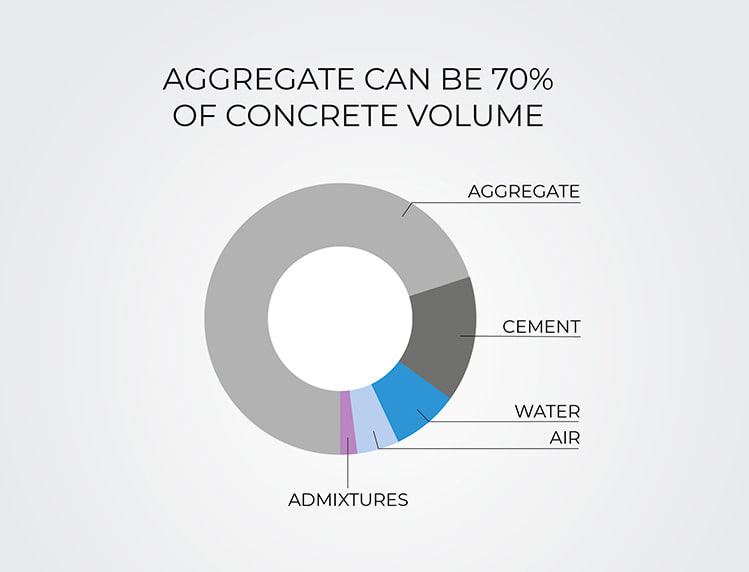

Fine and coarse aggregates, sand and stones, make up 60-70% of the raw materials in a concrete mix.

Local sourcing is an economical and sustainable solution, though not always viable due to unfavorable characteristics of the materials available. Aggregates can have contamination, unfavorable gradation, clay particles, which affect durability and pumpability.

The use of mineral additions as supplemental cementitious materials, like fly ash, slag, silica fume, metakaolin, natural pozzolan, all improve the performance and the durability of a concrete structure, by enhancing sustainability and delivering economic savings. Mapei offers a range of mineral products, such as Mapeplast PZ 300 and Mapeplast SF, designed to:

Mapei offers specifically designed highly effective water reducers that work in combination with recycled aggregates. The products from the ReCon Agg portfolio are particularly suitable for concrete designed with recycled aggregates.

Replacement of Portland cement with by-products like fly ash or blast-furnace slag requires concrete hardening activation. Mapei offers the latest-generation activators based on homogenous nucleation such as Mapefast Ultra, whose benefits are multi-functional:

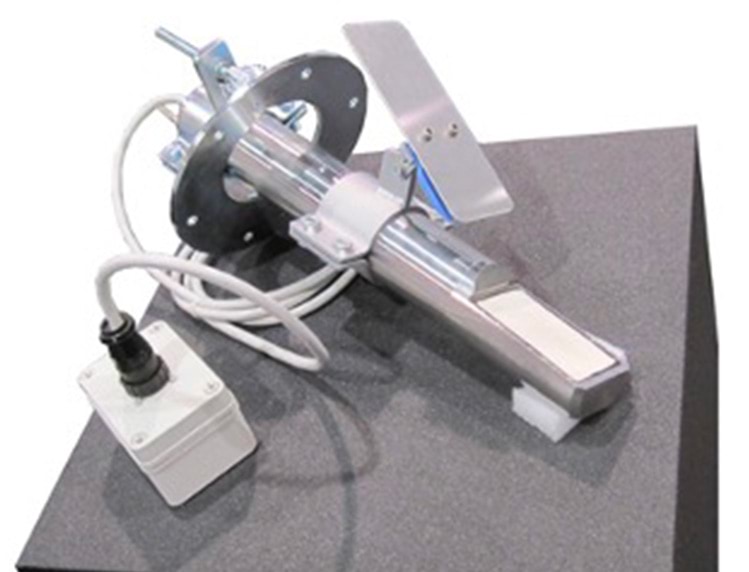

Precise evaluation of water content in the aggregate at mixing, represents one of the most difficult challenges in the automation of concrete production. Deviation leads to variable quality, increased cement consumption, and a higher carbon footprint.

Mapei offers customers remote tank control to reduce the carbon footprint by optimizing the transport.