The new Museum of Ethnography in Budapest, part of the Liget Budapest Project, incorporates Mapei solutions for waterproofing its unique concave roof, installing ceramic and stone tiles, and varnish wooden floors. This modern building blends cutting-edge technology with architectural beauty.

The Museum of Ethnography in Budapest is one of the most important museums of its kind at European level: it houses the biggest collection in the region of ethnographic objects representing the folk cultures of both Hungary and people from other countries and continents. Next to a collection of 225,000 ethnographic objects, its holdings include photographic and film materials, manuscripts, and folk music recordings.

With the inauguration of its new building in the spring of 2022, the museum has become one of the most modern ethnographic museums in the world. The new building, designed by Napur Architect, was constructed on Ötvenhatosok tere (Square of the ‘56ers) as part of the Liget Budapest Project, which is currently Europe's largest urban development project and aims to enrich Hungary by large-scale cultural and landscape architecture investments.

Below ground level, the almost 7,000 m2 of exhibition space host both temporary and permanent displays. The first floor houses a bookshop, a restaurant, a library, a documentation centre, co-working facilities, a visitors’ centre, an events centre, and an interactive museum for children, making the museum one of the most important cultural hubs in Budapest.

The project for the new building was voted for the "Best Mega Futura Project of Europe" at the MIPIM Awards 2017 and has won the title of "World’s Best Architecture" at the 2018 International Property Awards.

The new building of the Museum of Ethnography in Budapest, designed by Napur Architect, is a one of the most important cultural hubs in Budapest. Photo credit: Liget Budapest.

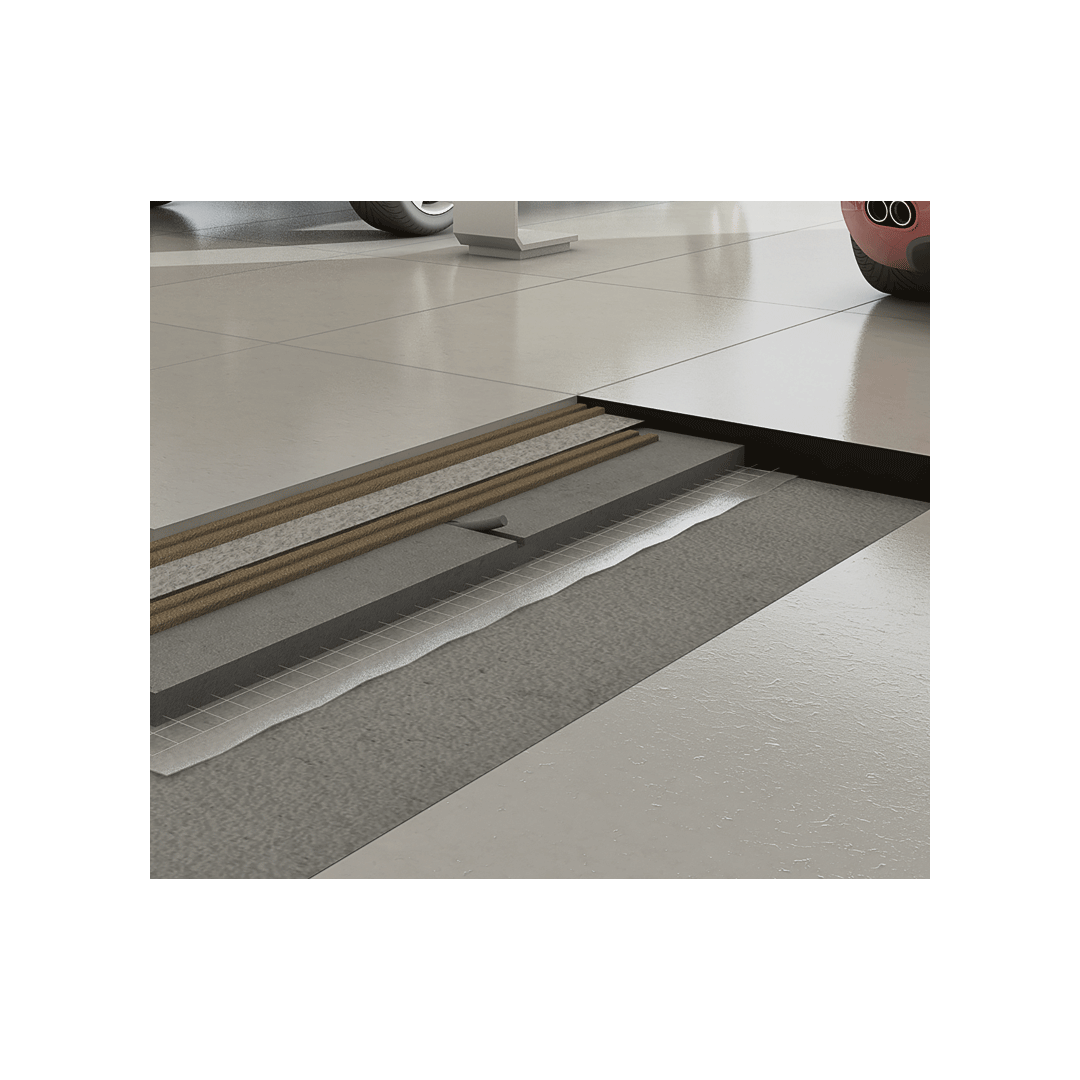

The building's architectural style is determined by the negative arch-shaped roof, which has a paved middle that touches the ground and both ends planted with vegetation that curve upwards. The rooftop, in addition to being a protective outer shell, also works as a public park, with lush greenery and paved surfaces. Creating and covering this unusual, curved roof slab required considerable effort from the designers. Prior to the installation of the waterproofing layer, the quality of the concrete substrate had to be tested and locally repaired before creating an inclined plane in the horizontal middle section of the otherwise arched roof. Roof-harvested rainwater is diverted into downpipes to the inside of the building. The grade at both ends of the curved roof reaches 29%, so it was very important to safely secure all waterproofing and insulating layers. The sloping sections of the roof were primed with MAPEFLOOR I 914 two-component epoxy protective coating, and covered with a layer of ELASTOFLEX HP 5 mm elastomeric polymer distilled bitumen waterproofing membrane applied by torching onto the whole surface. The installation of a layer of ANTIRADICE FLEX P elastomeric polymer distilled bitumen waterproofing membrane allowed to create a root barrier.

The installation of a layer composed of 20 cm thick, XPS (closed-cell) polystyrene foam boards of high compressive strength came next, to ensure excellent moisture absorption.

The roofs of the new building were waterproofed with membranes supplied by Polyglass (Mapei Group).

Installing ceramic tiles and stone in the interiors

Ceramic and stone floor coverings contribute enormously to the elegance and stylish appearance of all interior spaces of the new building. Mapei products were used for installing ceramic and stone tiles on a total surface of 7,000 m2.

On stair treads, MAPESONIC CR soundproofing membranes were installed with ULTRABOND V4SP universal adhesive. Andesite tiles were bonded onto the stair treads with KERAFLEX MAXI S1 deformable cementitious adhesive, which is now available on the international market as KERAFLEX MAXI S1 ZERO*. In many interiors of the museum, the floor substrates were treated with PRIMER G synthetic resin-based water-dispersion primer. Distribution joints were overlapped with MAPETEX SYSTEM anti-fracture membranes, to prevent cracks in the substrate being transmitted into the new ceramic coverings. MAPETEX non-woven membranes were bonded with ULTRALITE S2 cementitious adhesive, prior to installing the tiles using the same product.

KERAFLEX MAXI S1 was also used to bond ceramic tiles on several floors of the museum. Tile joints were grouted with ULTRACOLOR PLUS anti-efflorescence, quick-setting and drying polymer-modified mortar, whereas expansion joints were sealed with neutral MAPESIL LM silicone sealant, which is especially suitable to avoid the formation of stains on stone surfaces.

Ceramic tiles were also installed onto plasterboard surfaces in the kitchens and bathrooms of the complex. The substrates were first treated with PRIMER G and levelled with NOVOPLAN MAXI cementitious levelling compound. 10 × 10 cm ceramic tiles were then laid with ADESILEX P9 adhesive with no vertical slip and extended open time.

The areas of the substrates were waterproofed with MONOLASTIC one-component cementitious waterproofing mortar which is now available as MONOLASTIC ZERO* with fully offset CO2 emissions*. Tile joints were grouted in various color shades with KERACOLOR FF FLEX**, a cementitious mortar manufactured and distributed on the Hungarian market by Mapei Kft., whereas expansion joints were sealed with MAPESIL AC silicone sealant.

Andesite tiles were installed onto the stair treads with KERAFLEX MAXI S1 adhesive (now available as KERAFLEX MAXI S1 ZERO*).

Wooden floors in the exhibition spaces

In the exhibition spaces, the use of natural, soundproof floors was an important request from the owner, besides durability and future renewability of the surfaces.

So interior designers opted for parquet. Because of the large surfaces to be covered, acclimatising materials and treating the freshly laid floor with a highly protective lacquer were also extremely important. This is why Mapei recommended the use of a complete system to prepare and varnish wooden floors exposed to high levels of pedestrian traffic.

After sealing and priming the wooden surface with ULTRACOAT BINDER and ULTRACOAT UNIVERSAL BASE, ULTRACOAT HT 2K water-based lacquer worked perfectly, allowing wood floor shine with the natural light coming from the windows.

A complete Mapei system was used to prepare and varnish wooden floors exposed to high levels of pedestrian traffic.

New building, Museum of Ethnography, Budapest (Hungary)

Owner: Városliget Zrt.

Period of the construction: 2020-2022

Design: Napur Architect Kft., Marcell Ferencz

Period of the Mapei intervention: 2020-2022

Intervention by Mapei: supplying products for waterproofing roofs, installing ceramic and stone tiles, treating and protecting wood floor, laying resin floors

Main contractors: Consortium of ZÁÉV Építőipari Zrt. and Magyar Építő Zrt.

Contractor for waterproofing: Lajtaszig Kft.

Contractors for tile installation: Stukkó Kft., Dominó Kft.

Contractor for wood floors: Metisystem Kereskedelmi és Szolgáltató Kft.

Contractor for resin flooring: Vasi Épker Kft.

Mapei distributors: Stukkó Kft., Domino Kft., Meti-System Kereskedelmi és Szolgáltató Kft., Balázs Szakály SP

Mapei coordinators: Júlia Fleisz, András Ipacs, Sándor Nagy and István Bíró, József Ladics, Mapei Kft. (Hungary)

Photos: Városliget Zrt., Tibor Soós, Liget Budapest

*CO2 emissions measured throughout the life cycle of products from

the Zero line in 2024 using Life Cycle

Assessment (LCA) methodology, verified and certified with EPDs, have

been offset through the acquisition

of certified carbon credits in support

of forestry protection projects. A commitment to the planet, to people and

to biodiversity.