Creativity and research: a new life for “waste” materials

We spoke with Giuseppe Fallacara, curator of the "Marmomac Meets Academies" exhibition and professor at Polytechnic of Bari

Giuseppe Fallacara, curator of the "Marmomac Meets Academies" exhibition and professor at Polytechnic of Bari, describes the goals and features of the project

What is the background of the "Marmomac Meets Academies" project?

How important is collaboration between universities and companies from the stone materials sector?

What is the most interesting aspect of the project, presented by the Polytechnic of Bari and Stilmarmo as part of the “Riparti” project?

We won a project launched by Apulia Regional Council called “Riparti”, proposing the use of what is commonly thought of as “waste” from the extraction of quarried stone. The term “waste” isn’t really exact because, when it comes to stone, there aren’t any parts that are disposed of, but only parts that are used less or downgraded from an economic perspective. These have to be combined with creativity in order to be transformed into a new product. In the case of the objects on display here, thanks to the expertise of Mapei technicians and the use of specific products like the ones supplied by Mapei, we have managed to give these “secondary materials” a new life and open new scenarios.

Mapei products are present in a lot of these prototypes: in the suspended vault with engineered stone tiles representing the fixed stars, in which there are fragments of glass bottles treated with Mapei products to create both the mix and their shine; the steps of the osteomorphic staircase are elements subjected to dynamic stresses that have been made out of a 2 cm slab of stone, hollowed out and then strengthened with Mapei products; other materials from the company have been used to treat various surfaces in stone; we have used Mapei adhesives to make the “stone-insulating materials” pairing compatible. With MAPESTONE GR-ECO, a special mortar made from apple fibres, we have installed flooring with a complex geometric pattern, while with other specific mortars we have bonded thin slabs, a by-product of the stone industry, in areas of historic town centres subjected to high levels of pedestrian traffic.

Is there a coordination between Italian and overseas universities for the topic of sustainability?

How is the Polytechnic of Bari approaching this topic in order to educate the professionals of the future?

Do you have laboratories specifically for studying stone materials?

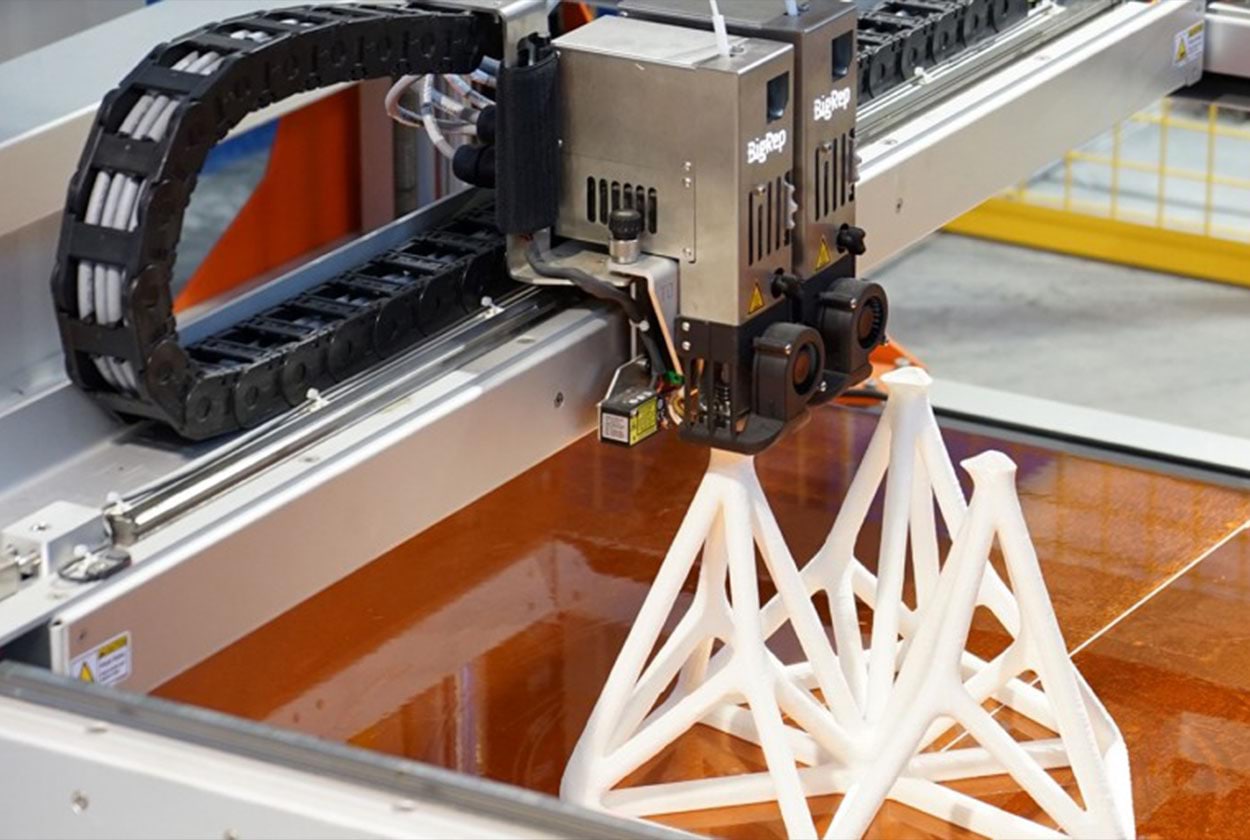

In partnership with our colleague Nico Parisi from Bari Polytechnic University, we have managed to give concrete form to the dream we have always had of having our own research laboratory. Nico Parisi is now the director of one of the largest laboratories in Italy devoted to stone materials, so we can turn teaching into something more than just theory. The person teaching is part of a research group that includes students working on a hands-on basis in a laboratory. Manual expertise is a kind of intelligence that passes from hand to brain as you actually go about your work. Students of architecture and industrial design must get their hands dirty and be "materialistic" in the positive meaning the word, i.e they must be familiar with every core aspect of a given material, so they can treat it with the respect it deserves.

Getting our hands dirty is the only possible way to get Italy back to that workshop-focused approach that characterised the Renaissance. Combining practice with theory is what we are really trying to do at FabLab, and the results are outstanding: the students are delighted, they are the first in through the lab doors in the morning and the last to leave in the evening and, drawing on all their creativity, they manage to find solutions to even highly tricky technical issues.