Cementos Argos: Sustainability is one of our pillars

We spoke with Diego Mesa, Manager of improvement and development at Cementos Argos, about sustainability and the concrete industry

The Manager of improvement and development tells us more about the Argos Cementos Group's goals and measures to ensure a more sustainable production of cement and concrete

How important is sustainability for your company?

What concrete actions are you taking to achieve this goal?

How do you manage to combine the goal of obtaining more sustainable cement and concrete with the commitment to your customers to supply products with high-performance properties?

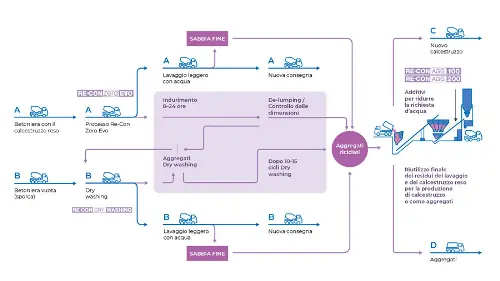

We invest heavily in the analysis and optimization of the entire production process, and strive to ensure that the best raw materials and technologies are used to improve our processes and products. That's why we need excellent partners, like Mapei, who can help us achieve this goal. For example, we are evaluating the development of mix design using MAPECUBE system solutions (super-plasticizing admixtures, strength enhancers, automation of the concrete production chain) that allow the amount of clinker in the cement to be reduced, while guaranteeing the performance properties of a mix design. We are already using Mapei solutions such as DYNAMON SR33 (super-plasticizer to obtain concrete mixes with low water/cement ratio, extremely high mechanical strength and long slump retention), as well as high-performance grinding aids such as MA.G.A. /C 095, MA.P.E/S 785, and MCH 295 to increase mill production and improve the cement quality. Alternative Raw Materials (ARM) and sustainably managing waste from the concrete production process in an effective way, we are also very interested in the solutions from the RE-CON Line.

CEMENTOS ARGOS

With more than 80 years of history, Cementos Argos is the largest cement and concrete manufacturer in Colombia and one of the most important manufacturers in the United States, the Caribbean and Central America. This large multinational has an established presence in 16 countries, almost 7,000 employees, 11 cement plants, 197 ready-mix concrete plants, 9 grinding mills and 7 aggregates plants. Argos has a total installed capacity of 24 million tons of cement per year, 6.2 million tons of cement delivered and 7.5 million m3 of concrete shipped, and exports to 25 countries.

Find out more about Mapei solutions for the concrete industry at: https://www.mapei.com/cis/en/home-page