustainability and functionality and has been registered for assessment to be awarded Leed Gold V4 Certification for its environmental sustainability credentials.

A hub dedicated to healthcare, research and teaching

The new complex now combines under one roof the IRCCS Istituto Ortopedico Galeazzi (Galeazzi Institute of Orthopaedics), the leading hospital in Italy in terms of the number of orthopaedic prostheses implanted and the leading hospital in the Lombardy region in terms of patients undergoing orthopaedic surgery, and the Sant’Ambrogio Institute of Clinical medicine, one of the leading centres in Italy for the treatment of cardiovascular pathologies.

Apart from the orthopaedics and cardiovascular departments, there are also departments specialising in neurosurgery and bariatric surgery. Within the complex there are also large areas dedicated to university courses and scientific research because, in 2006, the Galeazzi Institute of Orthopaedics was awarded IRCCS (Scientific Institute for Research, Hospitalization and Healthcare) status by the Italian Ministry of Health for its research into illnesses and pathologies of the musculoskeletal system.

The hospital of the future

The structure extends over an area of almost 180,000 m2 and was designed according to the most advanced standards regarding sustainability and functionality. Constructed with a modern conception of architecture, the building is 16 storeys high and has a main body where the hospital departments and activities, the research laboratories and the university functions are concentrated. There are also three other buildings that provide crucial services: a technological centre, a hospital gas plant and an ecology island.

The new hospital was built applying the most modern and efficient solutions regarding energy savings and environmental sustainability in order to reduce waste, energy consumption, noise pollution and the emission of pollutants in general as much as possible. The materials chosen are eco-sustainable and healthy, with the ability to absorb smog using atmospheric purification methods, as well as containing self-cleaning properties. And this is why the new Galeazzi Sant’Ambrogio Hospital has been registered for assessment and is a potential candidate to be awarded Leed Gold V4 Certification for its environmental sustainability credentials.

Waterproofing and installing ceramic tiles

In May, 2019 Mapei supplied admixtures (DYNAMON XTEND W500 SN, DYNAMON EW, MAPETARD) for the concrete that was used to create the largest ever foundation slab in Europe: a good 32,836 m3 of self-compacting concrete were poured non-stop for 94 hours (see Realtà Mapei International no. 76).

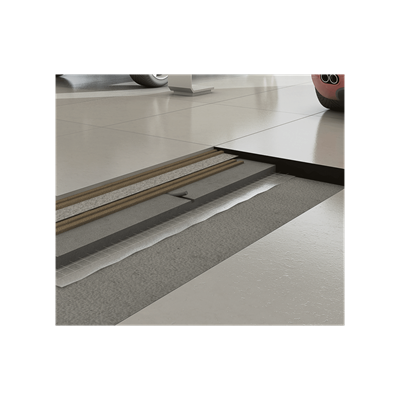

For the latest intervention, installation of tiles in the internal areas, there was a very tight schedule and large-size porcelain tiles needed to be installed on a substrate that had not been fully cured. To prevent having to cut the porcelain tiles to respect the shrinkage joints in the substrate, before installing the tiles in the corridors, MAPEGUARD UM 35 was applied over the surface, a waterproofing, anti-fracture and uncoupling membrane, along with MAPETEX SYSTEM anti-fracture, non-woven fabric membrane. These membranes guarantee sound, high-performance installation on cracked substrates and on substrates not fully cured, thereby preventing any irregularities in the substrates damaging the finished flooring. These membranes were bonded with KERAFLEX EXTRA S1, a cementitious adhesive with variable rheology which was chosen due to its deformability properties, and, in some areas with ADESILEX P9 EXPRESS rapid-setting cementitious adhesive with extended open time.

The porcelain tiles were installed using KERAFLEX EASY S1, an easy to apply, deformable cementitious adhesive with extended open time. The joints were grouted with KERAPOXY CQ two-component, epoxy grout, with a bacteriostatic agent and BioBlock® technology. All the expansion joints were sealed with MAPESIL AC pure, mould-resistant acetic sealant.

Carrara marble slabs were installed on the stairs and landings in the service areas with ADESILEX P9 EXPRESS rapid-setting cementitious adhesive with extended open time.

The substrates in the bathrooms had been previously waterproofed with MAPEGUM WPS ultra-quick drying, flexible liquid membrane and MAPEBAND EASY tape.