Research & Development

/

2/21/2024

The challenge of low-clinker cements

Innovate solutions for carbon neutrality from cement to concrete

The production of cement is one of the main sources of CO₂ emissions: it is estimated that it contributes to 8% of global emissions. To achieve carbon neutrality by 2050, the cement industry is implementing various actions. Among them, the most rapidly effective one is the reduction of the clinker content of the cements

How to achieve carbon neutrality by 2050?

In recent years, the cement industry has been facing new challenges related, above all, to the need to reduce CO2 emissions to achieve carbon neutrality. The production of cement is one of the main sources of CO2 emissions: it is estimated that it contributes to 8% of global emissions. They are produced by the decarbonation of calcareous minerals used to produce clinker and by the large quantities of fuels necessary to reach high burning temperatures. Overall, it is estimated that for each ton of clinker, approximately 0,85 tons of CO2 are produced and emitted into the atmosphere.

To achieve carbon neutrality by 2050, the cement industry is implementing various actions. These include, for example, increase of use of alternative fuels, reduction of clinker to cement ratio, use of natural gas and hydrogen, use of alternative raw materials, carbon capture, usage and storage, renewable energy and efficiency, local supplying and green transports.

Among these actions, the most rapidly effective one is the reduction of the clinker content of the cements. Currently, in Europe the average clinker/cement ratio is around 0,75: to significantly contribute to neutrality it is estimated that it will have to be reduced to 0,65.

Opportunities of the current standards

To a certain extent, a reduction in clinker/cement can be achieved with the types of cement classified according to European standard EN 197-1. Thanks to the optimization of the chemical-physical characteristics of the cements and, above all, the use of specific additives, it is often possible to obtain significant reductions of 3-4% of clinker while maintaining the same performance of the cement. However, if we consider the cements mostly used to produce concrete (CEM I and CEM II/A-L), it is not possible to further lower the clinker/cement ratio. EN 197-1 also allows making greater use of composite cements in the production of concrete: this enables a strong reduction of the clinker/cement ratio. For example, pozzolanic cements with natural pozzolana (P) are an alternative that can be exploited in various parts of the world by taking advantage of the pozzolanic activity of sands of volcanic origin.

A further step in this direction took place in 2021 with the publication of the EN 197-5 standard in which new composite and ternary cements with very low clinker content are classified. The use of these cements would make it easier to achieve the objectives of carbon neutrality. For example, limestone-calcined clay-based cements fall within this standard.

Finally, European standard EN 197-6, which was published in 2023, introduces the possibility of using recycled concrete fines as a supplementary cementitious material which, within certain limits, behave like limestone. The use of this new component allows to reduce the consumption of natural raw materials and waste to be sent to landfill. It is therefore part of a broader circular economy program for concrete.

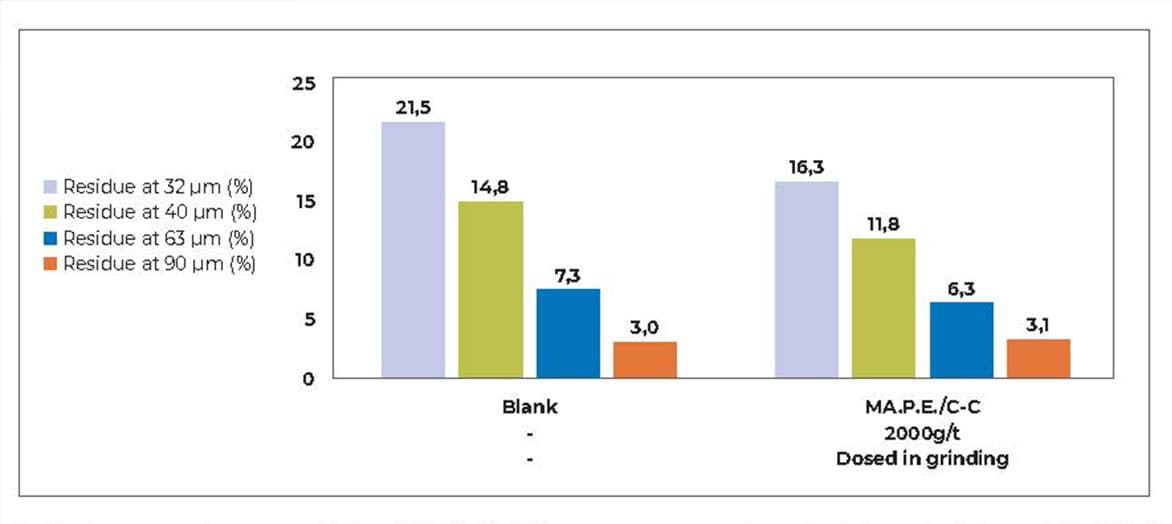

1. Air-jet granulometry of the CEM IV/A (P) cement reproduced with and without MA.P.E./C-C.

Issues related to the low-clinker cements

Alongside the environmental and economic benefits associated with lower clinker/cement, concretes produced with blended cements can also have improved properties. For example, cements containing pozzolanic materials such as natural pozzolana or calcined clay, can lead to a greater resistance to external attacks and, consequently, greater durability.

Unfortunately, the use of this type of cements frequently presents critical aspects related, above all, to the high specific surface and the high adsorbing capacity of the supplementary cementitious materials. These characteristics can lead to a higher demand for water, a loss of workability of the fresh concrete and a loss of the effectiveness of the superplasticizers used in the concrete production.

Flow test used to assess the workability of cements.

The new MA.P.E./C-C cement additives

To mitigate the issues related to the low-clinker cements, Mapei has developed a new range of cement additives called MA.P.E./C-C (from Cement to Concrete). These additives have the peculiarity of, beside improving the grindability and mechanical performance of cement, lead to an enhancement of the workability both in mortar and concrete application.

In this article, some significant examples are shown to prove their effectiveness.

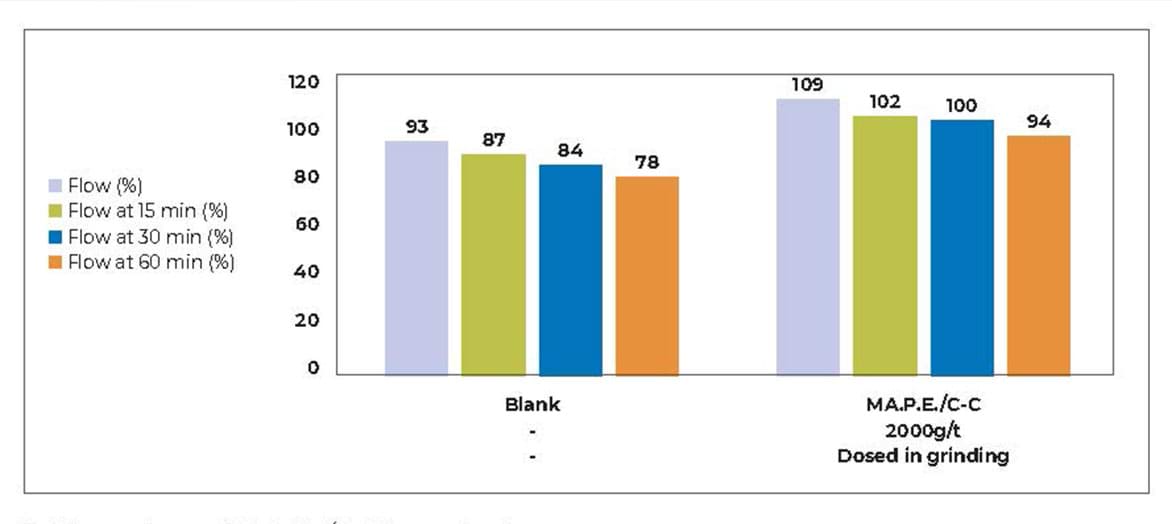

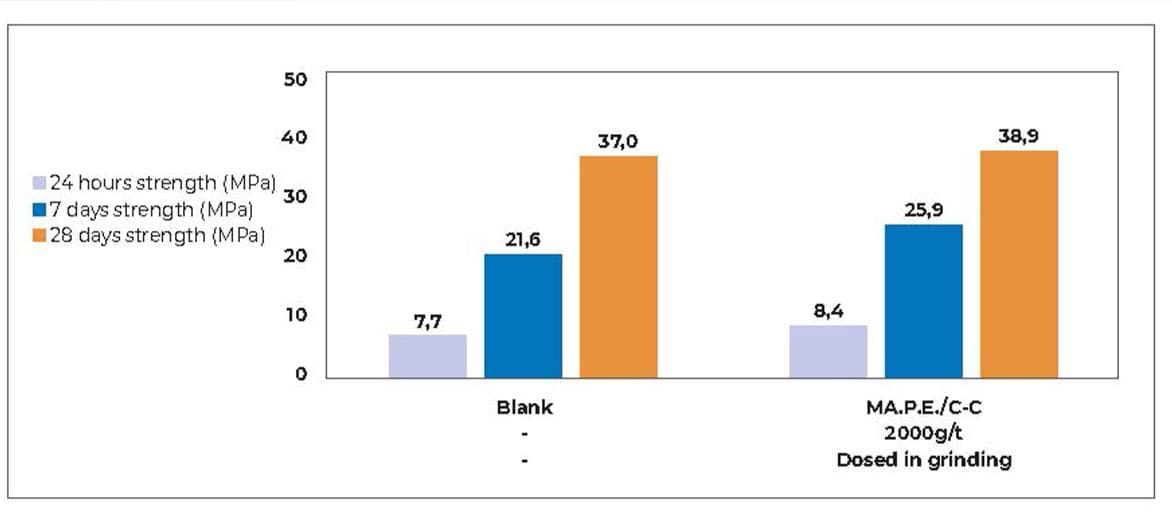

2. Flow values of CEM IV/A (P) standard mortars

Improving the quality of a pozzolanic cement

The first example deals with a pozzolanic cement, CEM IV/A (P) according to EN 197-1. The pozzolana available in the cement plant is highly active but has the defect of absorbing a lot of water due to its high specific surface. This feature causes a high demand for water and poor workability in concrete applications, which make it extremely difficult to use.

The cement has been reproduced according to the industrial recipe (69% clinker, 4% gypsum, 27% pozzolana) in the Mapei Research & Development laboratory, with and without dosing MA.P.E./C-C during grinding in laboratory mills.

The fineness of the laboratory cements has been estimated by the air-jet sieving method according to EN 196-6 standard. The results are shown in Figure 1. MA.P.E./C-C additives have made it possible to significantly improve, at a same grinding time, the fineness of the cement thanks to the introduction of specific components in their formulation. MA.P.E./C-C will therefore be able to reduce the energy required to produce cement or else increase the production rate keeping the same energy consumption.

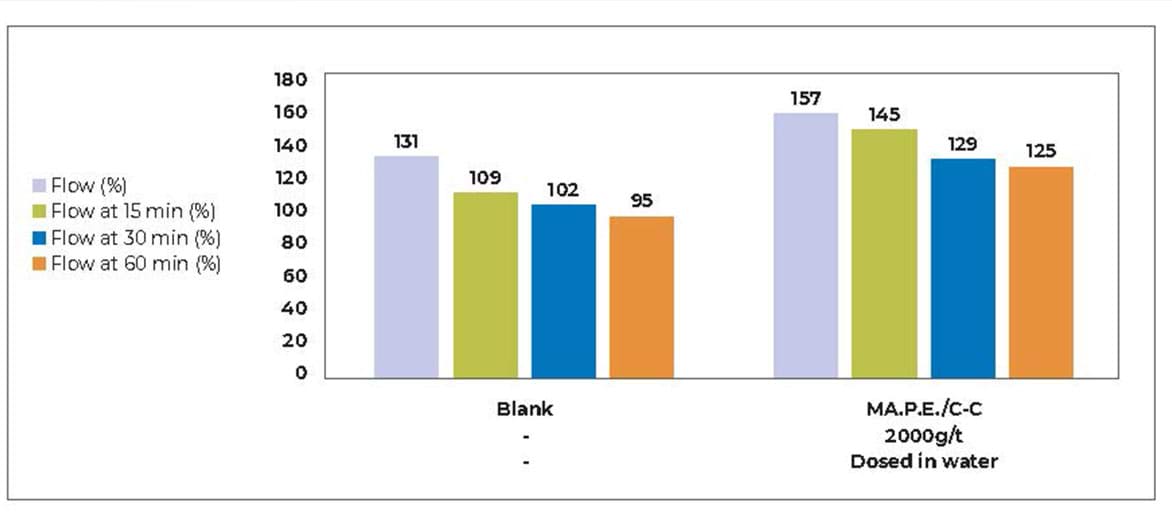

The main problem of the cement is its bad workability which is mainly due to its high adsorption of water. Workability of cements has been assessed on a standard mortar according to EN 1015-3.

With this method, a flow value is determined from the increase in diameter of a fresh mortar specimen, placed on a specific table using a mould, to which a given number of vertical impacts are applied by lifting the table and letting it fall from a given height.

The test has been repeated at fixed times from the mixing to assess the loss of workability during time. As shown in Figure 2, MA.P.E./C-C has allowed to greatly increase the initial workability. Moreover, it has maintained the workability over time with a flow value that, after 60 minutes, is still higher than the initial flow value of the blank sample.

It is well known that sometimes performance of concrete is different from those obtain from mortars. For this reason, to simulate the effect in concrete application, the same tests have been performed on Cement Equivalent Mortars (C.E.M.). These mortars, whose composition is deduced from that of concrete, have rheological properties very similar to those of concrete. To prepare C.E.M. without supplementary use of concrete additives, it was decided to work with a high amount of water (w/c=0,61) to simulate semi-fluid concretes. The results, shown in Figure 3, have confirmed those obtained on standard mortar: an increase in the initial flow value and its maintenance over time. These are clear indications that MA.P.E./C-C can increase workability both in mortar and concrete application.

Figures 4 and 5 show the effect of MA.P.E./C-C on the development of mechanical strength for the same mortars described above.

The addition of MA.P.E./C-C has allowed to enhance the performance in every mortar condition and for every curing time. This characteristic will reasonably allow to improve the production process of the pozzolanic cement by reducing ulteriorly the clinker/cement ratio or reducing the fineness.

3. Flow values of CEM IV/A (P) Concrete Equivalent Mortars (C.E.M.).

Improving the quality of a special cement

The second example relates to a special cement produced by replacing around 50% of clinker with a secondary raw material to considerably reduce the specific emission of CO2.

The secondary raw material used for this cement is a blend of calcined clay and recycled inert minerals characterized by a high porosity that leads to a high request of water. Consequently, the cement shows a noticeable loss of workability and an increase of viscosity of the fresh concrete, which make it difficult to use it in concrete applications.

For this type of cement, the use of

MA.P.E./C-C additives was tested on an industrial cement by adding them in the mixing water of standard mortars with an increased water/cement ratio (w/c=0,6).

As shown in Figure 6, MA.P.E./C-C additives have allowed to greatly increase the initial workability of the industrial cement and to maintain it over time, with a flow value that, after 60 minutes, is still in line with the initial flow value of the blank sample.

The viscosity of the mortars has been tested using a rheometer equipped by the so-called “ball measuring system” at a shear rate of 1s1. . The evolution of viscosity has been monitored for 60 minutes from the mixing of the mortars.

The results have confirmed the increased fluidity of the mortar with MA.P.E./C-C cement additives. Moreover, MA.P.E./C-C maintain a low viscosity of the fresh mortar over the time: viscosity at 60 minutes from the mixing is lower than the initial viscosity of the blank sample.

4. Mechanical strength of CEM IV/A (P) standard mortars.

MA.P.E./C-C: a sustainable technical solution

These examples demonstrate that MA.P.E./C-C, the new range of cement additives developed by Mapei, can help cement producers and users in the most difficult cases, thanks to the combination of numerous benefits: increased grinding efficiency, improved workability in mortar and concrete, increased mechanical strength.

Moreover, they show the versatility of these new additives: they can be used in the case of a high substitution rate of clinker with materials that, under normal conditions, would lower the quality of the cements making it very difficult to use.

MA.P.E./C-C additives make it possible to solve these problems and represents an answer to the challenge that the cement industry has to face in the coming decades.

In fact, these additives can make it possible to produce cements with a lower clinker content, lower production costs, lower CO2 emissions and with a higher quality, whose effects will be noticed in the applications of both mortars and concrete.

5. Mechanical strength of CEM IV/A (P) Concrete Equivalent Mortars (C.E.M.).

A dedicated division for the cement industry

In 2000 Mapei introduced the “Cement Grinding Additives” line, products dedicated to cement production with the visionary idea of helping the Construction Industry become a carbon-neutral industry starting from its main raw material: cement. These additives are meant to be used during the cement production process, to support the cement industry on the roadmap to produce modern cements with zero CO2 emissions.

When Mapei first approached this market, only traditional Grinding Aids were available: additives that are mainly formulated to solve agglomeration problems within cement mills and reduce electrical energy consumption. Since then, many innovations have been brought onto the market by Mapei Research & Development laboratories, evolving form the original Grinding Aids to the most advanced MAPE C-C additives, a real “bridge” between cement and sustainable and durable concrete.

Find out more https://cadd.mapei.com/en/

6. Flow values of the special cement standard mortars with and without MA.P.E./C-C.