Giorgio Amarelli liquorice museum

Aesthetics and functionality for “sensorial” resin floors to withstand intense pedestrian use in the factory store.

There is documentary evidence showing that, as far back as the 16th century, the Amarelli family from Rossano (Southern Italy) was already harvesting and selling liquorice. In 1731 the family founded their first extra-agricultural facility to extract juice from the roots of liquorice plants, a product unique to the Calabria area. The story of the family’s successful business over the last three centuries is on display at the Giorgio Amarelli Museum of Li-quorice which, since 2001, has been complementing the family’s home in a fifteenth-century mansion house.

There is documentary evidence showing that, as far back as the 16th century, the Amarelli family from Rossano (Southern Italy) was already harvesting and selling liquorice. In 1731 the family founded their first extra-agricultural facility to extract juice from the roots of liquorice plants, a product unique to the Calabria area.

The story of the family’s successful business over the last three centuries is on display at the Giorgio Amarelli Museum of Liquorice which, since 2001, has been complementing the family’s home in a fifteenth-century mansion house.

In 2001 the museum won the coveted “Premio Guggenheim Impresa e Cultura” (Guggenheim Award for Business and Culture) and, in 2004, the Italian Postal Service dedicated a stamp to the museum for its “Italian Heritage and Culture” series of special edition postage stamps.

In 2017 a new factory store was built to welcome visitors before taking their tour of the Amarelli museum and production facility.

Mapei supplied their own brand products for the liquorice-coloured resin floors and cementitious systems for wall coverings, turning the idea of the man behind the design of this intervention, the architect Geo Lanza, into concrete reality.

The type of resin chosen for the flooring in this large open-space area creates a feeling of warmth and fluidity, in line with the exciting journey the visitors encounter during their visit to the production unit and the museum of liquorice.

The colour was expertly created in the Mapei Research & Development Laboratories, taking inspiration from a precise point in the cooking of the liquorice roots during one of the phases of the process.

The high flow of visitors, around sixty thousand every year, was a valid motive for choosing a Mapei product system with the capacity to withstand intense foot traffic.

STUNNING RESIN FLOORING WITH DECOR SYSTEM 70

Mapei’s DECOR SYSTEM 70 was chosen to make the resin flooring, a solvent-free, epoxy system applied in layers from 1.5 to 3 mm thick, which is used to create decorative floorings (including those in showrooms) with a trowel-effect finish and excellent resistance to wear.

The preliminary preparation work on the substrates was vitally important and involved the application of a layer of TOPCEM PRONTO ready-to-use, normal-setting, controlled-shrinkage mortar with high thermal efficiency for quick-drying (4 days) screeds. The mortar was applied to create an unbonded screed using a sheet to avoid rising damp. It was also reinforced at the mid-point with an electro-welded mesh.

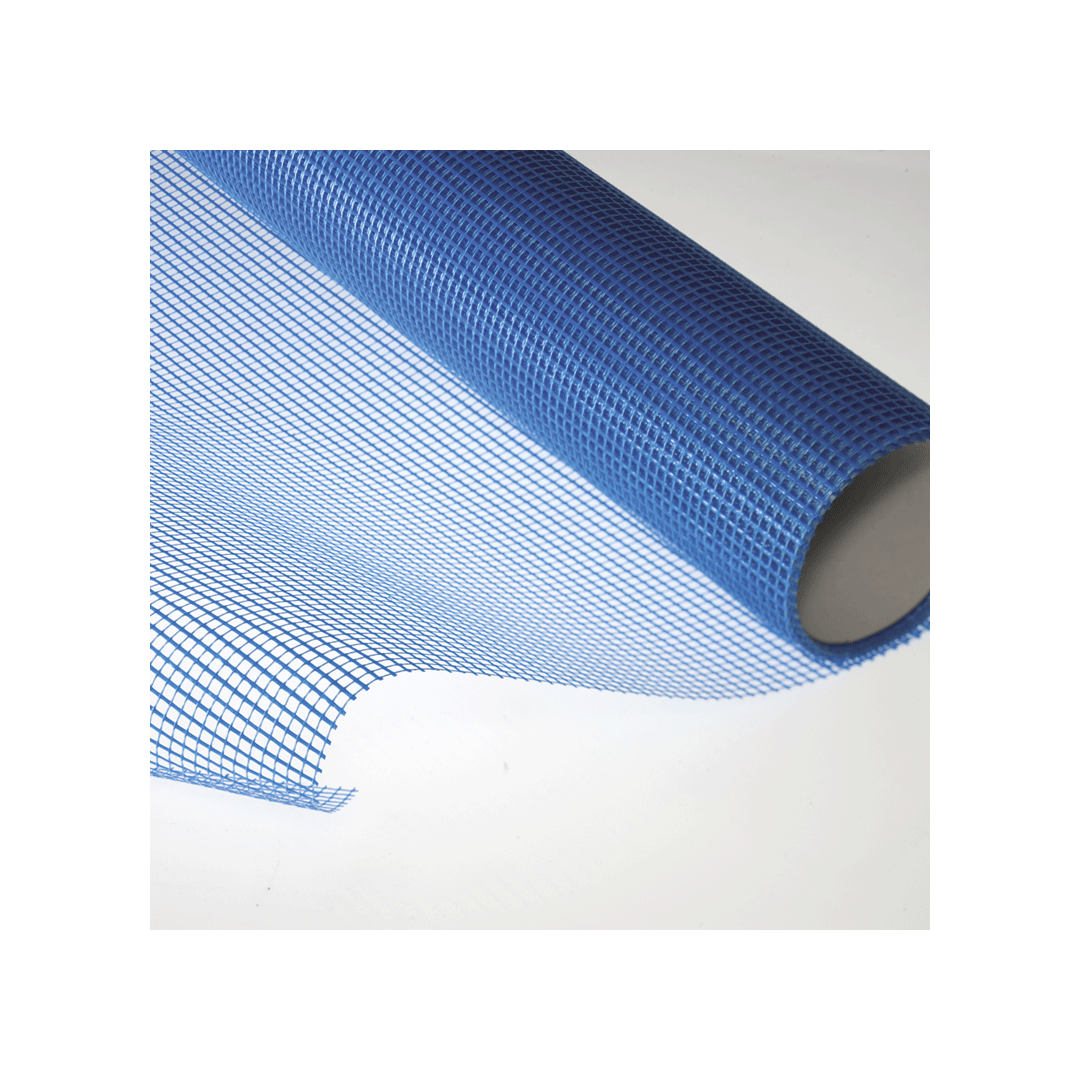

Once the specified drying time for the screed had been respected, the surface was grinded with a special grinding machine and, once all the dust had been removed with an industrial vacuum cleaner, a coat of PRIMER SN, two-component, pre-fillerized epoxy primer, was applied. MAPENET 150, alkali-resistant glass fibre mesh, was embedded in the primer and the entire surface was broadcast with QUARTZ 0.5.

After removing all the excess quartz sand, the substrate was sanded and all the dust was removed. Work then continued with the application of a second coat of PRIMER SN to completely cover the mesh and, while the primer was still wet, the surface was again broadcast with QUARTZ 0.5.

The substrate needed to be sanded down again and, after removing all the dust with a vacuum cleaner, three coats of MAPEFLOOR DECOR 700 (fillerized with 30% by weight of QUARTZ 0.25 and tinted with MAPECOLOR PASTE) was applied.

Only at this point could the “liquorice colour effect” phase be undertaken. This was achieved by applying MAPEFLOOR FINISH 58 W mixed with just the right amount of oxide, mother of pearl and silver powdered aluminium, which was spread over the surface with an American trowel and finished off with a sponge.

The final finishing steps involved the application of two coats of MAPEFLOOR FINISH 50 N with an American trowel followed by two coats of MAPELUX OPACA double-reticulating, high-strength matt metallic wax.

ULTRATOP LOFT FOR THE WALLS

In the service area, 15 m2 of walls were coated in “liquorice colour effect” using the ULTRATOP LOFT system to create decorative surfaces with a trowelled or mottled effect.

After applying two coats of PRIMER LT, acrylic primer (diluted 1:1 by weight with water) with a roller on the lime-based renders, followed by two coats of PRIMER GRIP WHITE, an American trowel was used to apply a first coat of ULTRATOP LOFT F, one-component trowellable coarse-textured cementitious paste, on the surfaces.

After sanding the substrate and removing all the dust with a vacuum cleaner, a second and then a third coat of ULTRATOP LOFT W tinted to form a “liquorice-effect” finish were applied.

After sanding the substrate again and removing the dust with a vacuum cleaner, the finishing operations were carried out by applying two coats of MAPEFLOOR FINISH 58W, matt polyurethane finish, with a short-haired (mohair type) roller. The application of MAPELUX OPACA, double-reticulating metallic wax, completed this intervention, which was carried out to perfection.