The use of sustainable, durable materials is becoming an increasingly real need, since consumption of the natural resources available must be reduced.

A sustainable approach is to improve the durability of concrete to reduce maintenance cost, save energy and materials. If we could extend the service life from 50 years to 150 years or more, we could postpone for 100 years the costs connected to the consumption of natural resources.

Concrete can be made more durable by reducing the permeability of hardened concrete. As per ACI 212.3R.10, Permeability Reducing Admixtures or PRA’s are classified in three classes.

Further to the above admixture classes, the ACI 212.3R.10 describes these admixtures as:

Idrocrete KR 1000 a powder admixture made from special hydrophilic components which, when added to a concrete mix, reduces the permeability of hardened concrete.

This crystalline based admixture is categorized as PRAH and hence resists water penetration under pressure.

Laboratory tests have shown that adding Idrocrete KR 1000 to

concrete reduces its level of capillary absorption and makes it more resistant to the hydrostatic pressure.

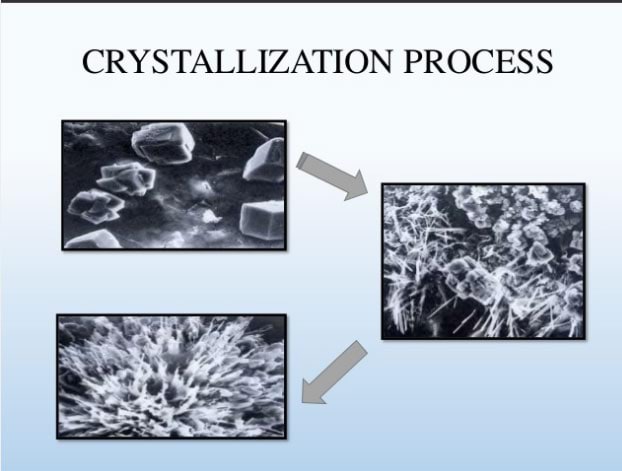

MECHANISM: On adding water to concrete mix with Idrocrete KR 1000, Idrocrete KR 1000 reacts with the calcium hydroxide and other products that are formed during the hydration process of the cement, to generate compounds of calcium silicate and other non-soluble salts. Theses crystalline compounds and calcium silicate hydrate are deposited in the voids of the cement matrix and reduce its total porosity, thereby increasing the resistance of the concrete to the penetration of water under pressure.

APPLICATIONS:

Idrocrete KR1000 can be successfully used to produce concrete for the following applications:

Idrocrete KR1000 can be successfully used to produce concrete for the following applications:

• dams;

• bridges;

• car parks;

• storage tanks;

• pipes and piles;

• retaining walls;

• tunnels;

• marine structures;

• basements and foundations;

• swimming pools;

• precast elements; etc.

For best results, Idrocrete KR1000 must only be used in concrete that has been correctly designed with two basic rules to produce impermeable concrete, water/cement ratio of less than 0.5 and adequate wet curing time.

The crack bridging ability of Idrocrete KR 1000 allows to close microcracks up to 0.4 mm.

APPLICATION METHOD: Idrocrete KR 1000 is added to the concrete mix just like any other type of powder admixture. The product must be added in the concrete mixer or in the truck mixer together with all the other components (cement, admixtures and aggregates). Once Idrocrete KR 1000 has been added, we recommend extending the adequate mixing time so that the admixture is evenly blended throughout the mix.

COMPATIBILITY: Idrocrete KR 1000 is compatible with all WR and HRWR admixtures; for quality concrete we recommend use of Mapei concrete admixtures-Mapeplast, Mapefluid and Dynamon ranges.

DOSAGE: The recommended dosage rate for Idrocrete KR 1000 is 1 to 3 % by weight of cementitious materials. For best results we recommend laboratory trials with site raw materials at different dosage.

August 20, 2020. 2:52 PM

April 15, 2019. 7:35 AM

Comments

Load more comments