The expert's opinion

/

4/27/2023

A full proposal with a new product line

Concrete flooring solutions: innovative solutions for durable concrete flooring.

Concrete flooring solutions: innovative solutions for durable concrete flooring.

CFS, the Concrete Flooring Solutions

E-commerce and online shopping, and then the pandemic, have profoundly changed the way we shop. Large quantities of goods are moved around the world and arrive effortlessly in our homes. And this is a global phenomenon.

Those large logistics hubs we see springing up around major motorway junctions play a vital role in this process. Inside these structures one of the most important components is the concrete industrial floor.

Vertical racking carrying heavy loads and the frequent passage of forklifts means the floors require special attention when being designed and installed.

To meet this growing demand, Mapei decided to put a team of experts out in the field: which is how the Concrete Flooring Solutions (CFS) line was born. The word "solutions" is the very essence of this proposal: it does not just mean selling products but working alongside our clients to propose solutions.

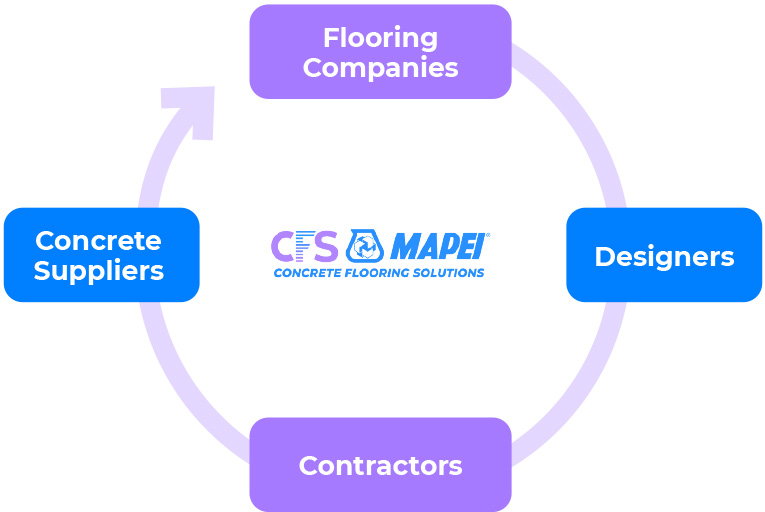

The new line is aimed at designers, general contractors, construction companies and, last but not least, those who install flooring: the professionals who find themselves having to analyse a civil or industrial construction project that involves the installation of a concrete floor.

Mapei does not want to limit itself to being just a supplier, but rather a reliable partner who you can turn to for concrete solutions for all your various construction needs.

Large quantities of goods are moved around the world. Those large logistics hubs around major motorway junctions play a vital role in it. Inside these structures one of the most important components is the concrete industrial floor.

Concrete Flooring Solutions is aimed at designers working in the logistics sector, as well as flooring contractors and manufacturers of concrete.

Support in design and product selection

Guidelines issued in many countries and international standards consider an industrial floor to be a structural element and, as such, must go through a design process.

Mapei’s CFS offers its clients support during the design phase, which could consist in our Design Team simply calculating the proper dimensions, right up to providing a complete structural design: in such cases we also turn to highly experienced external consultants.

An industrial floor is similar to a made-to-measure suit: it needs to be tailor-made and adapted to the needs of its specific function once in service and to the requirements of the client. In this phase we supply an optimised solution from a cost/benefit perspective, which is also verified structurally according to current applicable standards.

The second step is choosing the products and qualify the materials: we work alongside the flooring contractor and the supplier of the concrete to study the most suitable mix, favouring the use of fiber-reinforced concrete and controlled-shrinkage concrete for jointless floors: putting our know-how at the service of the client.

And with our constant focus on the wellbeing of the environment and people, Mapei continues to make an important contribution to a building sector increasingly focused on the health of the planet: synthetic fibers improve the durability, ductility and fatigue behaviour of concrete and guarantee a reduction in CO2 emissions.

The third but no less important phase is on-site checks and controls. Thanks to our Mobile Concrete Labs we are able to carry out checks on fresh concrete: this operation has the twin scope of making sure it corresponds with what was specified in the qualification phase and to intercept potential anomalies in the concrete.

We also organise training courses and workshops at various knowledge levels for our clients.

Within the comprehensive range of products for industrial floors, the new line proposes not only fibers for structural use and super-plasticising admixtures, but also dry-shake hardeners made of special well-graded quartz, anti-evaporation products, lithium silicate surface treatments and products to create contraction joints.

An increasingly specialised market requires long-lasting solutions with low maintenance costs: MAPECRETE SYSTEM, the innovative solution by Mapei for jointless floors is the answer to this need.

Placing concrete to create an industrial floor with an underfloor heating system.

Not only floors for the logistics sector

Concrete Flooring Solutions supplies products and support not only to create concrete industrial floors for the logistics sector, but also for a whole host of applications, such as:

- coatings for hydraulic channels

- concrete roads inside tunnels

- pavements and cycle lanes

- airport applications

- mooring docks

- extruded components for roads

- architectural floors.

The approach is always the same: supplying a design according to scope, choosing the right products and supporting the client during the execution phase.

Smoothing the surface of the floor using a helicopter-type power float.

A new manufacturing plant for fibers

Manufacturing output has doubled since Fili&Forme was taken over in 2018.

It was 4 April 2018 when Mapei took over Fili&Forme Srl, a company specialising in the extrusion of plastic materials for the manufacture of monofilaments for the household articles industry and synthetic fibers for concrete. The latter, also known as structural fibers, are a new technology for concrete and are used to partly and, in some cases, totally replace conventional metal reinforcements.

They are used for various purposes such as industrial flooring, pre-cast concrete elements, shotcrete in tunnels, etc. Mapei, a trailblazer in new technologies, has fully grasped the potential of this product and decided to invest in it. In accordance with its vocation for being a global supplier of miscellaneous products, Mapei has included these fibers in a number of its product ranges, and they are now distributed in over 30 countries worldwide.

Just 6 years later, giant steps have already been taken: production output has more than doubled thanks to investments in new ranges of extrusion products; Quality, Environmental, Health and Safety systems have been awarded certification in compliance with ISO 9001, ISO 14001, ISO 45001 standards and, most significantly, a modern new manufacturing plant has been bought in San Cesario sul Panaro (Central Italy). In addition to the 8,000 m2 of existing buildings, 10,000 m2 of manufacturing premises, 2,200 m2 of offices and over 15,000 m2 of outdoor areas have been added on.

Fiber manufacturing is a continuous operation spread over three daily eight-hour shifts working six or even seven days a week.

The new plant is located just a stone’s throw from the old Fili&Forme headquarters and can handle any future expansion to fiber-manufacturing business.

With an eye for sustainability, it was decided to install a photovoltaic system on the roof with a power rating of 417 kWp, that can offset tons of CO2 per year; the same type of investment is planned for next year on the roofs of the old buildings.

The M+ warehouse and logistics centre have also been moved to the new site: the company was founded in 2008 and has been part of the Mapei Group since 2010. M+ markets mosaic materials for wall and floors and offers qualified technical support for designers and customers throughout the entire life cycle of projects: from the original design to the choice of ideal materials right down to the final details, working alongside experts to come up with and develop the best solutions for domestic, business and public settings.

Over 60 staff are currently employed in the Group’s facilities in San Cesario sul Panaro.

This plant will make Mapei an increasingly significant player in Central Italy, joining forces with the company facilities in Sassuolo and the Group’s subsidiaries Cercol and Adesital.

Some pictures of the Mapei manufacturing plant in San Cesario sul Panaro (Italy) devoted to manufacturing fibers.