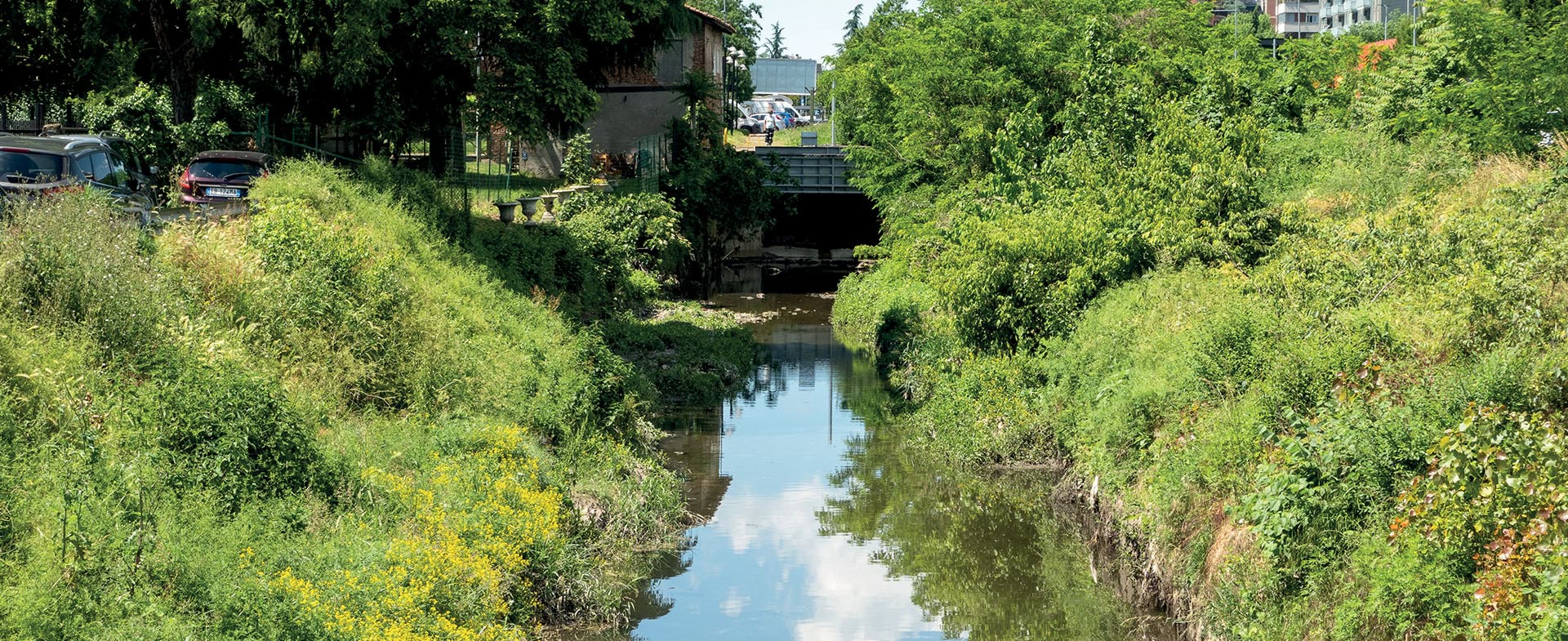

Cavo Redefossi sewer

A bespoke fibre-reinforced mortar employed for consolidating a masonry canal used as sewer.

A bespoke fibre-reinforced mortar employed for consolidating a masonry canal used as sewer.

An ancient man-made canal

The Cavo Redefossi is a man-made canal that flows mainly underground through Milan, receiving water from the Naviglio Della Martesana canal and River Seveso before flowing into the River Lambro. It probably already existed in Roman times and was rebuilt between 1783 and 1786 by the Austrian government, which decided to re-route the canal to prevent the River Seveso flooding the Porta Romana, Porta Vittoria and Porta Lodovica districts of the city.

The start point of the canal is in the Porta Nuova district, near the Gabelle Bridge. From here, it flows underground through Porta Venezia district in an easterly direction, through the neighbourhoods of San Donato Milanese and San Giuliano Milanese before arriving in Melegnano, where it flows into the Vettabbia Canal and then into the River Lambro.

The Cavo Redefossi canal was roofed over for the 1906 Expo when it was decided to build several new hotels. The work to roof over the canal included the construction of a supporting wall for the roof running along the centre of the canal, which was made from concrete.

.jpg?sfvrsn=526f4c8e_5)

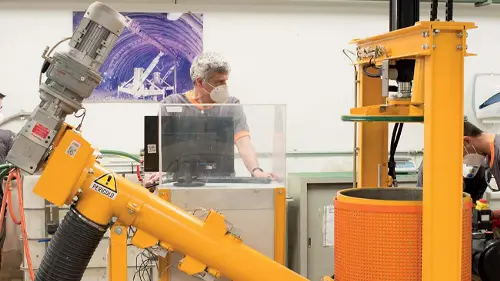

Consolidation works

The Cavo Redefossi sewer is around 2.5 km long and is one the many hidden underground passages in Milan. To ensure the water is able to flow freely without obstruction, including in periods when the flowrate is particularly high, it had become necessary to carry out consolidation and maintenance work.

The walls of the canal had become unstable and had cracks which had spread to the vaulted ceilings, due to the effect of mechanical action of the loads and stresses generated by the traffic passing above. There was also evidence of leaching phenomenon, that is, the water flowing along the canal had dissolved the soluble substances present in the ground and the mortars the water had come into contact with. It was essential, therefore, to carry out significant repair work on the vaulted ceilings, the piers and the bed of the canal.

Mapei proposed MAPEGROUT FMR-PP, a thixotropic, fibre-reinforced mortar used to repair and strengthen concrete structures, and ideal in those cases where, apart from a high level of ductility, good resistance to sulphates and alkalis is also required, such as in repair work on sewer systems and tunnels. Thanks to its structural polymeric fibres, it maintains its high resistance to flexural loads and stresses even after the onset of cracking in the cementitious mortar.

To repair the vaulted ceiling, the first step was to hydro-scarify the surface to create a solid, resistant and rough substrate. The substrate was then saturated with water. Once the water had evaporated off, a layer of MAPEGROUT FMR-PP was applied by spray. Once this layer had dried, steel mesh was applied on the surface and then covered with another layer of MAPEGROUT FMR-PP for a total thickness of 20 cm.

The new vaulted ceiling, repaired as described above, is now able to absorb all the structure’s static loads.

.jpg?sfvrsn=516f4c8e_5)

.jpg?sfvrsn=5e6f4c8e_5)

.jpg?sfvrsn=506f4c8e_5)