Re-con Zero – Returned concrete with zero impact

The use of sustainable, durable materials is becoming an increasingly real need since the consumption of the natural resources available must be reduced. Over the last few years, all those operating in the concrete sector have become increasingly sensitive to the theme of “sustainable building”, whereby a great deal of attention is paid to the life cycle of a “from cradle to grave” structure. This approach is known as Life Cycle Analysis (LCA) and adopts analysis processes, such as LEED, Itaca or similar, so that a structure, material or type of concrete may be certified on a voluntary basis as sustainable.

The main objective is to reduce the impact a structure or building has on the environment, from the design phase right up to the actual construction phase, by providing all the stakeholders in the building process with guidelines to help potential bidders monitor the work, and by giving clear indications of the environmental characteristics required by those issuing tenders. In the case of concrete, recycled material regards mainly recycled aggregates from demolished buildings and aggregates from excavated material, but also from recovered waste concrete generated during the actual production process.

Recycled materials are obtained by processing inorganic materials previously used in construction work. For this reason, their physical and performance characteristics are often inconsistent over time and they may have an influence on the performance characteristics of concrete. Often, the use of recycled aggregates means considerably more water is required for the mix and it is difficult to maintain workability of the concrete due to it being more porous, and because of the higher amount of fines contained in the aggregates. The presence of recycled aggregates in a concrete mix must be taken into consideration when designing the mix and it is important, therefore, to adopt the most innovative solutions in order to achieve the best results. To meet the needs of concrete manufacturers who encounter problems associated with the use of fine aggregates on an increasingly regular basis (recycled materials or aggregates containing clay), Mapei has developed the RE-CON line, a series of products specifically developed to mitigate the negative effects of using recycled materials.

The current RE-CON line includes the following: This absorption-inhibiting liquid admixture, if used in combination with a super-plasticising admixture from the DYNAMON line, allows for better control of the increased amount of water required when using recycled aggregates and/or aggregates containing clay, bringing, therefore, the water/cement ratio back within the design limits. Super-plasticising and absorption-inhibiting admixture. Thanks to its combined action of reducing the amount of water required and controlling the absorption rate, when using recycled aggregates and/or aggregates containing clay, it brings the water/cement ratio back within the design limits.

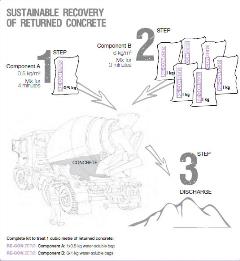

Two-component powdered product to recover returned concrete. This system allows fresh concrete returned from the site, which would normally have to be scrapped, to be transformed into new material that can be used again without producing waste. The new aggregate may then be used to partially replace normal aggregate or as material to form roadbeds or subgrade.

For more details, please contact

Mapei Construction Products India Pvt. Ltd.

A01, B01, Solus Jain Heights, 1st Floor

J C Road, 1st Cross,

Bangalore 560 002

Ph.: 080 22221820 / 22221840

Email: [email protected]

Website: www.mapei.in

Comments

Load more comments